|

|

03-18-2019, 03:57 PM

03-18-2019, 03:57 PM

|

#276

|

|

Ayatollah of Rock N Rolla / Admin

Join Date: Mar 2006

Location: Parts Unknown

Posts: 12,573

|

Quote:

Originally Posted by Blackbirdws6

I was in rare form. Good no one was around.

The damn nut strips out too easily. Where my oil filter sits relative to header and oil pan kick out, getting anything in there is a total PITA let alone getting leverage to do what needed to be done. The first time it happened I was using a 12 pt socket when I should have just found a 5 pt. This time around, it just didn't want to come off. I am always careful to not go ham on tightening these for that exact issue. I had a Wix in stock so that went in.

When I go for the lexan windshield.

|

Gotcha. Wasn't sure if there was a performance issue with the filter itself. I've had the same issue with them- the nut itself seems shallow and pre-rounded.

|

|

|

03-18-2019, 04:05 PM

03-18-2019, 04:05 PM

|

#277

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Quote:

Originally Posted by WildBillyT

Gotcha. Wasn't sure if there was a performance issue with the filter itself. I've had the same issue with them- the nut itself seems shallow and pre-rounded.

|

It wouldn't have been a big deal aside from the lack of access. I like the larger size of the filter but done with the stupid nut design.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

03-18-2019, 04:41 PM

03-18-2019, 04:41 PM

|

#278

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,342

|

Why did you yank ac?

|

|

|

03-18-2019, 05:46 PM

03-18-2019, 05:46 PM

|

#279

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Quote:

Originally Posted by sweetbmxrider

Why did you yank ac?

|

Used it once since you charged it, drive with top down about 99% of the time, kids think it's racecar and I actually like the cleaner look.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

03-18-2019, 07:35 PM

03-18-2019, 07:35 PM

|

#280

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Damn kids.

When does the nitrous kit go on?

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

03-18-2019, 07:36 PM

03-18-2019, 07:36 PM

|

#281

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

whew! thats a nice update. didnt know what you had planned for the main car of your ever growing fleet.. but thats some good stuff. had never heard of that white heat coating on the headers. let us know how it works out after a year of use etc.

__________________

1987 IROC-Z - modified

|

|

|

03-18-2019, 09:50 PM

03-18-2019, 09:50 PM

|

#282

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Quote:

Originally Posted by LTb1ow

Damn kids.

When does the nitrous kit go on?

|

When your car goes faster than mine.

Quote:

Originally Posted by IROCZman15

whew! thats a nice update. didnt know what you had planned for the main car of your ever growing fleet.. but thats some good stuff. had never heard of that white heat coating on the headers. let us know how it works out after a year of use etc.

|

We will see how it lasts and for the cost....it better. The coating sure is tough. I beat the crap out of the driver side header and the coating somehow held up. Let's see how it does after some LTx nuclear level heat.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

03-19-2019, 09:01 PM

03-19-2019, 09:01 PM

|

#283

|

|

11 Second Club

Join Date: Feb 2007

Location: elmer

Posts: 274

|

But why male models ?

__________________

87 TURBO T-- 02 Z28

|

|

|

06-14-2019, 05:05 PM

06-14-2019, 05:05 PM

|

#284

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

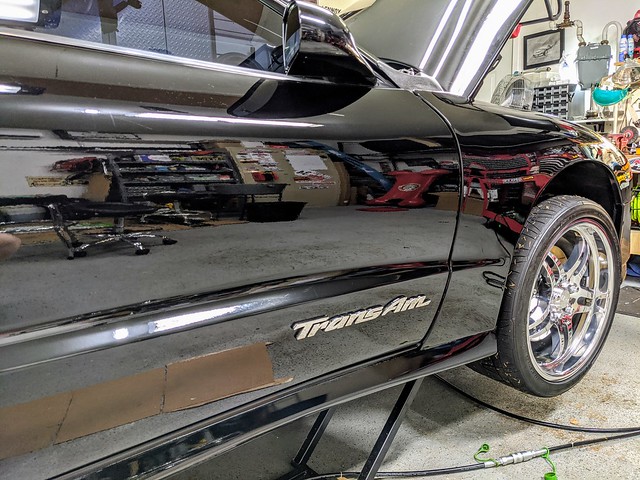

Soooo it's been a while and a good bit has been happening behind the scenes for those not following on IG/FB. Normally I'm better about taking pics and posting progress but it just didn't happen well this time. For those that care and like a story, here is the run through of where we are today.

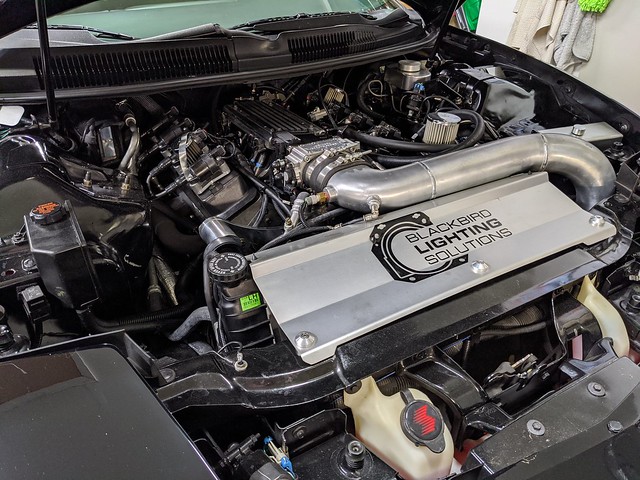

Last you saw, the AC was removed and like most of you that know me, I couldn't just go for the cheap $30 A/C delete pulley nor the "backyard fab" accessory bracket for that slick low mount style. No I had to go for the pricey pulley set machined from billet to serve my needs and lighten my wallet.

I didn't like how the power steering pump pulley looked so this little gem got the nod as well.

I then ventured off into buying a bunch of heavy welding wire cable, crimping/cutting tools, eyelets, etc to finalize the connections throughout the car. As you may recall, Adam was kind enough to help run the main wires through the interior and Kirk swung up for half an evening to get the relocated battery box in it's final resting place along with the cutoff switch. Adam's idea of trying to mount the switch so that the rod would go through the trunk key lock panned out very well so that's what we did. Kirk machined the rod to the appropriate length so that all came out great.

Since all the big decisions were made, most of the rest of the work was up to me due to schedule conflicts and other more important life events.

Exhaust:

When Smash was here, the headers came out fairly easy on the drivers side but the passenger side was a bitch. I decided since I was doing this solo, I would start on the hard side so as not to end up tired and frustrated when I needed my sanity and energy the most. Well that didn't go as planned. The passenger side went in fairly well but the drivers side was a fight. I can't remember a time I was more angry and frustrated. During my attempt to install it, I managed to wedge it into a position that I swore would require something to be cut. After calming myself down more times than I care to mention, I somehow got it free and didn't destroy the coating in the process. I managed to get the header in with some painters tape and persuasion however the oil filter took a good hit and needed to be replaced.

Sweaty and very tired, I look up at the oil filter and have no idea why I'm seeing a K&N unit with the stupid nut at the bottom. I swore off of these after my last issue with the dumb nut but I guess the inner cheap in me made me use one I probably had in stock. I took my time and was careful but sure enough, the nut stripped so I was in for another fight. That battle ended the same evening but in the end, I was pretty shocked I got these things done.

Next came the y-pipe which was thankfully straightforward in getting some fresh gaskets and RTV high temp on the tail end.

Battery/Wiring:

Battery/Wiring:

As mentioned, Kirk helped get the position of everything finalized which was a huge help. He installed the power/ground jump leads on the bottom of the car so should I have an issue with the battery, I can get the vehicle power/started or just get the damn trunk open. Remember this is a vert and I'm a husky gentleman so slipping through the area into the trunk with cables won't be fun or possible.

Next you will see where the cutoff switch was mounted under the trunk lid release.

Next we have the almost finished product. I removed the CD changer and rescued the mix CD's I had in there for future.

Now I know what you may say....but Brian, where did your subs go. Don't worry, I will be finding a way to get at least one sub back in the trunk. I am likely just going to cut the box and recarpet it so it fits between the battery and other side of the trunk well.

Finished switch rod

For now, I'm keeping it in and can easily unscrew it when not at the racetrack. I want to get something nice to plug the hole when not in use.

Adam came up and helped finalize some of the wire connections up front since I was generally gun shy about making the final cuts. He did a great job replacing the power block with a new one hidden in the fender well. I didn't get a pic of it before installing the fender line and for that I'm sorry.

We were hopefully of getting a first re-start on this day but as I was tightening the nut for the starter power post, I heard a couple small cracks. I didn't realize what it was until things got very loose.

I debated ordering a new starter or replacing just the solenoid. A new one was only a little over $100 so I figured why not. The new Amazon Delco professional unit arrived and was nearly outside the box. They decided to ship it in the OE box which wasn't fit for transport. While it looked generally OK, I wasn't happy. A couple phone calls later and I got a refund plus they didn't want it back....OK sure!

Since my OG starter worked fine minus the new window, Smash said why not swap the solenoid. A few stubborn bolts later on the new unit and some grinding for access and I had it off. The starter was now in and secured but required a bit too many spacers for my liking due to the new big cables.

I connected new grounds in the front of the car and utilized existing holes in the block and the sway bar mounts that no longer had any use. For the rear, holes were drilled in the framerail but later they received welded studs for a nice secure connection.

Accessory Bracket:

No instructions were included so I was looking at a bag of various hardware, different length bolts, washers, etc. This was definitely one of those install it and redo things as you go situation. Eventually everything found there home and I really love the look and access provided. A friend on Facebook with the same setup provide a ton of helpful pics which were invaluable to shortening the install process.

Everything looked pretty well lined up but that wasn't the case. The crank pulley sits just a bit out from everything (always has) so when Adam came up, he helped me add spacers to the bracket. Now all is well.

There are many other things I will include in another post, include a weird starting issue, but its Friday and Miller time.

Here are some pics to take you into the weekend.

And most importantly....

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

06-16-2019, 07:00 PM

06-16-2019, 07:00 PM

|

#285

|

|

Power Member / trans break does not equal transbrake

Join Date: May 2009

Location: The Meadowlands

Posts: 4,513

|

1. Can you link me to all things used for the jump leads below the rear bumper? Id like to add those as well since i have to rear lock cyl either.

2. our cars are complete opposites. you figure what parts you want and get everything together on your own, then the pals help with the install. While i have a team of pal advisors on what to do, but am left to do all the install my self.

3.

__________________

99 Z28 - SBE LS1/60e

Motor - 10.84 @ 128 - 1.47 60'

Nitrous - 10.16 @ 132 - 1.40 60"

Last edited by LS1ow; 06-16-2019 at 07:00 PM.

|

|

|

06-17-2019, 09:15 AM

06-17-2019, 09:15 AM

|

#286

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Quote:

Originally Posted by LS1ow

1. Can you link me to all things used for the jump leads below the rear bumper? Id like to add those as well since i have to rear lock cyl either.

2. our cars are complete opposites. you figure what parts you want and get everything together on your own, then the pals help with the install. While i have a team of pal advisors on what to do, but am left to do all the install my self.

3.

|

1. Sent you a link via text.

2. I still consult and you don't end up with a built LTx without having a few screws loose. I don't hide the fact that I need help with things but I do so for a few reasons. 1) I may know generally what to do when it comes to "car things" however my execution is hindered when working on the Bird. I overthink it all and don't/can't commit. I seem to do much better working on literally anything else. 2) I enjoy time with Pals and sometimes working on something is the excuse. You don't really know my father but it's a DeLuca tradition to "do things" while hanging out. There is very minimal chill with us unfortunately. 3) Physically I need to watch that I don't end up hunched over in a wheel chair drifting into an opioid induced coma.

3. You're making some big changes while I'm just optimizing what I have. I think this will come down to whether your car survives the changes and future abuse.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

06-17-2019, 07:26 PM

06-17-2019, 07:26 PM

|

#287

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

awesome update. good work dude!

I will be venturing into the battery relocation and on/off switch this winter as well. I haven't done too much research on it yet, but i'll revisit your thread and ask some questions when its time.

__________________

1987 IROC-Z - modified

|

|

|

07-10-2019, 10:36 AM

07-10-2019, 10:36 AM

|

#288

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

TL;DR - Long term voltage issue with high RPM, alternator being spun too high, replaced alternator with proper pulley, life is good.

Long read:

Quick update. I've noticed a battery voltage issue even before the relocation of the battery where with RPM, I would see volts gradually drop during a pull. It never seemed to cause an issue with how the car ran but always bugged me. I was thinking it could have been poor belt alignment causing belt slip (always been off a rib on the balancer). I've lived with it for years since the blower first went on the car. The belt never chucked itself and it all worked so life went on.

Since I have this new bracket, now was the time to get the alignment right. Even with the alignment where it needs to be, volts still dropped during a pull which was enough to trigger the check gauges light on the dash.

After doing a bit of reading, it seemed that I may have a couple issues. One being that my alternator may be a bit tired but more prominently, I may be overspinning the alternator causing it to essentially shut down. Doing some quick math and guessing at the pulley size I had on the car, I was likely spinning the alternator to somewhere in the 22k+ range in the upper RPMs. Not good as most only want to spin to 16-18k. Oops.

Assuming the current alternator was trashed, I decided to spend money (Not shocking I know), and grabbed a 200A unit from Powermaster in matte black. I spoke to their tech folks who were very helpful and after doing the math, I needed to grab their 2.5" pulley to keep the idle and upper RPM speed within spec. A few days later, Summit got the package to me and Smash came up to toss it in. I was actually going to tackle this one myself but I decided to slip a disc in my back this prior weekend and while I was doing much better, needed to take it easy.

New alternator went in and guess what, it worked!! Volts were strong at idle and after taking it for a ride yesterday evening, voltage did not drop at all up to near redline. I also was dealing with a fuel pressure drop in the upper RPM range; I assume associated with the reduced voltage from the charging system. That is also cured as well. The fuel system has provided enough fuel but its not a good look to see the pressure dip when you likely need/want it the most.

One less thing....

Quote:

Originally Posted by IROCZman15

awesome update. good work dude!

I will be venturing into the battery relocation and on/off switch this winter as well. I haven't done too much research on it yet, but i'll revisit your thread and ask some questions when its time.

|

Thanks!

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

07-12-2019, 06:45 PM

07-12-2019, 06:45 PM

|

#289

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Certainly quite the jig saw you gots. Shiny and billet but complex

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

07-20-2020, 03:02 PM

07-20-2020, 03:02 PM

|

#290

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Well it’s been some time since I last updated this thread so here goes.

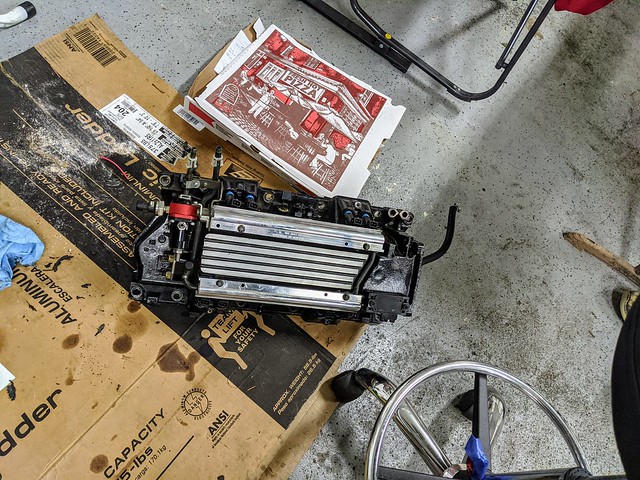

As some are aware, my after Racewars situation wasn’t too good. The car literally decided to break itself on the trailer ride home which resulted in me not being able to get the car into any gear. After a lovely 35 pt k-turn, I got it pushed into the garage to be looked at another day. What I thought was a clutch hydraulic issue turned out to be something much more significant.

After much debate, the trans was begrudging pulled to see what the heck happened as the issues all appeared to be related to a trashed pilot bearing. Sure enough…..yep.

Car work Car work by Brian DeLuca, on Flickr

But wait, there was more….. as I went to remove the flywheel, I noticed the outside of the flywheel bolts got kissed by the lower clutch disc. Now when this whole setup went together, Monster specifically said to use factory GM flywheel bolts as using anything else (ARP included), will make contact. I noticed a few other questionable concerns with the clutch wear but in the end, Monster made good on the situation and addressed the problem with essentially a new clutch, new bolts (machined) with some changes in the machine work of the flywheel.

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

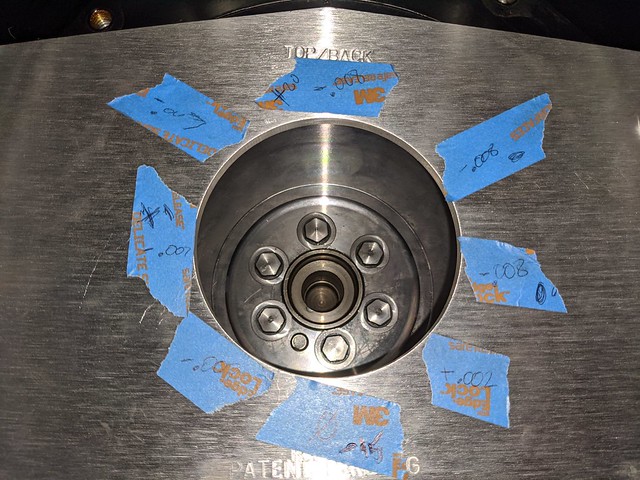

Since the trans was out, I figured it would be good to just have that gone through to avoid a situation where it goes back in and needs to come back out should something be wrong. I thought the issue was caught early enough but oh no, that’s not my luck and it turns out a decent amount of components needed to be replaced (input cluster, input shaft, bearings and few other odds/ends). I’m glad I had it gone through but my wallet did not appreciate it. There were ideas as to why the bearing failed which could have just been a bad $25 part or perhaps the bellhousing runout was out of spec. After watching all of the videos on this topic (new to me), the pic below is where things ended up and in short, the bell was without spec and no offset dowels were needed.

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

New clutch going in.

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

This time around, I decided to go with a pilot bushing vs the bearing. If the bushing eventually wears out, it doesn’t (shouldn’t) hurt the trans like the bearing would but I recognize the useful life is shorter. So with that, back goes the clutch and trans. Word to the wise, don’t let three engineers attempt to determine shim spacing for the slave. It was definitely the weekend when this was attempted….

Car work Car work by Brian DeLuca, on Flickr

Transmission is back in and you’ll notice there is now a temp sensor in the bottom. At some point, I will have the pump kick on with temperature vs RPM so this sensor will come in handy down the road.

Also while the trans/clutch were out, I thought it would be prudent to replace the oil pan gasket as it has been weeping from the rear and while it didn’t leave a drop on the ground, it would make a small mess over time. Prior to the first ride, I did work the clutch and row through the gears while up in the air. All was well so time for a short trip around the block. There is a small loop I take around my area and by the “second lap”, I had the full James Bond smoke screen coming off the back of the car…..great…… I pull in the driveway and leave it running and peak under the car. Sure enough I have oil dripping off of the exhaust.

The next attempt appeared to be a success but I spoke too soon. Everything was looking good on start-up, at temperature, small revs, etc. so time to drive again. I get under and check after a few mile ride and damnit, oil leaking again and while not as bad, it’s way too much (actively just dripping on the ground).

Now a part of me is confident the gasket replacement didn’t go as planned due to the inability to properly prep both sealing surfaces. The pan couldn’t be dropped entirely out of the car with the K member in place, so I think the fiddly install likely was the culprit. So now after 2 failed attempts at a gasket replacement, I decide to solve the problem the only way I know how….spend more money.

I made a call to Stef’s and ordered a new custom oil pan with all the fixings. Some big positives of this pan are a thicker flange for better sealing, larger oil capacity (5.5 to 6.5qts), ability to run my low oil level sensor again, improved oil control and hell, it looks great.

Now to do this install proper, the k-member would need to come down so I grabbed an engine support that sits on the inner fenders. This proved to be a great tool.

So thanks to my great group of friends/family, the old pan came out, new pick-up installed along with the new pan. The engine support worked great and allowed the K-member bolts to be removed and it lowered out of the way enough to sneak out the old pan and install the new. We didn’t need to touch the rest of the suspension. Kirk used a unique approach to cleaning off the RTV off the bottom of the block (fire…..). The new pan went up with some right stuff RTV and torque’d to spec. K-member went up with whatever is the conversion from air to electric impact ugga duggas.

I fired the car up and so far so good….or so I thought. Adam noticed that I had a drip of coolant every 10 seconds or so coming off the head gasket (tab showing in between head/block) along with some oil leaking as well (also from between head/block). Yayyyyy……

I decide to say “screw it” and drive the car but after putting 60+ miles on it over a few days and looking underneath, its just too much leaking. The coolant wasn’t a big deal to be honest but the oil just doesn’t work for me as the car now drips on the floor and the bottom was getting quite saturated. No Bueno. Worth mentioning, the oil leak isn’t showing any significant change in the dip stick level but we know even a little oil will make a mess.

So after a good deal of prep, my friends/family once again continue to appease me and joined for a head gasket replacement “party” yesterday. Thank god I pulled the trigger on the garage AC because it just wouldn’t have gotten done otherwise.

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

That precision.....

Car work Car work by Brian DeLuca, on Flickr

I did my best to get the car reasonably prepped before the tear down. In short order, the intake was off and eventually the head revealing nothing significant. Fun fact is that with the A/C removed, the head with studs was able to be removed in car! The pistons looked good, block surface looked fine, head was OK sans a few valves that got a little hot, bores showed a nice crosshatch, etc. The MLS gasket didn’t show any blow out but that was expected given the modest issue of the leaking. There was never any mixing of fluids either. Some of the studs could have used a little more RTV but that was about it.

Everything received a good cleaning, MLS gasket coated in copper spray and all studs pulled, cleaned and smothered in RTV. The head went back on and studs torque’d in three steps. Unfortunately, just prior to this, one of the stud nuts got misplaced during disassembly which delayed the big show by about 30 mins as we all looked everywhere. Adam eagle eyed the missing nut and off we went.

Next came the intake manifold. My RTV bead on the china walls was going beautifully until someone made a well timed joke. If it leaks, we will know why….

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

Car work Car work by Brian DeLuca, on Flickr

So after all that, it was time to start it up. I fired the car up and it didn’t sound too good (running lean, not happy). Going back a bit, when the valvetrain was removed, I thought we could “cheat” and reinstall the rocker locks in the exact same position without readjusting everything. I had confidence but Smash didn’t. He was right. The other gents had left as it was well into dinner time but Smash was able to stay longer to re-adjust the valvetrain. Valve cover off, I’m rotating the engine under the car and Smash is up top adjusting. Everything is all done and I fire it up…it sounds odd and voltage is low. C’mon!

I take a look at the engine and realize we didn’t connect the main passenger side coil connector. OK let’s try this again. She fires up and there we go! Much much much better. Voltage is up where it should be and it sounds exactly as it should. I let the car get up to temp and it idles for about 5 mins. Temps never went over 185 and AFR was good. I gave it a couple very minor blips of the throttle and again, it sounds great. Smash checks under the car while its running and doesn’t see any leaks so for now, this will do. It was now 830ish so I hastily shoved everything into the corners of the garage so the V could be pulled in.

Job well done by all!!!!

Fingers crossed this is sorted for a while. I’ll likely plan some time to adjust the drivers side rockers as that would be prudent and also address a starter wire arc issue that’s been around since the battery relocation.

Car work Car work by Brian DeLuca, on Flickr

Be sure to check out Arizona Speed and Marine for all of your boat anchor parts and accessories   .

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

07-20-2020, 03:42 PM

07-20-2020, 03:42 PM

|

#291

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Still can't believe someone would take the head nut and throw it into the bell housing.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

07-20-2020, 04:44 PM

07-20-2020, 04:44 PM

|

#292

|

Join Date: Nov 2007

Location: Jackson, NJ

Posts: 1,725

|

Where are the burnout videos?

__________________

1983 camaro- Scrap

1988 camaro- Also scrap

'05 Silverado- You guessed it, scrap

1988 TRX 250R- Ported w/ high compression on 110 octane- Out 60' your LT1

Jersey Shore Street Car Takeover (JSSCT) Founder

Quote:

Originally Posted by LS1ow

and once i get PHB, what do i ajust it too?

|

Quote:

Originally Posted by Jersey Mike

Seven.

|

|

|

|

07-20-2020, 05:29 PM

07-20-2020, 05:29 PM

|

#293

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,342

|

You left the whole cheater nitrous install out of the update

|

|

|

07-20-2020, 06:04 PM

07-20-2020, 06:04 PM

|

#294

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Quote:

Originally Posted by LTb1ow

Still can't believe someone would take the head nut and throw it into the bell housing.

|

Kobe! Too soon?

Quote:

Originally Posted by wretched73

Where are the burnout videos?

|

Once clutch is fully broken in, I will be leaving some 11's on the asphalt.

Quote:

Originally Posted by sweetbmxrider

You left the whole cheater nitrous install out of the update  |

Why'd you have to ruin the surprise for Beggs???

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

07-20-2020, 09:21 PM

07-20-2020, 09:21 PM

|

#295

|

|

^^^Lover of bad cars^^^ Meet Coordinator

Join Date: Aug 2007

Location: Whitehouse Station

Posts: 2,262

|

i got beers, air conditioning, and cherry picker if anyone wants to help install a 385 for me next

__________________

1986 Honda VFR750 - 89.3HP to the wheel

2000 Trans Am M6 - Mods: Yes.

2018 Durango R/T - AFE Intake, JLT Catch Can, Stainless Works Catback, Vinyl Dodge Racing Stripes

2003 Toyota Matrix XRS M6 - Lol

|

|

|

07-20-2020, 09:35 PM

07-20-2020, 09:35 PM

|

#296

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Did you buy a motor?

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

07-20-2020, 09:35 PM

07-20-2020, 09:35 PM

|

#297

|

|

^^^Lover of bad cars^^^ Meet Coordinator

Join Date: Aug 2007

Location: Whitehouse Station

Posts: 2,262

|

Quote:

Originally Posted by LTb1ow

Did you buy a motor?

|

ya just gotta make final payment and either pick it up or get it delivered

__________________

1986 Honda VFR750 - 89.3HP to the wheel

2000 Trans Am M6 - Mods: Yes.

2018 Durango R/T - AFE Intake, JLT Catch Can, Stainless Works Catback, Vinyl Dodge Racing Stripes

2003 Toyota Matrix XRS M6 - Lol

|

|

|

07-20-2020, 10:24 PM

07-20-2020, 10:24 PM

|

#298

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

Nice job Brian and team Lt1 ! Looked like quite the scene over there. lots of parts off and removed and reinstalled. quite a day. great writeup and photos.

those blue stick-on fender protectors; I wish I had those during my project this past winter. I was constantly using painters tape and old sheets and towels on my fenders as protection. A set of those protective film coverings would have been fantastic. where can I buy?

__________________

1987 IROC-Z - modified

|

|

|

07-21-2020, 08:12 AM

07-21-2020, 08:12 AM

|

#299

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Quote:

Originally Posted by ThoR294

ya just gotta make final payment and either pick it up or get it delivered  |

Sounds like a complicated way of saying no

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

07-21-2020, 10:33 AM

07-21-2020, 10:33 AM

|

#300

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Quote:

Originally Posted by ThoR294

ya just gotta make final payment and either pick it up or get it delivered  |

No time like the present! None of us are getting any younger.

Quote:

Originally Posted by IROCZman15

Nice job Brian and team Lt1 ! Looked like quite the scene over there. lots of parts off and removed and reinstalled. quite a day. great writeup and photos.

those blue stick-on fender protectors; I wish I had those during my project this past winter. I was constantly using painters tape and old sheets and towels on my fenders as protection. A set of those protective film coverings would have been fantastic. where can I buy?

|

Yes it was organized for maybe 30 mins and then there was not a good amount of room to place things out of the way. I'm a bit surprised all that was misplaced was the one head stud nut in the bellhousing.... I also couldn't believe Adam sniped that with a magnet.

The blue stuff is actually plastic wrap used to protect floors. I saw a few shops were using the stuff and after a good deal of homework, I tracked down what it was. The wrap is thick enough to avoid marring but also sticks well to avoid movement (to cause a scratch). I wouldn't recommend leaving it on for more than a couple days or on a freshly painted surface.

https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|

|