|

|

12-14-2021, 07:22 PM

12-14-2021, 07:22 PM

|

#426

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

That spring held in by the pin is the one you want to look at.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

12-14-2021, 09:26 PM

12-14-2021, 09:26 PM

|

#427

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

yup, thanks Matt. Makes sense!

I did a little research today and brought the pump to work where I disassembled it..took that roll-pin out and the spring out. I couldn't verify that the spring was stuck or not, but I did learn how it all worked when I called Melling just after I took it apart. The internal pressure relief valve slides open to relieve pressure (controlled by the spring). If the valve or spring is stuck, it would cause high pressure as it is unable to bypass the excess fluid. According to melling, the spring in this current pump is a 58 psi spring. Which makes sense, because i was getting 60 psi (on my stock camaro dashboard's oil pressure gauge) for many months. And then all of a sudden after racing at island one day LAST October, it went to 80ish psi and lived around there ever since. Melling also said,t hat 80 isn't dangerous back then when I called them, and they said the same exact thing to me today. During our chat today, they did agree that I should repair or replace the pump. Melling then told me that they would recomend a better version of the pump, one with better gears, a chromoly shaft, a more robust "neck", and a (blue) spring installed that is pre-set to 70 psi. It also comes with another 58 psi spring, but he said the 70 psi would be best for me due to how I use the car and the rpms I rev to.

-The pump they recommended to me is the Melling Select # 10550ST. ( link contains a video)

https://www.summitracing.com/parts/m...gaAh9SEALw_wcB

Looks like I would have to buy a pickup tube though? And then weld it on to the pump? Am I correct ?

I then called the Engine builder (Pat at Nyes Racing Engines) and he agreed that this pump would be great, along with the blue 70psi spring. We also chatted about rear main seals and the oil pan gasket failure as well as what gaskets to use for the rebuild.

FelPro Rear main seal:

https://www.summitracing.com/parts/f...8aAlUuEALw_wcB

OR,

I could buy the bottom end block full gasket set:

https://www.summitracing.com/parts/fel-cs77332

but this comes with the 4 piece cork gasket set for the oil pan. I'm thinking of using the 1 piece synthetic oil pan gasket.

__________________

1987 IROC-Z - modified

|

|

|

12-15-2021, 10:06 AM

12-15-2021, 10:06 AM

|

#428

|

Join Date: Oct 2008

Posts: 586

|

Exhaust

ARH in NY or Ultimate Headers. Since you want to save weight, look at TiCon.  Talked to all three at PRI. YMind you these are not low cost leaders , but for those who want the goods.

Ticon will most likely be a system you fab or build your headers out of 'legos' & send that model to them to fab.

|

|

|

12-15-2021, 07:51 PM

12-15-2021, 07:51 PM

|

#429

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

awesome, thanks Larry. I will look them up in the coming weeks. Sadly, the exhaust project will have to be on a limited budget, but it does need to be done as my current exhaust is no longer suitable. That does seem cool of how you would mock-up your headers and then they would build them.

__________________

1987 IROC-Z - modified

|

|

|

12-18-2021, 11:16 PM

12-18-2021, 11:16 PM

|

#430

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

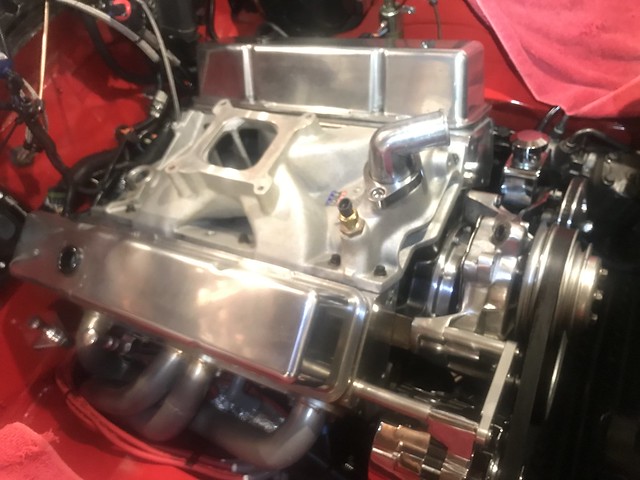

The parts arrived Friday and I got them installed. The new melling "shark tooth" style oil pump has many benefits I listed above, and it also is said to do away with any "pulsing" that the straight-cut gears cause and oil pressure results in a fluttering gauge. So since I will be adding a secondary oil pressure gauge (on the A-pillar), I should have a rock solid and accurate oil pressure reading from both gauges. I kept the 70 psi spring in the pump, but the pump kit came with the 58 psi spring if I ever want to change it out. The oil screen/pickup did not come with the pump, so I measured and did my research to get the right depth one. I welded the pickup tube to the pump also. I went with the FelPro 1piece gasket with the thick groove at the timing cover. It came with new bolts also. I also installed a new Felpro 2900 rear main seal, making sure to offset it 3/8" from the block and dabbed a touch of permatex "right stuff" 90 minute gasket maker on the ends of the RMS that meet eachother. I also used this same permatex at the front and back corners of the block before installing the felpro oil pan gasket. Did some degreasing of the engine while it was on the engine stand, and installed a new oil filter as well. Took a few hours and opened up all the engine bay wire loom to reconfigure the wiring a bit better. Cut out some unnecessary stuff, combined grounds, used label maker on important wires, and relocated some wiring to go inside the cabin to a separate fuse block I mounted under the passenger dashboard area. Tucked everything away in split loom and temporarily routed it in place.

With everything on the engine buttoned up, I rolled it over to the chain hoist and got the hook on the lift plate. My dad and a hot rodding neighbor came by and we dropped the engine in, landing it in place like a perfect dream on the first shot. Two motor mount bolts slid in without any persuasion. Super simple and effortless. Got the chain hoist and pipe-jacks out of the way just in time to go meet-up with a fella who bought my old Nitto 555 tires from me (see ad in classifieds). He has some turbocharged volvo drift car and was excited to have a set of tires to fry, so its cool that my old tires will be laid to rest in a long smokey drift burnout instead of just discarded to the trash. Anyways, with only a little time left in the afternoon today, I popped in the hyperspark distributor, bolted on the nitrous plate and its wiring/plumbing, and also installed the sniper throttle body and half of it's wiring. I have a few hours tomorrow afternoon to try to get the transmission, converter, driveshaft, headers, radiator, wiring, plumbing, fluids, etc taken care of.

Sidenote, next month I am removing the main crank pulley and the water pump pulley and getting them professionally finished. Had zero luck finding a local NJ chrome shop (called 11 potential places and struck out) and I am fearful of shipping them because in recent months USPS and UPS has completely lost 4 of my outgoing packages. But there are a few local places that do similar shiny-silvery coatings, so I am going to try that. Also opting for the less flashy non-chrome finish on these pulleys because I don't want TOO much attention to be drawn to a stamped steel pulley, but they do look very bad with my poorly done "chrome" aerosol paint job that is 2 years old and flaking off. Was quoted about $25-$30 per pulley so thats not a bad deal.

__________________

1987 IROC-Z - modified

|

|

|

12-19-2021, 12:20 PM

12-19-2021, 12:20 PM

|

#431

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Damn you work fast! Looks good from here as always.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

12-26-2021, 10:35 PM

12-26-2021, 10:35 PM

|

#432

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

It was a busy week for everything except the car, but I finally had a few hours on Friday and Today to get stuff accomplished. Got the converter, transmission, driveshaft, (old) headers, radiator, fans, electronics, nitrous, distributor, sniper efi, fuel lines, starter, new Lokar tv cable, trans fluid lines, etc etc installed. Poured in some fluids too. Cranked the engine over without fuel just to make sure everything sounded normal. Since it did, I put fuel to it and the damn thing fired right up. Oil pressure was there right away and not "off the charts" like I was used to seeing. My dash gauge is probably not super accurate, and the 20w-50 oil was cold/thick so the dashboard gauge displayed higher than the 70 psi that the 70 psi spring in the pump should produce.

(Two gallons of the evans was the stuff I removed/saved from the cooling system a few weeks ago, so I only needed to buy one new gallon...and turns out, I only needed about 1pint from it anyways!)

Later on, hours AFTER I put in the 20w-50 VR1 and ran the car for a bit my buddy suggested I put in some lighter weight oil for the cold winter ahead. So I drained the fresh VR1 and put in some Valvoline 10w30 because I do plan on running the car occasionally and doing some short test drives during the cold winter anyways. I saved the brand new VR1 and it will go back in the engine around March. Maybe I am overthinking it, but the brand new oil pump and gaskets/seals might get worked-in better without having to pump 70 psi of thick 20w-50 oil during cold weather cold-starts.

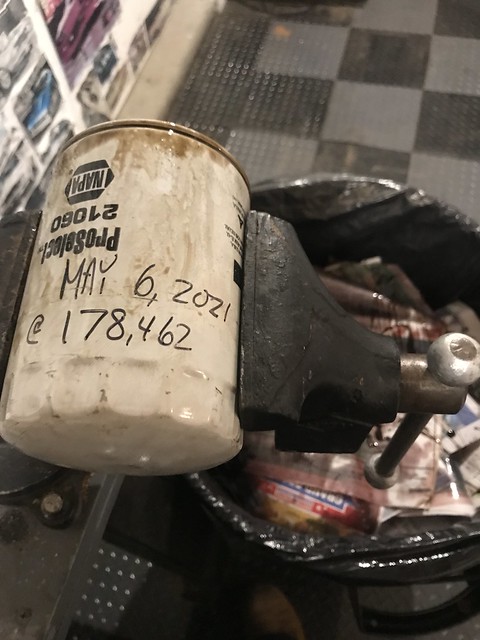

I cut open the old oil filter (May 2021) and the transmission filter (February 2021) like I usually do, and everything looked very good. Just a little bit of metallic sludge on the magnet of the transmission filter, but the filter element was clean. Same for the engine oil filter, very clean.

Oil:

Trans:

I have a few more button-up and clean-up things to do tomorrow since I am off from work, but afterwards I plan to take the car on a road test. If everything is in order, I can start moving on to the research/purchase of some of the other winter projects.

- Long tube headers with a full exhaust

- Set of gauges in the A-pillar (oil pressure, fuel pressure and secondary Oxygen sensor)

- fuel tank access door in the trunk

- getting water pump pulley and crank balancer pulley refinished

- replacing oem steel transmission fluid lines with CopperNickle 5/16" lines

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 12-26-2021 at 10:40 PM.

|

|

|

12-27-2021, 08:58 PM

12-27-2021, 08:58 PM

|

#433

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

Got stuff on the top of the engine taken care of and fired up the engine again. Took it around the neighborhood to get some heat in the engine so that I could check/adjust the timing. When I pulled back in the driveway, I was stunned to see oil dripping at the back of the engine. However, it was not from the rear main seal or oil pan gasket. It was also not from the head gasket area or valve covers. At first I thought it was the little pipe-plug at the back of the block by the distributor, but sadly it looks like the rear china wall has a leak at the intake manifold gasket. This is a new leak and for sure 100% was not there when I was using the car during the spring or summer. My buddy told me that sometimes (not always) the intake manifold gasket may develop a break in the sealing surfaces when using the carburetor style engine lift plate that I used, because the weight is hanging on the manifold bolts with the gasket in between. . This makes total sense, and I wish I had thought of this weeks ago. BUMMER! Looks like I will be ordering a replacement intake manifold gasket, and pulling apart the top end again.

I just do not want any leaks, and even though it is a minor oil leak, it is not going to get better on its own, so I am going to take care of it next. After setting the timing and topping off fluids, I took the car for a longer drive, and it was ripping, just blowing off the cold tires on the cold road! Good fun. Oh, and oil pressure is now right about 70psi according to the dashboard gauge, so I am super happy. Also, no idea what is with my trans temp gauge, its pegged at max, so possibly has a short or stuck needle, I'll need to get that fixed next time I am under the dashboard.

__________________

1987 IROC-Z - modified

|

|

|

12-28-2021, 09:14 PM

12-28-2021, 09:14 PM

|

#434

|

Join Date: Sep 2010

Location: Hackettstown, NJ

Posts: 165

|

Nice update Dave. Sucks about the oil leak. Have a safe Happy New Year.

__________________

57 Chevy - 210 - 355 SBC-Powerglide-10 Bolt 3:73 Gears - 12.78 best et - 104.78 MPH-street driven

80 Firebird-350 SBC-Turbo 350-10 Bolt 3:42 Gear - 13.69 best et @ 97.52 MPH

96 Buick Roadmaster wagon LT-1 - (DD) for sale

2023 Equinox - wifey's car

22-Ford Maverick-FWD Eco

|

|

|

01-02-2022, 09:21 PM

01-02-2022, 09:21 PM

|

#435

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

yea, slight bummer about the intake leak, but nothing too terrible int he grand scheme of things. Pulled everything apart one day last week and ordered a set of Edelbrock gaskets (same that were on it). Once they were delivered a few days later, I used some Permatex 90 minute rtv and got everything installed. Let it cure and fired up the car. No leaks, all set. Good stuff

I have been doing a whole lot of research on the exhaust components, mostly on thirdgen.org where I have a longgg thread discussing this topic. link: https://www.thirdgen.org/forums/exha...ons-700-a.html There were a few options, but my budget is limited for this exhaust project so some of the high dollar custom built headers were not a realistic option. I knew I needed a 1.75" diameter primary tube and I wanted a long tube setup that maintained good ground clearance. The hooker super comps and dougs hang a little low,and my car is already low. A buddy of mine was going to give me his hooker super comps, but many of hte primaries were bashed in and would need a ton of work, plus some type of ceramic heat coating. They were my optionB. Option A, was a set of those chineese ebay headers that 3rd gen and even 4th gen guys have had pretty good success with. At $212 with free shipping I am willing to give them a try.

link:

https://www.ebay.com/itm/30361071372...151000b2p00004

These tuck up well and I have seen plenty of photos that show great clearance. Unfortunately they have a collector that goes from 3" and necks-down to 2.5". So my plan is to simply cut off the necked-down part and weld on my own flange or v-band at that point.

very long thread that has been going on for many years regarding these ebay longtubes:

https://www.thirdgen.org/forums/exha...gtubes-10.html

I am also pretty much settled on buying a 4" mufflex "cat back" setup. I have no desire to fight a set of dual 2.5" exhaust pipes to the back of the car. Not interested. The mufflex 4" will be tight in some key areas, but I think i ca make it work with much less headache than a dual pipe setup. I will have to decide on which muffler I want to go with, but I think i am going to skip a spintech, and probably go with the magnaflor or flowmaster. I do not care about having dual tailpipes, so it will be a single 4" in and 4" out muffler with a turndown under the bumper.

link: https://mufflex-performance.com/1982...lowmaster.html

I called Denny at mufflex and he said there is no wiggle room on the price, even if I drove down to pick it up. He did say that prices are going up quite a bit for 2022, but he could lock me in at the previous listed price.

What all this means, is that I will be building my own collectors and y-pipe which will either incorporate a single 4" electric exhaust cut out or two 3" cut outs. I already have one 3" cutout, so if space allows I would do two 3" cutouts right after the collectors and before the merge. if not, I'll sell the 3" cutout that I have and buy a 4" instead. I've seen some fbody guys get creative and cut out pockets of the factory inner subframe rails. I might also do this too, and the car is solid-enough to do this because of subframe connectors and 6 point roll bar. I might have to build my own trans crossmember, and also modify the S&W relocated torque arm mount (which doubles as a driveshaft loop). So I have some work cut out for me this month, but I am ok with that.

I will end up selling the dynodons headers and y-pipe after my exhaust project is complete, so if anyone is interested, shoot me a PM. They are 1.75" primaries but a short/mid length header. The collectors are 2.5" and a ball-cup style mating surface. The y-pipe is in great shape and was cut/welded to gain extra ground clearance. I have had these on the car since about 2007, and they have served me very well. Probably will be for sale mid February.

__________________

1987 IROC-Z - modified

|

|

|

01-03-2022, 04:43 PM

01-03-2022, 04:43 PM

|

#436

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

The sewer pipe will certainly flow as needed and I'm curious if your clearance over the axle will be better vs the 4th gens. Its silly tight on mine.

Nice work on the intake fix. You certainly don't waste any time.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

01-08-2022, 10:10 PM

01-08-2022, 10:10 PM

|

#437

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

Drove the car around the neighborhood one last time on Thursday night with the old exhaust system. Then I removed the water pump pulley and main crank pulley as well as the rear diff cover. I dropped off the two pulleys and the 12-bolt aluminum diff cover at a local powdercoating place in Rockaway yesterday. They will get sandbalsted and powdercoated in a "like chrome" coating for $120.

So,

I broke the exhaust system down into thirds, so I knew how I was going to handle each segment.

1st third: Headers only (ebay stainless steel kit)

2nd third: header collectors, cutouts, and 3"-4" merge pipe (to be determined)

3rd third: main pipe, over axle pipe, muffler, and tailpipe (mufflex 4" system with magnaflow muffler)

My headers arrived in the mail on Thursday. the box was beat up, but fortunately all of the pipes inside the box were in good shape. I bought this $212 ebay kit knowing full well that I would not be using the 2.5" collector pipes or the 2.5"into3" merge Ypipe. After discussion with the guys at Thirdgen.Org, I determined it would be perfectly ok to cut-off the necked-down 2.5" diameter section of the header collector and leave it at 3" diameter. The flanges are not warped at all and are thick, The welding on the inside of the primary pipes is pretty decent too surprisingly. There is 1 bung/port for an oxygen sensor, but I had planned on welding in my own instead so this port will stay capped closed.

Yesterday, despite the morning snow storm, I drove down to Mufflex in Trenton, and purchased their single 4" system for $702 out the door. I decided ont he straight through design of the magnaflow muffler, taking into account everything you guys said in these past two thread pages. I'm sure some of you had the same reaction to seeing a 4" diameter exhaust, and man this pipe diameter is big! It is an aluminized system, with the stainless steel magnaflow muffler. It came with a bunch of band-clamps, hangers, and hardware. I spent a good amount of time chatting with Denny at mufflex and he gave me a heads up that this exhaust might cause my AFR to lean out a bit; so I should beware that I might have to add some fuel into my fuel tables. Good to know! Any of you guys have similar experience with a free flowing exhaust making the afr lean out a little bit?

Got everything unpacked this morning and laid it out in the driveway, putting my old exhaust system next to it. I measured the lengths of the primary header pipes on both the new ebay headers as well as the old DynoDon's headers. I started drawing out what my middle section might be comprised of, based on our discussions above and some photos that others have posted on previous threads on TGO. I knew that it really would be better for my visualization if I bolted stuff on the car, so after lunch I started bolting stuff on (see next post).

Below are just a few photos showing the similarities/differences of the dynodons vs the ebay headers.

.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 01-08-2022 at 10:12 PM.

|

|

|

01-08-2022, 10:25 PM

01-08-2022, 10:25 PM

|

#438

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

...continued

flanges/ports:

Inside Ebay collector:

Inside DynoDons collector

Magnaflow muffler:

I got everything picked up off the driveway and brought the new components into the garage, where I turned on the heat and put on some tunes. I cut off the necked-down section of the header's collectors and I will true up the cut before I weld a V-band onto it. Then, I started with the passenger side header, and I predicted it would be easy, but I did not expect it to be that freakin easy. I probably didn't need to even take out the spark plugs, plug wires, or undo the other wiring, but I do think that I would have needed to remove the starter...which i had already done. This header slipped right in like a dream. I was laughing in astonishment as it was happening! Then I went to the drivers side, where I had also already removed the plugs and wires, oil pressure sensor, as well as the Walter-racecraft steering shaft. It went right in just as easy as the passenger side! The only cursing I was doing in my garage was to the tune of "holy s***, I can't f****** believe this is going this easy! Underneath, I was elated to find out that these headers truly do not hang all that low and at the bottom of them, they are still about 1" above the bottom of the oil pan. I only installed them with 3 header bolts per side, but they are snugged up and I used the old gaskets for now...knowing that I will be taking them out for welding. Oh, and the protective covering on them is Glad peel-n-stick kitchen wrap, just to prevent my hands or tools from scuffing them up. I will be putting a T-fitting for my oil pressure sending unit,and I am going to be adding a secondary oil pressure gauge to the car, up on the A-pillar in February. As for the oem steel transmission fluid lines, I have always fought with those and I am done. I am going to buy a few linear feet of 5/16" copper-nickel tubing and some fittings so that I can route the lines in a less obtrusive manner under the car. I will also be getting some DEI heat shielding to slip over the trans cooler lines too.

I had the headers in so quick that I just kept on moving and decided to mock-up the mufflex system too. I wanted to see where the "front" of the main pipe would be so that I could start to figure out the middle #2 section. The mufflex pipes are very big but I was super impressed by the fitment and placement of the bends. Looking under the car before installing them, I said, man this wont work. But once I put em in, I was like wow, this is niiiiiiiice. .

So that leads me to the complex project of what to do in the middle. I absorbed everyone's input on my exhaust thread on TGO, as well as other technical research I did across the internet, and I am hoping I can pull off my plan here. I am fully aware that this will require me either building a new transmission mount/crossmember and also notching out some portions of the oem frame to create pockets, and I am ok with doing that. I also will need to cut and redo parts of the S&W crossmember that holds the torque arm and doubles as a driveshaft safety loop. However, if I can do that properly, I think I can have a long 3" collector off of each header pipe and then bring this to a 3" y pipe with a cutout on each side. These dual 3" y-pipes can then join into a 4" flowmaster Y (part number Y300400) which can then meet up with the mufflex system. I did a rough 2-Dimensional sketch of this on cardboard.

Anyone have any thoughts on why this would NOT be a good idea, or if it is genuinely a pretty good way of building things, I would like to start ordering some parts tomorrow night. I would need a second DMH cutout, along with its corresponding Y-pipe ($199 total). The flowmaster 3"-4" Y pipe is like $60. I am considering some of that fiberglass heat-wrap on this whole Y-pipe section. I am fully aware that heat wrapping it can trap moisture and rust the pipes, but it might be beneficial to keep the heat inside the exhaust pipes instead of radiating out of the pipe's exterior and baking the transmission, underside of the cabin, and nearby lines/electronics. Thoughts? If I do decide on some heat wrapping, it might make sense for me to use some sections of my old hooker 3" exhaust system to use for straights, curves, and pie cuts when building each collector. I already have the pipes and it would save some money on buying new sections of 3" tubes to cutup and weld together.

So, that is where I am at for now. Got wayy more done today than I had planned on, so thats good, but I know I will have my hands full in the weeks ahead as I get the rest worked out.

__________________

1987 IROC-Z - modified

|

|

|

01-09-2022, 07:50 AM

01-09-2022, 07:50 AM

|

#439

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

My car was tuned with the mufflex so I can't comment on the leaning out comment/question. Nice to see someone has good luck with fitment of new parts. Very jealous.

As for the exhaust system merge, that's essentially how mine is. I would personally ditch the cutouts at this point. The magnaflow muffler is not going to do much to quiet her down and you have plenty of flow happening here. Just a thought.

Oh and for wrapping things, I'd recommend getting them coated. It will be more expensive but a couple folks have commented that once you get some oil on them, it never really burns off completely. Granted you've fixed your leaks but we know how things go. I'd leave it bare or get it coated.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

Last edited by Blackbirdws6; 01-09-2022 at 07:52 AM.

|

|

|

01-09-2022, 09:12 PM

01-09-2022, 09:12 PM

|

#440

|

|

Admin.

Join Date: Aug 2005

Location: Hamilton, NJ

Posts: 20,153

|

Quote:

|

Yesterday, despite the morning snow storm, I drove down to Mufflex in Trenton, and purchased their single 4" system for $702 out the door.

|

A mile away from us and didn't even stop to say hello to BTK and me. I see how it is.

Its about time you got a real exhaust. Throw your cutouts on the shelf and move on. Resist your urge to complicate making ice.

Anecdotal observation, but when I put the new headers & exhaust on the Z can ran better and did lean out a bit. That was going from ****ed up old hooker super comps & cobbled 2 1/2" mess to 1 3/4 ARH headers & dual 3" pipes.

__________________

Vent Windows Forever!

The looser the waistband, the deeper the quicksand. Or so I have read.

Feather-light suspension, Konis just couldn't hold. I'm so glad I took a look inside your showroom doors.

Hey everybody, it's good to have you on the Baba-too-da-ba-too-ba-ba-buh-doo-ga-ga-bop-a-dop

|

|

|

01-10-2022, 07:27 PM

01-10-2022, 07:27 PM

|

#441

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Another vote for ditching cutouts.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

01-17-2022, 09:27 PM

01-17-2022, 09:27 PM

|

#442

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

Thanks guys, good stuff. Should have stopped by to see you guys down south, didn't think of it. Decided on not installing cutouts and I am thankful for all input on the topic too. IT will save money, cut down on fab work, save space, and whatnot.

Not too much of a progress update recently, got busy with some other things.

I did get some time to cut out some sections of the oem frame-rails on the passenger side of the transmission tunnel. There is no other way to truly tuck a 3" collector along the area of the 700r4 transmission and the design of the oem inner "frame-rail". stick shift guys have more space and those with smaller automatic transmissions, but not me with the 700r. But, No need to be alarmed, as I immediately used very beefy angle iron to reinforce the remaining frame rail and welded this angle iron to the floor-pan sheet-metal. I also welded a reinforcing flat plate in place on top of hte angle iron too, so it is strong and all stitched together. Once the final placement/fitment of the 3" collector pipe is in place, I am probably going to add a type of triangle brace into the framerail also. I still have to wait to do all that until I build a full transmission cross-member from scratch, so I have some work cut out for myself. No photo updates for now, and taking that much metal out of the frame was a bit scary, but I assure you guys that I welded a lot of reinforcement to make up for the removed frame. keep in mind that I have the subframe connectors coupled to extra bars that go to the rocker area and another section where a sandwich-plate bolts through the floor...along with a full 6-point roll bar. The reason I did all this, is simply to retain ground clearance with the entire exhaust. There was no other way to do this without notching/removing the section frame. I am certainly not the first person to do this, but it is a path less traveled.

after Speaking with some knowledgeable people, I decided to get some sections of that "flexible" 3" pipe...(which is still surprisingly rigid!). This is simply to allow an element of FLEX in the entirety of the exhaust pipes, while the engine torques and twists, and the car travels along the road/tracks. Lots of stories about cracking welds, exhaust leaks, and stuff because of rigidity in the entirety of the pipes, and this has been the culprit of a lot of people having crazy efi/tune issues; even running way rich via ecu fuel correction and killing oxygen sensors. While the flex pipes are unsightly, I think that these flex sections will be beneficial. I made sure I got the kind that are braided on the outside, but fully lined inside the pipe.. not the cheap-o kind. https://www.summitracing.com/parts/sum-643030. These will go after my o2 sensor, but before the two 3" pipes join to the 4" mufflex exhaust. (using hat flowmaster scavenger 3"to4" merge)

Regarding the oxygen sensors, I was never a fan of where the sensor bung was in those Dyno Dons headers. I wish the bung was a little further back in the collector so it got a "blend" of the 4 cylinders, instead of just the two cylinders nearby it. (Its not visible in my above photos due to the angle I took the picture at, but its just real close to the edge of the primary pipes in the small merge) Anyways, this always seemed to cause a bouncy/erratic AFR reading... that probably was just due to the firing order and exhaust pulses. Along with the holley sniper's wideband oxygen sensor, I use the highly recommended HBX-1 oxygen sensor extender, which is a MUST do for nitrous.

-- my question for you guys is about oxygen sensor placement. I've read a bunch about it, and know that it has to be upright or at the very least, angled so that it can't retain moisture. We don't need to discuss that.... My question is more about how far back from the collector it can be? Since I will not have exhaust cutouts, there will be no chance for ambient air to give a false-reading through the backside of the exhaust system. It is very crowded under these cars, and I want the sensor in a safe spot, where it can get accurate oxygen count readings, and the closest I can get to weld a bung onto a collector pipe is 17-18" from the very end of the ending edge of the primary pipes. * This is exactly where the oem transmission mount/crossmeber is... and is the best chance I have with enough real-estate to install the bung/sensor. Is this too far back? One oxygen sensor will run the holley sniper efi, and I plan on adding in a second o2 sensor so I can finally have some type of reading of what the passenger side of then engine is actually doing. This will go to a gauge in the A-pillar, because the sniper can ONLY use one o2 sensor for its calculations... but I can compare the left bank with right bank in my brain and probably have enough length in the o2 wires to switch them side to side for comparison.

__________________

1987 IROC-Z - modified

|

|

|

01-18-2022, 07:25 AM

01-18-2022, 07:25 AM

|

#443

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

What does the holley manual say for 02 sensor location, that is what I would go off of.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

01-18-2022, 01:23 PM

01-18-2022, 01:23 PM

|

#444

|

Join Date: Nov 2007

Location: Jackson, NJ

Posts: 1,725

|

You'll be fine, my truck and the C6 put the O2 sensors further back and there are obviously no issues.

__________________

1983 camaro- Scrap

1988 camaro- Also scrap

'05 Silverado- You guessed it, scrap

1988 TRX 250R- Ported w/ high compression on 110 octane- Out 60' your LT1

Jersey Shore Street Car Takeover (JSSCT) Founder

Quote:

Originally Posted by LS1ow

and once i get PHB, what do i ajust it too?

|

Quote:

Originally Posted by Jersey Mike

Seven.

|

|

|

|

01-18-2022, 08:49 PM

01-18-2022, 08:49 PM

|

#445

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

Good to know, thanks fellas.

The manual just had the basic generic info that I had expected. Even the official holley efi youtube videos were pretty generic about it, saying not to let the sensor get too close to the exhaust systems exit, and also mount it upward to avoid fluids puddling in it.

-I did get some good info over on the holley efi forums on a thread I typed up last night. Most importantly, that if I move the sensor more downstream, I might have to go in and adjust the sensors "advanced control" . Interesting to know. Apparently, even though the sensor sends immediate data to the ecu, that data is "old" because it has taken "some time" to reach the sensor after actually combusting in the cylinder.

here is a link to the thread:

https://forums.holley.com/showthread...-oxygen-sensor

See below for the photos of my new ebay headers and the dyno dons headers and you can get a sense of why I think that the sensor location isn't getting a true reading of all 4 cylinders... its just too close to the primaries.

New ebay headers with o2 bung location:

Old dyno-dons headers and bung:

see what I mean about how I just don't believe that a sensor located there could get accurate readings on all 4 of the primary ends? Maybe the two of them nearby the bung, but not the far two.

__________________

1987 IROC-Z - modified

|

|

|

01-21-2022, 08:13 PM

01-21-2022, 08:13 PM

|

#446

|

Join Date: Sep 2008

Location: Hackettstown, NJ

Posts: 1,649

|

Just don't run the sensor too far back. It needs heat to work, and too far away it'll get cold and 'lazy' in it's response.

__________________

1998 Z-28 - SLP lid - Ported TB - LS6 Intake - Dynatech SS headers/Catted Y - Magnaflow Exh - 3.42 - Yank SS3600 - UMI weld-in subframe connectors, Adj LCA, Adj PHB, Q1A TA - Bolt-in Relocation Brackets - Strano springs - Koni shocks - 17" C6Z06 wheels - 326HP/335ft-lbs - 12.35 @ 110.41

Quote:

Originally Posted by Blackbirdws6

I can appreciate a dream but this person needed some real friends.

|

|

|

|

01-22-2022, 08:56 PM

01-22-2022, 08:56 PM

|

#447

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

yea, I agree with you. I am going to try to get it to the closest accessible spot in a collector, but the massive 700r4 and trans tunnel sheetmetal prevent me from a good amount of possible mounting area. The closest spot I can feasibly get a sensor to live would be back by the tailshaft....thats pretty far back. Since the sensor has to be facing downward/vertical I just dont have any upward clearance areas until about the tailshaft. I'll see what I can do, still fabbing up the transmission crossmember. It has become quite the massive project.

__________________

1987 IROC-Z - modified

|

|

|

01-25-2022, 08:58 PM

01-25-2022, 08:58 PM

|

#448

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

A good bit of progress, but nothing specifically exhaust related.

I think I mentioned above that I was going to have to get creative with routing the exhaust because I am UNWILLING to let my exhaust be the lowest component of the vehicle. I did not want the hassle of banging exhaust pipes closed-flat on a speed bump or pothole, or having welds crack, and throwing off oxygen sensor readings or the whole tune. I did not want to have to regularly repair exhaust damage or deal with the leaks, so I did what I had to do and made sacrifices to the oem sheetmetal/frame-rail under the car...specifically the passenger side. The stick-shift guys have it made when it comes to clearance between the transmission housing and the trans tunnel, but not for me with the bif 700r4 trans. Almost everyone who has a 700r and wants a 3" collectors settles on having them hang really low and passing almost "under the framerails" completely. Not something I was going to allow, I was determined to find a better way. So I took a different approach and cut out half of the "box' that made up the passenger side inner frame-rail along the trans tunnel. It is surprisingly thin metal just stamped, folded and spot welded... but it worked just fine for the stock chassis indeed. I kept the outside "rail" and then welded a series of 2"x2" pieces of angle iron to this edge and to the underside of the floor to retain rigidity in this area of the car. I then cut some flat plates of metal and lapped them over the angle iron and welded them to the angle iron and the floor sheetmetal where the oem frame had met the trans tunnel. My subframe connectors also connect to this part of the oem frame, and I boxed in the open area at the front which is near the firewall. My welds were decent, but the damn rubber based undercoating kept giving me problems despite me doing my best to scrape it all off. I used a heat-rated seam sealer on the welds, gaps, and any open areas, and while the seam sealer will serve a nice "sealing" purpose, it made the underside look messy and unsmooth. Once the seam sealer was cured, I painted over everything with VHT high heat engine enamel satin black paint. Not everyone might like my approach to this, but its my car and what I thought was the solution that would give me the most options of collector clearance. It is structurally sound, for sure.

-please remember, this cut out section of frame was reinforced, but I didn't get to take a picture of it before seam-sealer and paint.sorry

I did a whole lot of research on crossmembers, both on fbody sites, drag websites, unibody car stuff, etc. I saw some interesting stuff, and I knew that to get the fitment I was looking for, I would have to build one. The hooker trans crossmember and some others are ok, but each left a lot to be desired, and I knew I would regret buying something that didn't check all the boxes I required.....plus NONE would fit with the way I cut out half the passenger side's framerail.

So I was on my own. I came up with a cardboard design using arches, but it didn't seem feasible. I then designed one out of heavy card-stock and used the strength properties that come with triangles and angles to create a mock up. I got some scrap steel from work, some from home depot (which I didn't use and returned) and some from a local welding place for $20. In the end I used the 1.5" angle iron for the outer mounts, the 3" x 3/16" flat stock for the "arms" and some "gusset supports" and then the 3"x1" rectangle tube for the base. The trans tunnel of these cars is filled with weird angles and interesting geometry, which left my home-built trans mount not aesthetically symmetrical, but it is super strong. As I mentioned a week ago, I have always wanted to do away with the threaded-inserts that the factory used for mounting the trans crossmember. Three out of the four were previously stripped out and I had re-tapped them with a bigger thread size, but I was always unhappy about it. So, I bought some huge 1/2" diameter grade-8 zinc coated bolts and welded them to a 1/8" plate that lives on each side of the sheetmetal floor in the driver's compartment. Drilled holes through the floor, the oem subframe rails (and my passenger side home made angle-iron rail) and used three bolts per side to locate and hold my transmission crossmember up. Also, not pictured (but already drilled and mocked up) will be several long 3/8" bolts that go horizontally through the crossmember's outer mounts, through the car's frame rails, and through the mounting pad of the S&W subframe connector too. These will secure the trans mount laterally. This thing is not going anywhere, and it is robust. I will have to weigh it compared to the oem unit, but it had to be done with heavy duty strength in mind.

this is a view looking backwards to teh rear of the car along the driver's side, obviously fuel lines and all that are just loosely pulled aside still

looking backwards on the car along passenger side trans tunnel. don't mind the sloppy seam sealer.

looking up from the passenger side :

If my measurements are correct, the way I built the "arches" in the trans crossmember, it will allow me to bring up my 3" collector pipes about 1 5/8" higher than where the would have lived if I let them hang under the frame and oem trans crossmember. They will not be the lowest item on the car. So that's exactly what I was gong for, primarily to save ground clearance.

- this all took a ton of work, and I hope it all works out. Seems ultra strong here sitting in the car, but the true test will be when the car is driving/racing around. I still need to cut/modify the crossmember that holds the torque arm and rebuild some type of driveshaft safety loop, so that will be soon. However, I am now getting to the point where I can actually start to work on the exhaust components. First will be putting V-bands on the header's and then working out pie cuts, pipe, and flex-pipe to get to the flowmaster 3"to4" merge collector.

On another note, I did get the pulleys and diff cover back form the powdercoating guy, with tip, just a tad over $100. Installed the diff cover but have yet to install the pulleys. the diff cover comes from moser with a slightly textured aluminum finish, so the powsercoating is not glass smooth, but it turned out great. I had him mask off and keep the Moser logo on there too.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 01-25-2022 at 09:22 PM.

|

|

|

01-30-2022, 08:32 PM

01-30-2022, 08:32 PM

|

#449

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

Having the transmission cross-member and mount done was a big cross-off and it allowed me to move on to modifying the cross-member that spans the gap between the right/left sub-frame connector, and it also doubles as part of the driveshaft safety loop, but most importantly, it is the front mount for my adjustable torque arm. The bottom part of it has been the lowest point of my undercarriage for 10+ years, and I knew I could not run the exhaust any lower than this point all along the underside of the whole car. The 4" pipe barely fit above it, but I knew the exhaust would need some movement/flex as the car drives along, so I made the choice to cut out a section of the cross-bar and put in a notch. I also needed to re-bend the 3/16" steel that is the driveshaft safety loop, and I cut of the one mounting tab for it and moved it a few inches outboard on the cross-bar. The notch in the bar will be right where the 3"to4" flowmaster merge will be and it should have good clearance when the exhaust is finally mounted on metal hangers add anchored good. However, just in case, I might want to put some type of "heat safe" padding or isolator between the merge collector and that flat piece on the cross-bar. What kind of material would work for that?

here you can see the six 1/2" bolts coming from above , and also the 3/8" bolts that go horizontally from the frame/subframe through the trans crossmember side mounts

I temporarily positioned the mufflex system, but my next task will be welding the v-band flanges onto the ends of the longtube headers. I pulled out the headers today, so maybe after work tomorrow I can get the flanges on them. Once that is done, I can install the headers for good, as well as install the starter, run new copper-nickle trans fluid lines, and install the oil pressure sending unit as well.

Then it will be onto a new challenge for me, making the pie-cuts and lengths of pipe that will run from each header to the flowmaster 3"to4" collector. This is where I will have a section of straight 3" diameter pipe that I plan on welding in some oxygen sensor bungs. I will also be using those flex-pipes, but I am going to put them downstream of the o2 sensor, (in front of the merge pipe), just in case they have any small leaks.. it hopefully wont get screwey with the o2 sensors.

Drivers side idea

Pass side idea

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 01-30-2022 at 08:50 PM.

|

|

|

01-30-2022, 09:07 PM

01-30-2022, 09:07 PM

|

#450

|

Join Date: Oct 2008

Posts: 586

|

Pie cuts are a great way to practice TIG welding. They can be frustrating yet rewarding once completed.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|

|