|

|

01-31-2022, 09:20 PM

01-31-2022, 09:20 PM

|

#451

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

very true Larry, I am excited to get more tig torch practice in!

Today after work, I did just that. I tig welded one flange of the v-bands to each header's exit. I used my old Miller EconoTig, which is from 1994, so it does not have all sorts of settings like new welders do. Its pretty basic, just a few knobs and a foot pedal, but it was up to the task.

Today was the first day i welded on an actual stainless steel part, as opposed to scrap stainless pieces that I collected from work. Anyways, I used 1/16" 880 filler rod and followed the advice of the internet welders.. but working in small sections in order to avoid warping the flange. I wish I had a nice big welding bench, as I had to stand up and work in contorted angles to get proper torch angle on the round pipes, but all in all, I think it turned out pretty decent.

__________________

1987 IROC-Z - modified

|

|

|

02-01-2022, 08:26 AM

02-01-2022, 08:26 AM

|

#452

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,342

|

No shame in that, nice work!

|

|

|

02-01-2022, 09:24 AM

02-01-2022, 09:24 AM

|

#453

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Looks good from here!

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

02-01-2022, 10:48 AM

02-01-2022, 10:48 AM

|

#454

|

Join Date: Nov 2007

Location: Jackson, NJ

Posts: 1,725

|

What is 880 rod?

I use 308 filler on the 304 stainless parts I weld

__________________

1983 camaro- Scrap

1988 camaro- Also scrap

'05 Silverado- You guessed it, scrap

1988 TRX 250R- Ported w/ high compression on 110 octane- Out 60' your LT1

Jersey Shore Street Car Takeover (JSSCT) Founder

Quote:

Originally Posted by LS1ow

and once i get PHB, what do i ajust it too?

|

Quote:

Originally Posted by Jersey Mike

Seven.

|

|

|

|

02-01-2022, 08:25 PM

02-01-2022, 08:25 PM

|

#455

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

thanks fellas. It is coming along, and I hope to have this thing on the road in a few weeks.

The 880 rod was reccomended to me by the guys at the County welding supply store that I go to often. Since I will be doing tig weldign on various metals, I needed something that could be used to join different metals. I do have some stainless filler rod (I forget the number) but it is 3/32" and would probably have been too big for the v-band flange there. On the opposing/mating v-band flange (which is stainless) I will have to weld this to my 3" diameter collector pipes which are aluminized steel. I never planned on doing a full stainless collector pipes, especially since the flex-pipes are not stainless anywhere. The o2 bungs are stainless, but all the 3" pipe is not. So the Weld-Mold 880 rod is what I decided to use because it is considered to be the best affordable multi-purpose filler rod for dissimilar metals, at $28 per pound.

__________________

1987 IROC-Z - modified

|

|

|

02-02-2022, 06:34 AM

02-02-2022, 06:34 AM

|

#456

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

If you can, try to have both V band flanges clamped together when you weld them. Even when you do that, verify the flange did not warp after welding.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

02-02-2022, 09:32 PM

02-02-2022, 09:32 PM

|

#457

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

definitely, for sure. Great idea. I do remember hearing that while watching some v-band videos, and I am glad you brought it up... because I was getting all excited to install the headers tomorrow. But now I'll weld up the other sides of the flanges and that way minimize potential for warping. Thanks man

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 02-02-2022 at 09:32 PM.

|

|

|

02-13-2022, 09:35 PM

02-13-2022, 09:35 PM

|

#458

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

The garage and my tools have been taking a beating recently and currently R.I.P to my trusty angle grinder, a electric drill, my bench-mounted vise, and something is jamming up the wire in my MIG welder. Everything is dirty and metal shrapnel/dust over everything. getting impatient to wrap this project up and do a garage re-set and cleanup.

Anyways, I spent some time bending up all new transmission fluid lines to replace the oem steel ones that had been well abused, bent, cut up, and simply always in the way for many years. I made nice clean new ones out of 5/16" copper-nickle tube and flared the ends. I also re-routed my fuel lines, rear-brake line, fuel pump wiring harness, and oxygen sensor wiring harnesses, higher up inside the trans tunnel to keep them away from exhaust heat. They should all be safe from moving objects and heat now, and I will probably wrap them in that heat-shield sleeve stuff later on. I got the two powdercoated pulleys on the engine too (no belts yet). Added in a secondary oil pressure line which will go to a new autometer oil pressure gauge on the A-pillar. Also bought a nitrous pressure gauge and the AEM UEGO X-series wideband oxygen sensor. Only the oil pressure gauge was hooked up so far, but not yet installed in the A-pillar.

(probably going to roder that silver bezel for the AEM gauge so it matches the silver bezels on the nitrous and oil gauges.

After all that was installed, (and the headers with new gaskets), I wanted to check for leaks before proceeding with the fabrication of the collectors and merge pipes. So I got all the car's electronics hooked up and fired it up. I put the sniper in open loop, because I did not have the oxygen sensor installed.

--- Damn, this thing I was way louder than it ever was with the dyno-dons shorty headers. I decided to take a video of it, and the phone camera/microphone really does it no justice. Its loud in a good way, but too damn loud and if left like this it will be causing a ruckus everywhere. I am curious to see how the volume changes once the collectors, merge pipe, 4" pipes and magnaflow muffler are in place.

video:

https://www.youtube.com/watch?v=-1Z4ayM82tM

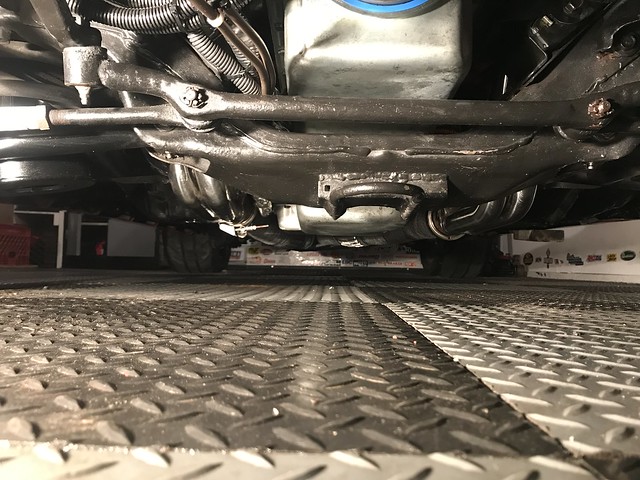

I had a few hours real quick today to try to fab up some collector pipes. I originally intended to get all creative with stainless 3" pipes and lots of pie cuts, but this project is wearing me down and I decided to just use some of those 18" long 3" diameter sections of pipe from autozone for $12 piece or something. I did a few pie cuts, but I don't have a metal chop-saw with a base-clamp, so I essentially just used the angle grinder to guess my best guess at some angles and chopping things up. If I gotta re-do this one day, I'll make it more professional, but now its more about getting the project done and moving onto the next stuff...because Island Dragway opens March 6th this year.

-I used the TIG to tack the pie-cut pieces in place, which was NOT my initial plan. I was going to tack them quick and easy with the MIG welder while everything was under the car, but the MIG is acting dumb. So I had to lie on my back, holding the TIG torch in one hand, filler rod in another hand and using either my shoulder and sometimes my knee to work the welders foot-pedal amp control. Not how I intended to do it, but its tacked in place and now I can put the pieces on a bench and weld them up properly... after I go get more Argon, because the bottle ran out today as I was tacking stuff in place. Just can't win recently !

not thrilled about any of these quick-n-dirty tack welds, but they are holding and I will get it all zipped up nice on the bench once I get TIG gas refill.

The headers themselves do fit good. I did run into a clearance issue when I went to index the starter, so I had to cut a slice off of the mounting area on the starter body so that the starter gear could index the flexplate properly. I built a bracket/hanger off the starter to hold the trans lines too. I've noticed that the drivers side header does come down a bit lower than the passenger header, and there is nothing I can do about that, so I just worked the 3" collector pipes on each side accordingly. I do like these v-band clamps at the header/collector flanges, so i am glad I did that. Not sure if I will cut in a v-band at the 4" pipe too, but for now, I am going to leave the area where the flowmaster merge pipe connects tot he 4" main pipe as a slip fit with a band-clamp. Can always change it later on.

As for the oxygen sensors.... My gameplan has changed from a few weeks ago when we discussed where to put them. I initially planned on them landing somewhere near where the tailshaft of the trans is, but thats where my flex-pipes are. So I am going to squeeze them in alongside the trans body right about where those red pieces of tape are. They will be angled just slightly off from vertical, so basically at the 11:00 position and the 1:00 position. Anyone foresee any problems with that? Its about 8ish inches away from the header exit, so the airflow will have a blend of all 4 primary pipes. Thoughts?

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 02-13-2022 at 09:52 PM.

|

|

|

02-14-2022, 07:11 AM

02-14-2022, 07:11 AM

|

#459

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

I hate being the negative nancy, however, NHRA prohibits fuel lines running down trans tunnel. A broken u joint, or driveshaft can and will grab them, just a thought.

Safety stuff is important.

Otherwise, the Y pipe looks great! If the vbands don't seal up perfectly, run a bead of rtv copper on the surfaces and clamp em up.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

02-14-2022, 08:14 AM

02-14-2022, 08:14 AM

|

#460

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,342

|

I like the O2 position better. Don’t the liners on mig guns **** up sometimes causing wire feed issues? Try laying it straight and see if it feeds.

|

|

|

02-15-2022, 09:11 PM

02-15-2022, 09:11 PM

|

#461

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

great point Matt. Ok, i'll see what I can adjust. Most of the lines in the trans tunnel are tucked up quite high now, but the ones near the driveshaft tunnel can be adjusted. You are right on that being a safety issue. also, good suggestion about the RTV copper. I picked some of that up as a "just in case" thing. I like these evil-energy v-bands as they have a male/female grove built into the flanges, but it's probably a good extra leak-proofing to use the copper if I think there is a misalignment.

Adam, yea, I am much happier with the location of the oxygen sensors. The other plan was going to be a concern for me. I welded in the o2 bungs today real quick and they are 6 5/8" from the v-band flange. I put a cheapo o2 bung extender and a bolt into the bung while welding to give the heat a place to travel to and avoid warping the bung. I had to put them on an angle because of the curvature of the trans tunnel. I won't be able to unscrew them when this y-pipe is mounted to the headers, but all I have to do is let it hang by the flex pipes, screw the o2 sensors in tight, and then lift the whole assembly up to the headers and tighten the v-bands.

-also yes, I am super hopeful that the mig gun's liner isn't fubar or anything. As far as I was expecting, the mig gun liners is probably as old as the welder itself, which is mid 1980's. I am going to try to fiddle with it this weekend because I will need the mig welder to weld in the actual exhaust hangers which will locate the mufflex pipes and magnaflow muffler. I don't think the tig will be up to that.

--sidenote, while welding up those pie-cuts yesterday using the tig torch, I adjusted the flexible head like I usually do in tight spots, and heard/felt a crack from the torch gun. So, the torch is no longer an adjustable head, but now it also isn't fixed...it just kind of bobbles around...which is super difficult to get a crisp weld line. DAMN! another tool busted up.

so, yea, now that the pipes are welded in and the bungs, the last thing I have to do is weld up the joint between the flowmaster 4"to3" merge and the silver mufflex slip-collar.

-After thats done, I am going to scuff the whole thing, prime the whole piece (not the flex pipes) with VHT primer and then some VHT paint. Then it will be time to put on the header pipe-wrap. I know that like Brian said above it will hold oils and debris, and its a pain to work with the fiberglass , but I am fully interested in keeping the heat in the pipes and less radiating to the nearby trans, fluid lines, fuel lines, floorboards, and whatnot. My biggest question is, should I wrap those flex pipes too? Did some research and some people in-fact do wrap flex pipes. They suggest wrapping the flex pipe as a separate section, in case I gotta take that part off... I wouldn't have to unspool the whole y-pipe assembly. I am not going to wrap the mufflex main pipe or anything past the drivers seat area, so basically JUST this y-pipe. Thoughts?

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 02-15-2022 at 09:31 PM.

|

|

|

02-16-2022, 09:54 AM

02-16-2022, 09:54 AM

|

#462

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Heat shields are your friend. See if you can rig up shielding that mimics how OEM's do it. Space it above the pipe and clamp to it, should radiate heat down fairly well.

I wouldn't suggest wrapping em, their too close to the ground and you will end up with a frayed mess after a year or so of driving.

Alternatively, something like this could work well for you, again with the insulation facing the car.

https://www.summitracing.com/parts/t...4aAtiXEALw_wcB

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

02-16-2022, 11:54 AM

02-16-2022, 11:54 AM

|

#463

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

Damn, a shield would be better yea, but I definitely don’t have any head room above the pipe to work anything in there. I can barely fit a finger above the pipe in most areas. I did my best to do this so I could Maximize ground clearance . Saw those

Heat sleeves. That might be something I might do in the future yea. Already bought the heat wrap a month ago and the metal zip ties .

It might get messy over time yea, I guess I’ll have to take that gamble and switch it out if needed. I know for Sure that there are 3 chassis points that are a good 3/4” below the lowest part of this y-pipe arrangement so if I do hit pavement, it won’t be exhaust, it will be frame/car/tubes. I definitely Agree with ya but I’m hoping the wrap will do a littttle bit to

Help Heat, and maybe I could do a sleeve later on. I’m getting impatient to

Wrap this whole project up and do some Test drives, and then hopefully order the new rear drag wheels and tires soon too

__________________

1987 IROC-Z - modified

|

|

|

02-20-2022, 09:03 PM

02-20-2022, 09:03 PM

|

#464

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

Got the y-pipe cleaned up, sanded down, and shot it with VHT primer followed by a coat of VHT paint. Across all my avenues of car buddies that I asked, most said to avoid the heat wrap, but some said to do it thats the route I went (for now). if it turns out to be a problem, I'll just take it off. I used plenty of metal zip ties and faced all of the tails upwards. Out of the 50 foot rol of heat wrap, I was only left with about 1 foot of leftover. whew!

I installed both HBX-1 oxygen sensor extenders (important for nitrous) and then I installed the holley o2 sensor in the drivers side bung and the new AEM o2 sensor in the passenger side bung. When it was all said and done, they are 6.5 inches from the v-band at the header . I am happy with the placement and the angle of them. Bolted up the y-pipe and those v-bands work great; they just sucked everything together nice and tight. Took some time to locate the best position for the main 4"pipe and welded on a hanger for it. Got the up-and-over axle pipe in, as well as the magnaflow muffler. Welded up a hanger for the tailpipe and tightened everything up. I will re-tighten all fasteners after a few heat cycles. Did a test fire up in open-loop and was happy that the violent sound of the open headers was noticeably muffled. For a street-car, this is perfect. In the video (iphone 7 camera) it sounds quieter, but it has some deep ground-pounding thump to it. My experience with magnaflow mufflers has been that they are a little quieter at first and after a bit of use, it will get a little louder. Not sure if its for other styles of magnaflow mufflers, but we will see. As it is right this moment, its really good sounding. However, no matter what, this whole exhaust system will flow tons better than my old system, and that was the primary goal.

video:

https://www.youtube.com/watch?v=mLdrrhktakU

some photos.

Next, after tightening fasteners, I want to check/adjust the driveline angles since things probably shifted a bit when I built the whole trans-crossmember. Some other quick undercarriage projects and then its time to get this thing on the ground, so I can road test it and take some measurements of the underside clearance on everything exhaust/frame related. After that, I have to install the 3 new gauges into the a-pillar gauge pod and install carpet, seats, and whatnot. Then it is on to probably a few measurements and ordering the new rear drag wheels and tires.

still mostly thinking of the 15" Jegs ssr star wheels (to match the front skinnies) and then a MT ET Street SS tire in the 275/65/15 range.

__________________

1987 IROC-Z - modified

|

|

|

02-21-2022, 08:06 AM

02-21-2022, 08:06 AM

|

#465

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,342

|

Looks and sounds good, Dave. Nice work as usual.

|

|

|

02-21-2022, 05:27 PM

02-21-2022, 05:27 PM

|

#466

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

She sounds good! Beard is filling in nice too!

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

02-21-2022, 07:55 PM

02-21-2022, 07:55 PM

|

#467

|

Join Date: Sep 2010

Location: Hackettstown, NJ

Posts: 165

|

Dave, sounds great. Bet you can't wait to get it to the track

__________________

57 Chevy - 210 - 355 SBC-Powerglide-10 Bolt 3:73 Gears - 12.78 best et - 104.78 MPH-street driven

80 Firebird-350 SBC-Turbo 350-10 Bolt 3:42 Gear - 13.69 best et @ 97.52 MPH

96 Buick Roadmaster wagon LT-1 - (DD) for sale

2023 Equinox - wifey's car

22-Ford Maverick-FWD Eco

|

|

|

02-21-2022, 09:39 PM

02-21-2022, 09:39 PM

|

#468

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

thanks fellas. If anyone notices anything concerning or has advice, as always.. feel free to shout it out. I would rather make changes to the car now instead of later. That's the reason I post all this typing/photos, so that if I am doing anything way-off, someone can steer me in the right direction.

- It does sound good, but I'm eager for the magnaflow muffler to get worked-in because I'm 99% sure it will get a little louder and then it will be perfect. I'm like 95% happy with the sound. Also, with the car on the ground and the exhaust pulsing off the pavement, that might change the sound a little bit.

I'm glad you guys steered me away from the exhaust cutouts, that would have been such a headache, and not worth it for flow or sound. Much thanks. Oh, yea, beard is good, prob going to shave it off in a month or so; as I only usually do it for the wintertime and then it gets a bit annoying. But thanks, wife likes it too!

I'm excited to get to the track yup, but I still need to put in a bunch of road testing first; and order the rear wheels and tires soon too. I gave the whole underside a wipe down and checked some bolts today after work. I played around with the adjustable torque arm and driveline angles a bit, but I want to revisit my measurements after I give the car a drive to shake out the suspension a bit. Then I brought the car back down to the ground. Was very very pleased with the overall ground clearance. For reference, I put a soda can and a 4"x4" wood block that I took a true measurement of it and it was 3.5" tall. So, using that as a gauge, I spot-checked a few key areas. I have at minimum 4" of ground clearance, so that is a big win. Will see if anything changes after a few shakedown drives of the car, and I'll then also tighten up all exhaust bolts.

__________________

1987 IROC-Z - modified

|

|

|

02-22-2022, 08:37 PM

02-22-2022, 08:37 PM

|

#469

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

If you can, turn the V bands so the threaded rod is vertical and tucked up more. All it takes is a rock or similar to chew up the threads and life gets miserable.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

02-25-2022, 10:06 PM

02-25-2022, 10:06 PM

|

#470

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

very good point. I will certainly do exactly that on Sunday when I get back under the car to tighten a few things after some heat cycles. Thanks man, you are right.. if those threads got boogered up by something, it would indeed be a bad day.

During the exhaust project I installed a second oxygen sensor bung so I could visually monitor the passenger side exhaust gasses of the engine. Prior to this, I only had one o2 sensor and it was in the drivers side header, which is all the holley sniper ever needed.* *So, I bought a 3-pod a-pillar gauge cluster and installed an AEM afr gauge (with its wideband sensor), an oil pressure gauge, and a nitrous pressure gauge. Turned out good, I like it.

Next, is the rear drag wheels and tires. I think I am 95% settled on what I want to order, but I figured I would run it past the group first.*

Wheels:*

-Since my front drag wheels are the 15" Jegs SSR star wheels, I will be going with a matching Jegs SSR star rear wheel. I don't need a 10" wide rim and the headaches it may cause on my lowered car with inner wheel clearance. So, I think the 15"x8" wheel is what I will buy.* As for backspacing, there are only two choices, either 4.5" or 5.5" backspacing.* I like a wheel with a deeper dish as opposed to the look of the face of the wheel outboard. Running the numbers and measuring puts me doing good with a 4.5" backspace but 5.5" might be a little tight around the parking brake mechanism. I have those C4 corvette style brakes (Lt1 style ??), so they are larger than stock.* just for the heck of it, I bolted up one of the 15" jegs front-skinnies and played around with the spacing/measurements. It might be tight, but I think it will work.

4.5" backspacing*link:* https://www.jegs.com/i/JEGS/555/680272/10002/-1

or

5.5" backspacing link: https://www.jegs.com/i/JEGS/555/680278/10002/-1

Tires:

My current MT ET Street SS dot tires are on the 16"x8" iroc wheels and are a 255/50/16, which are about 26" tall.* *I am looking for a 28" drag tire that will help stretch out my gears at the top end of the track, and since the MT ET street SS rubber has never let me down, it would make sense for me to stick with that tire, just in a 28" tall version. I have probably close to 80-90 dragstrip passes and 500plus miles of street driving on these tires and they are not really too worn down, so a new (taller) taller set will get me a couple years of use. I think anything else, like those et street radial pro or the hoosier radials is overkill for my car and despite being stickier, would wear down within a*year of use. Most of those tires are on backorder too, yet this ET street SS tire is available to purchase/ship right now.* So,* The 28" tall MT ET street SS tire I would get would be the 275/60/15.*

link:

https://www.jegs.com/i/Mickey-Thomps.../3453/10002/-1

I plan to sell the current IROC-Z wheels with current mickey thompson drag radials in a few weeks once the new wheel package is good to go, so if someone wants a pair of oem iroc wheels with sufficient rubber left on a set of well proven drag radials, let me know and I will sell them to you at a fair price, but not interested in shipping them

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 02-25-2022 at 10:26 PM.

|

|

|

02-26-2022, 07:38 AM

02-26-2022, 07:38 AM

|

#471

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,342

|

Shaving the cooling fins down some is a typical mod to get the clearance needed.

|

|

|

02-27-2022, 08:38 PM

02-27-2022, 08:38 PM

|

#472

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

Yep, I am totally up for doing that and hopefully thats all it turns out I need to do; a little buzzing and some paint.

Some shaving of the e-brake stuff might need to happen, but I'll cross that bridge if I need to. I spent some time on the corvette forums (since they run these C4 corvette style brakes) and did read that some people indeed had to grind down some cooling fins. Some of their posts were pretty old and even though they used a jegs ssr star wheel, those star wheels were designed different back then ... if you guys remember my old front jegs star skinnies, the whole backside of the wheels was bigger and bulkier. But just this past year when I bought the replacement jegs star skinnies, the new design/mold of both the front and the back is different and less bulky. So the old posts I read were kind of useless...and basically I will just have to order the wheels and mount them up to find out.

Placing the order for the new wheels/tires before the end of tonight.

..... last bit about the wheels. but back in the Fall I had a chance to try out my buddy John's rear drag wheels which were a 15" diameter wheel and running a Hoosier Quick Time Pro tire which measured 27x10.5 15-LT . I was curious about overall height and also about inner wheel fitment of a 15" wheel with my brakes. The calipers cleared by just a very slight bit, but his backspacing was about 5.25" and I had contact between the parking brake brackets and the inner barrel of his wheel...even left a small scratch. I know its a different wheel and design, but that's all I really have to go off of.

Photos of his wheels

His wheel next to the wheels I ran for the past two years 27" vs 26"

Took the car out to fill up the gas tank with 93 since its been low on fuel all winter. Got into the throttle a bit and left some tire smoke trails in the process, with no hood on. Car ran good and exhaust sounds good. Header wrap is still smoking a tiny bit, hopefully that goes away soon, it gives off a unique smell. When i got home, despite the roaring wind, a few neighbors lent a hand and we got the hood back on the car too.

Boxed up one of the two Stroud 5-point safety harnesses and I am sending it back to Stroud for a re-certification since my SFI on those harnesses expires June 2022. $65 plus shipping.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 02-27-2022 at 08:51 PM.

|

|

|

03-04-2022, 09:05 PM

03-04-2022, 09:05 PM

|

#473

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,120

|

__________________

1987 IROC-Z - modified

|

|

|

03-05-2022, 06:50 AM

03-05-2022, 06:50 AM

|

#474

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

28s FTW!

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

03-05-2022, 08:57 AM

03-05-2022, 08:57 AM

|

#475

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,342

|

Plan to check alignment? Wondering how things are sitting now with the new height. Looks good though!

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|

|