|

08-23-2021, 09:10 PM

08-23-2021, 09:10 PM

|

#1

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

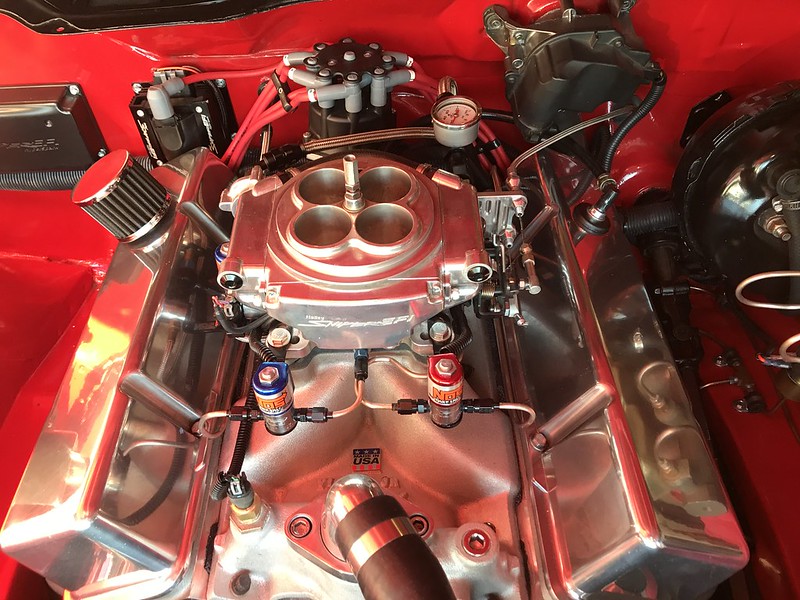

Nitrous system for the 406 sbc

Those of you who have followed my build thread over the past two years, know that I have always planned on putting a single stage wet nitrous system onto the engine. Here is a link to the build thread in case you want to read it or find all the engine/powertrain/car information. http://www.njfboa.org/forums/showthread.php?t=69033 The goal for this car has always been a naturally aspirate mid-high 11's in the 1/4 mile , and then mid-high 10's on a single stage of nitrous. I am not a bracket racer, just simply a fella chasing a timeslip.

Anyways, the time has come for me to get this going. I am certainly no expert with nitrous, but I did run nitrous on the old 305 TPI engine for about 4 years. It made the 305 fun, but I basically just played around with it on the street, during autocross, and some drag racing. That kit was the NOS Powershot, which had 100 hp jets and 150 hp jets. Here is a link to the kit on Jegs: https://www.jegs.com/i/NOS/741/05151...QaAnd9EALw_wcB

So, I still have everything from this setup, and for my upcoming "version 1" of this upcoming nitrous system, I will be using most of the components. Instead of just drilling the engine with a 200 or 250 shot and having to buy new solenoids, I feel safer using the existing "smaller" solenoids for at least this fall 2021 season. I will be using the existing 10 pound bottle, its blow-down tube, the bottle pressure gauge and the main -4an fed line from the bottle. I also will be using my toggle switch setup that is mounted in the ashtray. I do not yet want a bottle heater, and I will never need a remote bottle opener since I can reach the bottle valve from my drivers seat. As mentioned, the NOS powershot solenoids are good for somewhere in the neighborhood of 150 hp (but I have read 175 can be done) so I will use those, along with the nitrous purge solenoid. I bought a NOS cheater wet-plate from a guy on thirdgen.org for $50 which was a heck of a deal. The wiring, and the relay will all be replaced with fresh new stuff, some colder spark plugs, and a new oxygen sensor with an O2 extender bung is also required. I am on the fence about using a fuel pressure safety switch, because I know it is a good idea, but mounting it in the tight area where I will have the fuel lines just might not work for me. I also do not plan to use a throttle mounted "window" activation switch, as I can control the nitrous both with my shifter mounted button AND also with the holley efi software.

I have been reading a lot about nitrous while using the holley sniper efi and I will get into some of that later. UNsure if I will be doing a progressive shot or not yet; maybe. This post is mostly for me to lay out the components and gameplan for everyone to look at, and then let me know their thoughts and technical opinions.

Bottle:

Use existing 10 pound NOS bottle with blow down tube.

Toggle switches:

Using the existing Nitrous Outlet ash-tray panel. I only plan to use the "master arming switch" and the "purge button". https://nitrousoutlet.com/i-30559860...tch-panel.html

Fuel Pressure safety switch:

undecided currently, but I will Probably get one

https://nitrousoutlet.com/i-30559952...-manifold.html

Oxygen sensor:

The nitrous guys that run the holley efi assure me that I will need a better O2 sensor as well as a special extender. (will add link later)

Lines/Plumbing:

I had used the braided -3an lines that came with the TPI kit on the TPI and they were good. They are way too long for my new setup. Instead of shortening them, I think i want to go with a hardline from the solenoids to the plate. Will do the -an flex lines to connect the fuel system to the solenoid, and to connect the nitrous bottle to the purge solenoid. But everything else I want to do with hardline.

- I am going to have to find a spot I am happy with to mount the solenoids in a spot that not only is visually appealing, but also serviceable and allows me to change jets easily. Therefore, instead of fighting with stainless steel lines at first, I might try to use some of my 3/16" (which is -3an) copper-nickel lines that remains from when I built my brake lines throughout the car. I have emailed Nitrous Express AND Nitrous Solutions who both told me that copper-nickle line is absolutely fine to use for hardline on a nitrous/fuel system. It will be much easier to bend, flare, and work with. However, they will not be shiny silver. If I can get the lines the way I want, maybe later I can re-create them with stainless. I will need to buy the proper fittings, tube nuts, and adapters. I also will need to buy a cheap-o 37degree flare tool, but I do have a tube bender already.

- Fuel line fittings will be needed too to T-off of the existing -8 fuel feed line. I will also re-install my Aeromotive fuel pressure gauge, and probably that fuel pressure safety switch, so it will be a cluttered area of fuel fittings and adapters.

Solenoid Locations/brackets:

This one is tricky, and right now I have about 3 possible options, but feel free to add in your suggestions. Number 1 priority is that the solenoids have to be mounted in a way that are visually appealing to me. I don't want to just have all sorts of brackets in random places with solenoids and lines hanging all over the top of the engine. No way. There are not too many choices that appeal to me, and maybe I could make my own later, but for now, I might use something like these and "drop-mount" them off the carb-mount studs. https://www.holley.com/products/nitr...parts/16523NOS Initially i wanted the solenoids all in that "valley" between the sniper and the thermostat housing. IT will get real tricky to make all the plumbing work that way, so I don't think its a realistic option. Also, the purge solenoid should be very close to the nitrous solenoid, so keep that in mind.

- Nitrous plate:

NOS cheater plate which i got for $50. It is capable of flowing up to a 250 hp wet shot, which is all I ever plan to put to this engine. link: https://www.jegs.com/i/NOS/741/12500...AaAkwmEALw_wcB I will buy some spare 4150 carb gaskets too for fresh gaskets during the install.

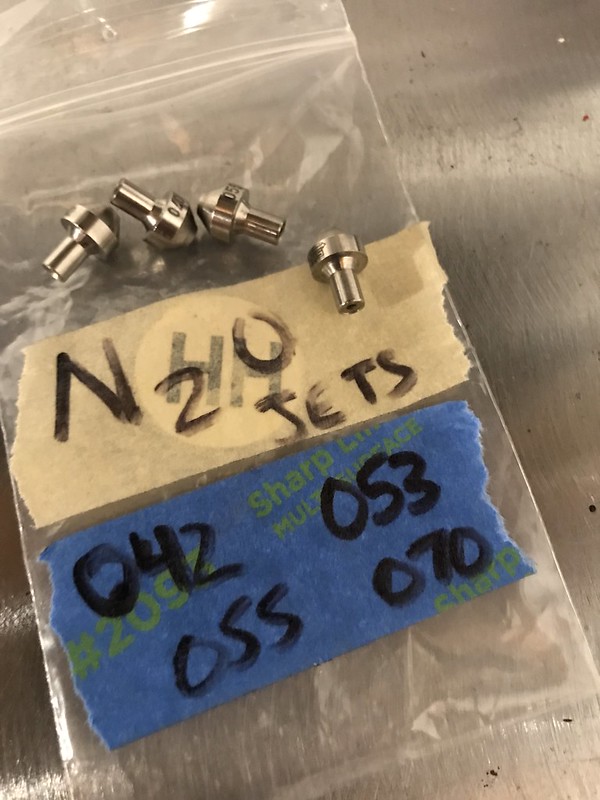

Jets:

The olde TPI kit came with two set of jets 042 + 053 jets for the 100 shot, and 055 + 070 for the 150 shot . I am unsure if these jets will work for the cheater plate, because I read this link which tells me different jetting :

https://www.429-460.com/t25799-new-n...-cheater-plate

Nitrous Solenoid Driver (not a Relay) and wiring:

The NOS TPI kit came with a 30a/50a 12v relay which I am sure still works, but the Holley EFI system seems to require a high-current nitrous solenoid driver instead of a relay? interesting.

https://www.holley.com/products/fuel.../parts/554-111

Spark Plugs:

I have only ever used the Autolite 3924 spark plugs on this engine, as these were the engine builders recommendation. The next step colder would be an Autolite 3923 plug, so I think I will go with these. https://www.summitracing.com/parts/atl-3923

Chris Meyer of EFI systemsPro has a great article on all of this too:

https://www.efisystempro.com/efi-pro...-nitrous-oxide

OR

__________________

1987 IROC-Z - modified

|

|

|

08-27-2021, 09:25 PM

08-27-2021, 09:25 PM

|

#2

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Stopped by Bruce's speed shop today to get my 10 pound bottle filled. I had emptied it down to zero so it was dead empty. Bruce now charges for nitrous by the pound, which is good, because I will just need to get the bottle topped off from time-to-time and not need a full fill. I am considering a second bottle to keep as a spare full bottle, as this will cut my trips to his shop in half. new bottles are expensive thought at $300 a piece! yikes

UPS brought my summit racing order today.

-sidenote: I will be returning the $290 NTK wideband oxygen sensor. I had done a bunch of research on the Holley EFi websites and the NTK sensor is highly recommended for nitrous(forced induction) setups. Yet, just today I spoke with one of the top tech guys via email who told me that the NTK sensor is compatible with all other holley EFI systems, however it is NOT compatible with the holley sniper system. So, I verified, that my best course of action is to use the Innovate HBX-1 extender along with my current oem holley bosch sensor. It will be good to go. So, I might take the money from the returned sensor and either buy a second nitrous bottle, OR buy a removable bottle heater. Those bottle mounts with the bottle heater built in are cool too, but way too expensive for me. There seems to be a lot of bottle heater options, so I will have to do some research on that topic.

Hope to make some progress this weekend with mounting and wiring, that way i can figure out what fittings I need to order. Also, still waiting on the fuel pressure safety switch to arrive, delivery scheduled for next Thursday.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 08-27-2021 at 10:04 PM.

|

|

|

08-28-2021, 07:55 PM

08-28-2021, 07:55 PM

|

#3

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 08-28-2021 at 08:04 PM.

|

|

|

08-29-2021, 03:05 PM

08-29-2021, 03:05 PM

|

#4

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

I am not all that familiar with the sniper you have, but does it not have a fuel pressure input and or, safety setup for that?

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

08-29-2021, 08:07 PM

08-29-2021, 08:07 PM

|

#5

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

there are a lot of safety deactivations that I can program in the sniper software, but sadly one of them is not fuel pressure. The terminator and other Holley systems do monitor fuel pressure, but unfortunately the sniper does not. I can program it to kill the nitous at certain rpms, throttle position percentages, rich/lean afr conditions, and of course if I stop holding my momentary switch on the shifter. It would be awesome if the sniper monitored fuel pressure and could kill the nitrous system if it sensed low pressure, but I am thinking that the low fuel pressure would also cause a lean condition and therefore THAT would disable the nitrous? And/or I can install the fuel pressure safety switch, but on one hand it is just more components, more wiring, and more connections to make in an already crowded area. Some sniper nitrous guys don't use a fuel pressure safety switch and some do.

Got most of the engine bay wiring done today. Wired up the nitrous driver solenoid, the power and ground wires to the nitrous/fuel solenoids, and the purge solenoid too. Gotta finish covering everything in protective split-loom, and then run some wires into the cabin to my buttons.

Gotta place the order for the -an fittings too, maybe later tonight. Gotta also change the spark plugs and then start to get into the holley software to build a base tune. Oh, and also, I gotta order some nitrous jets. have yet to do the math on what jets I'll need for a 100, 150, and 175 shot, with a fuel pressure at 60psi.

__________________

1987 IROC-Z - modified

|

|

|

08-31-2021, 08:30 PM

08-31-2021, 08:30 PM

|

#6

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

fittings ordered and will arrive tomorrow. There is a lot of them and I am not thrilled about having that may connections to make on the fuel and nitrous systems, but I will take my time and do it as neat/properly as possible. It is a lot though... but that is because I am using 3/16" hard-line. if I was just using the -an braided hoses, there would be less fittings, but then I would have swoopy "messy" lines all curling about in a very confined area. Not desirable for me.

Also ordered some jets after doing some calculations to figure out what will work for a 75 shot, 100, 125, 150 shot. Some of the jets I already have will work too, so I only had to order about 6 jets for now.

Was going to install the Autolite 3923 spark plugs, but I was hesitant to do so after checking the gap on them when Itook them out of the box. They appear to be factory gapped at about .038 to .040 and I think that is too big of a gap. probably ok for N/A, but for a small nitrous shot, I would think I should go .030 or so. Thoughts?

Took care of about 95% of the wiring too. Well, actually 100% if I do decide NOT to use the fuel pressure safety switch. If I do decide to use it, I will have to decide if I should wire it in with the (master-arming switch -> ecu) or (momentary switch on the shifter -> ecu) Not sure if it matters, and still not even sure I want to install it. Some of the EFI and nitrous gurus I've talked to elsewhere say that the switch isn't necessary, and other people seem to like having multiple safety features in place. Again, keep in mind, the sniper ecu will instantly kill the nitrous if it reaches my lean-cutoff parameters.

In wiring the nitrous to the ecu, I had to loose my 2-step rev limiter because that occupied my input#2 spot of the 10 pin sniper connector. I'm ok with not having a 2-step as I am just foot brake launching at 1,800 rpms anyway.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 08-31-2021 at 08:33 PM.

|

|

|

09-02-2021, 08:23 PM

09-02-2021, 08:23 PM

|

#7

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Fittings arrived very late in the day yesterday, so I didn't get to install anything until after work today. Again, its a LOT of fittings, but that is because every hard-line connection needs a tube-nut and tube-sleeve...also every connection at the solenoids needs a NPT-to-3an adapter. I also bought some extras just in case one or two get boogered up accidentally. Started mocking things up on the nitrous side today, and most of it is in place, and some of it is tightened down. Tomorrow I hope to make some progress on the fuel side of things. Had some ideas of where I wanted the purge line to purge, and I think I might get creative and use some of my old fittings to make a dual-purge setup that comes out from the cowl area. the fittings and lines would be hidden below where the windshield wipers rest with that mesh screening covering the open void. I am short a single -4male to -3 male fitting, I am hoping I can get it over at Bruce's speed shop this weekend. if not, I will just do a single purge pipe for now, and then add in a T-fitting (with the -4 to -3 adapter) later. I know, a LOT of fittings and a lot of connections for possible leaks. Maybe this will all get changed later in the future, so this is version1. Any comments or advice, feel free to let me know.

Jets I now have: .021, .024, .029, .032, .042, .050, .055, .062

The combinations I came up with for my 60 psi fuel pressure setup is:

75 shot = .042 nitrous + .021 fuel

100 shot = .050 nitrous + .024 fuel

125 shot = .055 nitrous + .029 fuel

150 shot = .062 nitrous + .032 fuel

I still am curious about the spark plug gap too, any thoughts (see post above this)

Worked up a quick tune file for a small 75 wet-progressive test shot. Set up some safety parameters or failsafes too. Keep in mind, that I will be letting off the button and not spraying nitrous during the gear-shifts. Therefore the computer will see this as "pedaling" and I have to account for that as I put in some of the values in tune (screenshots below)

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 09-02-2021 at 10:05 PM.

|

|

|

09-03-2021, 08:33 PM

09-03-2021, 08:33 PM

|

#8

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

well this is exciting for me at least, not sure if anyone else is enjoying! Sorry for all my excessive typing and posting, just showing my progress and in case anyone has any tech advice, I would rather they see what I am putting on the forum, and send over any advice as I progress.

Got the fuel side plumbed up today. A couple complicated bends. Turned out pretty good, but I will eventually make some neater lines for version2. Decided to do a dual purge since I had hard-line and fittings. I only needed one additional specific fitting, so a quick ride over to Bruce's speed shop in Rockaway, and bought it. Buttoned everything up and pressure tested the nitrous side by turning on the bottle. No leaks at all at any of the fittings, and the dual purge worked as intended, had my wife test it. Primed the fuel system and it shot to 60 psi on my in-line gauge, then dropped down to about 45 after 5 seconds, and then slowly dropped to 22 psi where it held for about an hour, until I primed it again and it still held. No leaks at any of the fittings either.

Peeled off the protective blue tape, zip tied a few things up, put all the spark plug wires on and checked fluids. Loaded up that "baby" progressive 75 shot tune (see above). Engine ran fine as normal, even with the new colder plugs it acted the same. After warm up I only had time for a quick test drive just to make sure all the systems (lines, fittings, electronics, tune, etc) functioned properly. Did a brief test rip and it took it just fine. I know a slow progressive ramped 75 shot is hardly anything, but it was nice to feel it come in, and to smell that smell of burnt nitrous in the exhaust fumes. Will examine the datalogs soon, as well as pull out some plugs and see how they look too.

I do have some cleanup to do under the hood still, so this isn't the final result, but it is a working system. Also, would like to polish the valve covers, sniper unit, and whatnot. Car show season and some Test -n-tune nights are coming up soon.

__________________

1987 IROC-Z - modified

|

|

|

09-04-2021, 08:26 AM

09-04-2021, 08:26 AM

|

#9

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,341

|

Looks like your wife’s car needs a purge kit, too

|

|

|

09-04-2021, 08:30 AM

09-04-2021, 08:30 AM

|

#10

|

Join Date: Sep 2010

Location: Hackettstown, NJ

Posts: 165

|

Looks great Dave.

Now some cool fall air and some test & tune @ Island. Good luck

__________________

57 Chevy - 210 - 355 SBC-Powerglide-10 Bolt 3:73 Gears - 12.78 best et - 104.78 MPH-street driven

80 Firebird-350 SBC-Turbo 350-10 Bolt 3:42 Gear - 13.69 best et @ 97.52 MPH

96 Buick Roadmaster wagon LT-1 - (DD) for sale

2023 Equinox - wifey's car

22-Ford Maverick-FWD Eco

|

|

|

09-06-2021, 08:41 PM

09-06-2021, 08:41 PM

|

#11

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

thanks fellas. Took the car out for a few quick test runs locally. A progressive 75 shot, a fixed 75 shot, and then two brief fixed 100 shots. It pulls hard, I love it. I took some datalogs, and I am still trying to learn how to understand a nitrous datalog. Mostly to make sure my AFR is safe and the engine is happy. I also pulled plugs after the 75 shots and those looked good to me. I Probably should either buy one of those magnifying glasses with a light on it, or start using the hole-saw method to cut the plugs apart and see the fire ring on the porcelain. Timing marks on the ground strap are right at the bend of the strap, and my timing is fixed at 32 deg when the nitrous is on. Normally is it is at 34.5 deg at wot, and on the log, the bright yellow "flatter line (upper graph) is my actual timing. The darker-yellow colored "box shaped" line (lower graph) is when i am actually spraying the nitrous, the light blue "box shaped" line (upper graph) is telling me that my "timing modifier" feature is active, and I have it to hold the fixed 32 deg timing for .5 seconds AFTER I am off of the button.

Also, I am currently NOT spraying during the shifts, but on track day I probably will keep the button down during the shifts. The AFR trace seems to have lot of spikes when i am on the nitrous, so I have to find out if that is "normal during nitrous" or not. I thought there was a way I could smooth the data-points, but I can not seem to figure out how. I'm sure I will get all this sorted out soon enough, but in case anyone had any input on reading a nitrous datalog, feel free to let me know your technical thoughts. Thanks

I do think I will end up using the $ that I got from returning the expensive oxygen sensor towards a bottle heater. As discussed above, it would certainly help me maintain a more consistent bottle pressure and I would also need less trips to Bruce's to get the nitrous bottle filled.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 09-06-2021 at 08:48 PM.

|

|

|

09-07-2021, 06:01 AM

09-07-2021, 06:01 AM

|

#12

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

On the Y axis tags on the left of your data log, click the parameter you want to change. Then change the smoothing to a value that calms down the line diagram.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

09-08-2021, 09:03 PM

09-08-2021, 09:03 PM

|

#13

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

thats it !! thats exactly what I was looking for. thanks

I changed that to a smoothed 5point log and everything did exactly what you said. it calmed down the log and I get a better picture. I also decided to change the CL comp advanced control from a 3 to a 4. This will slow down the "response" because it seems mine reacts too quick and overcompensates, and then catches itself and undercompensates .. basically that in a repeating cycle. I will see what setting 4 does, and possibly even try out setting 5 if needed.

Nitrous Outlet Bottle heater kit arrives tomorrow so I will hopefully get to install it on Friday. Car show this Saturday, but possibly next weekend I might take the car to the track for a test and tune event. Hoping I don't blow my tiny exhaust pipes apart.

__________________

1987 IROC-Z - modified

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|

|