|

|

09-23-2023, 12:07 PM

09-23-2023, 12:07 PM

|

#601

|

Join Date: Jul 2011

Location: harmony, nj (phillipsburg)

Posts: 517

|

were you at island last night dave?

__________________

1994 Firebird Formula - Injuneer's car - NEW PB 9.90 @131

2021 Charger Scat

Wrench/driver 94 Camaro Ellwein 385/D1SC/CPT 4l60e/9" slow pile

|

|

|

09-24-2023, 08:15 PM

09-24-2023, 08:15 PM

|

#602

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

I was! It was last minute on Friday when two of my buddies told me they were thinking of going, so I decided to take advantage of the only non-rainy day this weekend and go on Friday night's TnT. I have to get all that written up and the videos/logs/timeslips are still on my desk.

Its a shame it took me this long to get to put all the photos, videos, and files in one spot, but here is most of it. Will add more later on.

Took the car to the Chassis Dyno back on September 8 for a second go at it. The new distributor had been working perfectly so I was good on that respect. The goal for the day was to find real-world torque and hp curves and see how different it is compared to the engine dyno printout that was from when the engine was first built brand new (no accessories, open headers, dyno stand setup). Below is that printout, which was from February of 2020 at Nyes Racing Engines. I also wanted to see if I could get the jetting on teh nitrous checked. I strapped a Go-Pro camera to the underside of my hood also, pointing directly at my fuel pressure gauge so see if I lost fuel pressure at all during a WOT pull.

Got the car strapped down and discussed what we needed to. I had realistic goals for peak power, knowing that I'm sure my numbers have diminished with an automatic transmission, my 12 bolt, front accessory pulleys, and 3 years of significant wear and tear (113 dragstrip passes and 57 autocross laps, plus untold street activity). I had hoped for at minimum 400 wheel hp and 375 torque on all motor runs. As a high number I was thinking 420 rwhp, as thats how it feels driving it.

I said, for the hell of it, lets do the first pull with the air filter and lid on.

Dyno Pull 1:

35 deg WOT timing, 93 octane pump gas, targeting a 12.8:1 AFR, air-filter and lid on, .035 gap on Autolite 3923 plugs, 3rd gear WOT, only pulling to 5500for now. at WOT converter flashed to right about 4800 and AFR held pretty close to 12.8 on the drivers side o2 sensor which is the datalogged holley one. The datalog shows that it puled to 5848 rpms, but the dyno graph shows it was loosing power rapidly after 5,100 rpms.

(I do not have a video for this or the second dyno pull.)

354 hp and 364 tq

Dyno Pull 2:

same timing, same everything except we took the air filter and lid off.

Printout is not printable for some reason, but the numbers were

From a steady 3100 rpm to wot the converter flashed to 4836 rpms and the afr got a little nutty with going lean. it caught itself and leveled out and pulled to 6086 rpms on the log,

366.4 hp and 375.2 tq

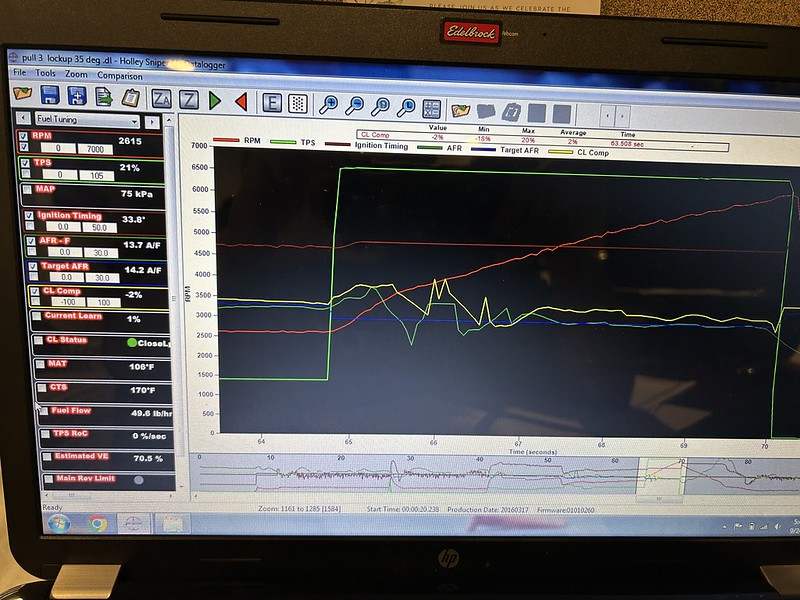

Dyno Pull #3

Same settings, decided to lock up the converter during 3rd gear.so, from a 3rd gear 2644 rpm and the converter locked up, it never flashed, and just climbed slowly to 6285 rpms

The AFR was a bit nutty for a few seconds early on. I'll have to check those VE cells, they may have never been cleaned up since I never usually lockup 3rd gear and go WOT

No hp gain from previous pull, but it lost some torque.

367 hp and 367 tq

https://www.youtube.com/watch?v=tUJpgkzWZQo

Dyno Pull #4

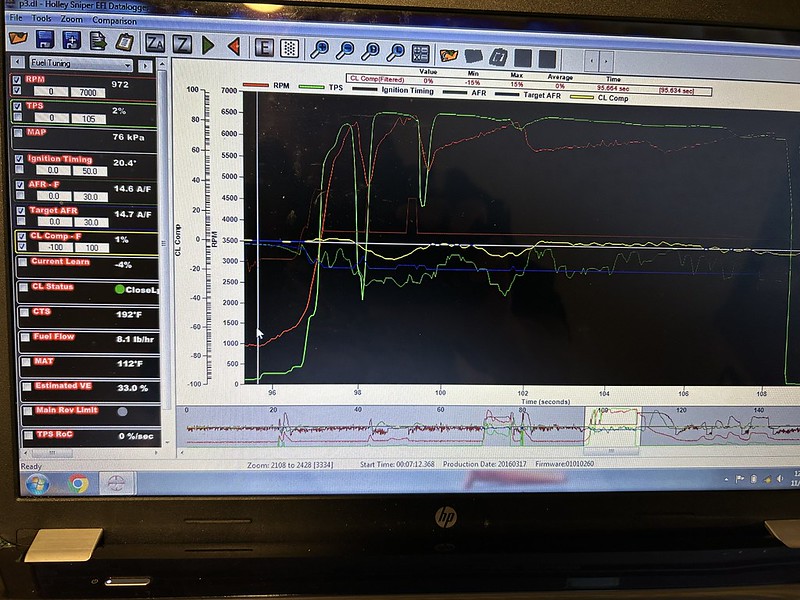

Decided to not-lockup the converter, and only to change the ignition timing and see if it gained any power going from my normal 35 deg instead to 37 deg. It picked up a little bit, but not sure if its justified to push the limits with 37 deg for that small of a gain. To Be Determined.2499 rpm steady to wot, and for some reason the log appears likethe converter was locked since there is no flash. With 37 deg of timing there were no big signs of detonation on the rpm trace of the log and the closed loop comp numbers I can live with and adjust what I need to from this data.

https://www.youtube.com/watch?v=5whX4hzQxKo

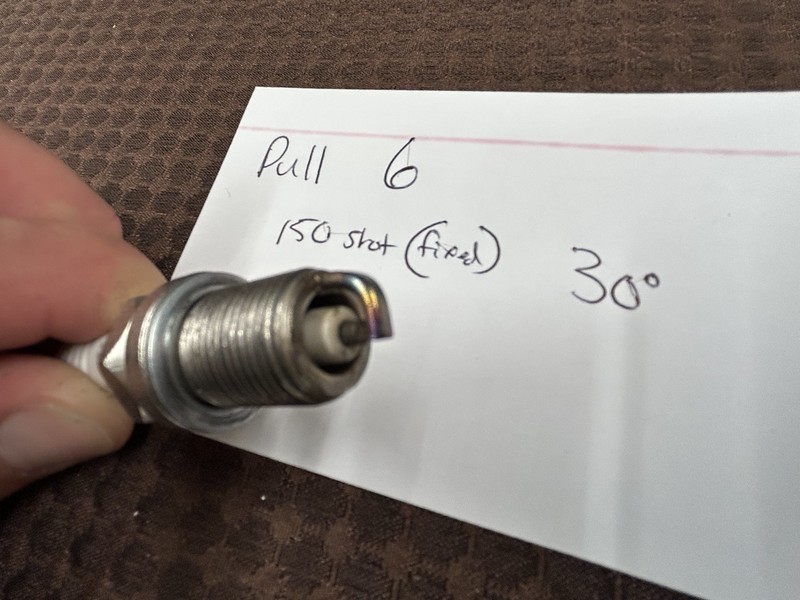

We had previously decided to check spark plug #7 throughout the day, mostly for the nitrous runs.

We used the same plug on all four of these above all-motor pulls and here is a photo of it.

I mounted the go Pro under the hood , and the shaking in the video is the hood vibrating, the engine is not shaking around that much. This video is probably pull#2. to get a video of the mechanical fuel pressure gauge and making sure it stayed close to 60 psi.

https://www.youtube.com/watch?v=32fqQbRLgCA

While I was pretty happy to see that how I have recently been tuning the car was decent, ... but I was definitely pretty shocked about the really low peak power numbers in all 4 motor pulls.

The engine dyno made peak power 531 at 6,000 rpms with 36 deg timing and I could only manage to put down 374 hp at5,600 rpms. Not expected, and mathematically that works out to be exactly a 30% powertrain power loss. Woah!* If I am only truly putting 374 hp and 378 tq to the tire, I am surprised I run 11.60s and 11.70s at the track with a 3600 pound setup. Interesting. But my car has always felt underwhelming most times, so therefore it does make sense.

So overall peak numbers: 374 hp (pull 4) and 375 tq (pull 2). I will have to dig into looking at the power curves a bit better to use them to determine if I should still try to shift past 6,000 rpms like I usually do?

Nitrous stuff in the following post.... might be a few more days before I can get to typing that up.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 09-30-2023 at 01:32 PM.

|

|

|

09-25-2023, 03:17 PM

09-25-2023, 03:17 PM

|

#603

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Were you monitooring trans temps?

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

09-25-2023, 09:11 PM

09-25-2023, 09:11 PM

|

#604

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

Yup, definitely. It was definitely 140 - 160. never got hot at all, we verbally confirmed it with eachother a bunch of times throughout the day as I was under the hood swapping out spark plug #7 and he was in the car looking over the datalogs. Mid way through the day we gave the car a 45 minute break too.

__________________

1987 IROC-Z - modified

|

|

|

09-30-2023, 01:26 PM

09-30-2023, 01:26 PM

|

#605

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

I edited the post above to include the dyno printout from pull #2. I had the file re-sent to me.

I am also listing the clock's time during the pull, so we can see how long there was in between each one.

1. 10:42 am (all motor 35 deg no lockup air filter on)

2. 10:53 am (all motor 35 deg no lockup air filter off)

3. 11:09 am (all motor 35 deg lockup on)

4. 11:24 am (all motor 37 deg no lockup)

- an hour break in between before starting nitrous

5. 12:24 pm (150 shot no lockup)

6. 12:42 pm (150 shot no lockup again)

7. 12:55 pm (150 shot lockupon)

8. 1:34 pm (jet change to a 175 shot, no lockup)

9. 1:49 pm (200 shot, no lockup)

10. 2:06 pm (175 shot, no lockup)

- 1 hour break again

11. 3:03 pm (back to the original 150 shot no lockup)

- Still haven't had time to really dig into comparing the datalogs to the dyno graphs and figuring out what I need to figure out. Hopefully soon, just putting the photos and videos out there in the meantime.

Nitrous pulls:

Pull 5:

I typically keep a 150 shot jetting in the system, which is a .059 nitrous and .030 fuel jet, so this is where we started. I added a half can of the "Race Gas" actual fuel octane additive to the fuel tank when we were done with all-motor pulls. I always target a 12.4:1 AFR when on the nitrous, and for a 150 shot, I was pulling out 5 degrees of timing. So all motor 35deg, minus 5, is a clean 30 deg on the wet 150 shot. The resulting power numbers are pretty much on-point for what a 150 shot should produce to the wheels, and it was a gain of 139 hp but only 95 foot pounds of tq. Odd, also odd was the general trend of the datalog reading more rich because typically I see lean afr numbers. On the datalog, you can quickly tell when the nitrous was hit, as the horizontal yellow line is my ignition timing and it goes flat 35 deg diagonally down to a flat 30 deg during the pull, until the last moment when Jeff got off the nitrous and stayed WOT for a moment afterwards as a safe way of ending the pull.

505 hp and 470 tq

https://www.youtube.com/watch?v=LIMlwqGeP0M

Checking fuel pressure with Go-Pro Camera pointed at gauge

https://www.youtube.com/watch?v=fN3LYSQI9x4

Pull 6:

We did the exact same pull, changed nothing yet, but Jeff wanted to watch the other O2 sensor, not the holley one. The 3 year old holley one is the drivers side header and is the one that has been responsible for all the datalogs I have ever posted. The AEM gauge is on the passenger side header, and I have a digital gauge in my A-pillar, but this is not datalogs and is only for my visual reference at this point in time. It also read rich, Jeff saw most numbers in the 9, 10 and 11 AFR during the pull. I mean, its way better than going lean, but now I am wondering why the efi is lean at the track and rich at the dyno. Optimally, the horizontal blue and green lines should be married together as tight as possible, that is certainly not the case here. However, this was the best the car would do, everything else the rest of the day was worse. In total, the 150 jetting gained 149 hp and 111 in torque to the wheels. The peak numbers were also at pretty much the same 5700 rpm area. The two graphs aren't really able to be laid over each other because they have different axis (time, power, rpm) but the graph shows it falling off hard right at 5700, so if you go to my datalog, thats right where the "trouble begins". See the brighter red line, thats rpm trace. When Jeff goes WOT it climbs up fast, but then once either the converter grabs ( I think) the rpm climb slows way down and the AFR begins to get wacky.

515 hp and 474 tq

https://www.youtube.com/watch?v=k9S8HXcs1Vc

Pull 7:

before changing jets, we wanted to see how the car would react to locking up the Yank 3800 torque converter. Same jetting, timing, etc.At WOT, revs started to gain but slowly since the converter was 1:1 locked. Nitrous came on and thats the big climb in rpms where it goes from 3500-4500 but then goes back to slow climbing. AFR trending rich again especially in the middle. It made more torque this way (gained 41 foot pounds, but was a good bit less hp (down by 16 hp).498 hp and 515 tq

https://www.youtube.com/watch?v=CcHyoVnV6UY

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 09-30-2023 at 01:30 PM.

|

|

|

09-30-2023, 01:33 PM

09-30-2023, 01:33 PM

|

#606

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

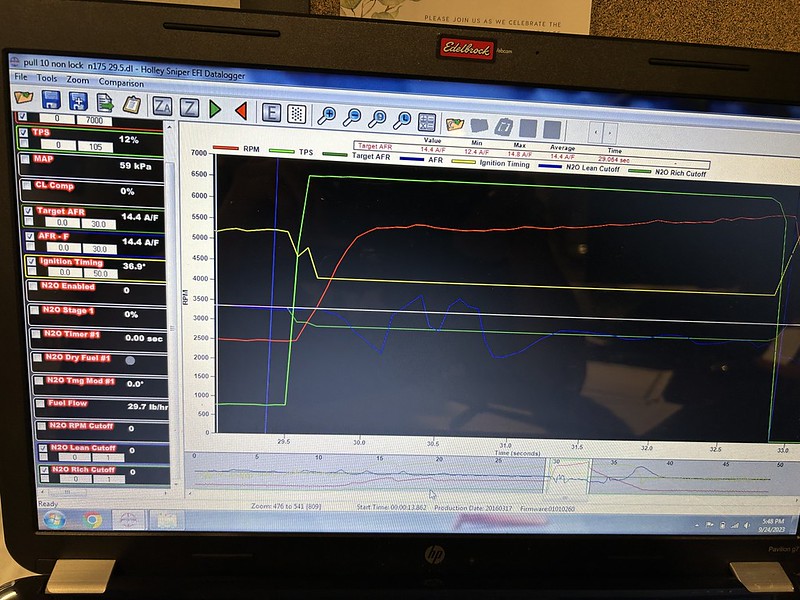

Pull 8:

Curious to see what a 175 jetting would do, I put in the .063 nitrous and .032 fuel jet combination. We pulled out only another .5 deg, for a total of 29.5 deg timing wot. No lockup on the converter, so it flashed to 5500 when the nitrous kicked on. It ran wayyy rich again, climbed slowly, but the dyno graph really shows the big drop in power immediately after the converter gets to 5700 rpms.This now showed that I made more power with a 150 shot than I just did with a 175 shot (lost 8 hp by jetting up).

507 hp and 471 tq

https://www.youtube.com/watch?v=TVx0dQVFjFc

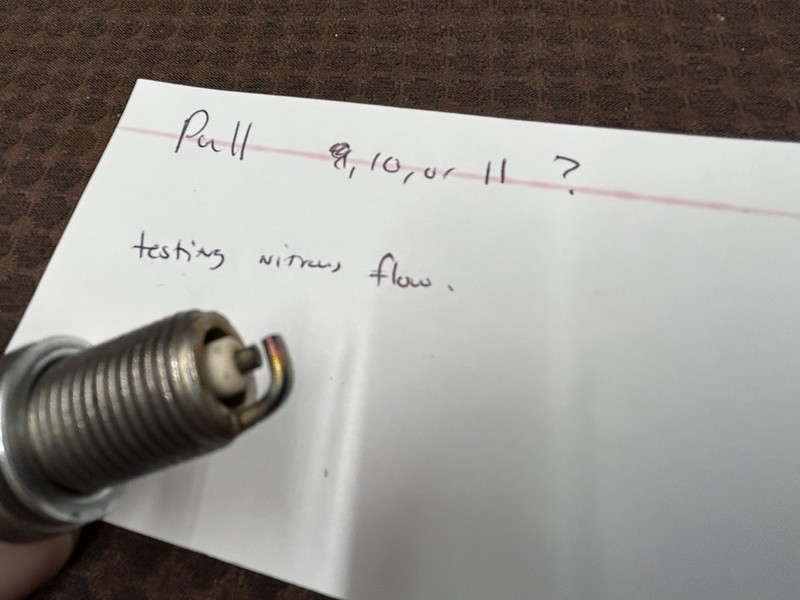

Pull 9:

We started wondering if my nitrous solenoid might be the culprit. These solenoids are now 9 years old and started life designed for just the 100-150 shot lifestyle on my old TPI 305 engine. I have used and abused these things for a long time, so that might be something to look into. The fuel solenoid is rated for 200 hp flow when new, and the nitrous solenoids are 175 hp when new. I knew this when putting the system together, but at the time just wanted a functioning system. If Science says the solenoids are the culprit, I will just step it up. But, to test our theory, we said, lets keep the fuel jet the same as the one of the 175 shot and put the 200 shot .067 jet in for the nitrous. If we still run rich, that will then tell us something. Well, we still ran rich, lost power starting after the converter grabbed, and the engine was telling us it wanted to pull 37% fuel out in CL comp and Learn numbers.

464 hp and 443 tq

https://www.youtube.com/watch?v=AnyNuvzOJjI

checking fuel pressure again,

but

due to this video, I noticed that my jamb-nut on the lokar throttle cable assembly likes to un-thread itself while going WOT, and then re-thread itself when the engine decelerates!!

Can see it in the other videos too. I've snugged it up now

https://www.youtube.com/watch?v=zZTTAjRen8s

Pull 10:

Put the 175 jet back in on the nitrous side and Jeff watched the AEM o2 sensor again to verify it was reading the same as what the holley would show in the log. Rich again, but losing a bunch more power than the previous 175 shot. In fact, it did almost exactly the same as the above 200 shot in numbers. ITs only getting me a good peak number just around when the converter flashes, after that its not gaining so I was less concerned with power numbers, but more as to the "why" of the graph always falling off.

466 hp and 445 tq

https://www.youtube.com/watch?v=AS4b_EXaHI4

Pull 11:

To cap off our experiment, I went back to the 150 jetting that was used on Pull 5, 6, and 7. Same tune as before with 30 deg WOT timing as the shot is activated. Please note, that we were also curious about heat soak and whatnot, but on these logs, my MAT intake temp shows/logged stable numbers around 102-108 deg mot pulls. It flashed at 5500 and then pulled down into rich fueling territory. the CL comp brought it back up to the 12's but it had to take out 30%. Soon, that 30% (my set limit for dyno not for normal use) was no longer enough, and it ran rich 5750 rpms to 6330 rpms. We also considered that I could be running out of nitrous bottle volume. I had the second full bottle with me, but I think we were all done for the day so I called it quits and we began to free the car from the straps.

456 hp and 439 tq

(I have to laugh, that the same 150 nitrous shot that had produced 149 rwhp just an hour earlier, now only produced 81 hp)

ugh, the nitrous struggle continues.

https://www.youtube.com/watch?v=hZ9h3GUPPFs

Armed with all that data, whats the next thing I went and did?!?!

Dug into the science and try to figure it all out?!

Nope, went home, swapped the wheels off, cleaned the car up, and packed because the next morning I drove down to that big FuelFest car show at New Jersey Motorsports Park. That was a long day, but the car racked up 311 miles of driving without a single issue the entire day. So despite a troublesome and confusing dyno day, I still got some dyno data, made 11 pulls, and then put 311 miles on the car the next day.

Then on Sept 22 I took it to Island Dragway; where I had the COMPLETE OPPOSITE results at the track (writeup to follow one day soon).

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 09-30-2023 at 01:37 PM.

|

|

|

10-02-2023, 11:35 AM

10-02-2023, 11:35 AM

|

#607

|

Join Date: Jul 2011

Location: harmony, nj (phillipsburg)

Posts: 517

|

what jetting chart are you using? my single nozzle jet chart shows a bit different jetting. whats the fuel pressure?

__________________

1994 Firebird Formula - Injuneer's car - NEW PB 9.90 @131

2021 Charger Scat

Wrench/driver 94 Camaro Ellwein 385/D1SC/CPT 4l60e/9" slow pile

|

|

|

10-02-2023, 08:56 PM

10-02-2023, 08:56 PM

|

#608

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

I think somewhere back a few pages I might have put a photo of the jet chart. I know I did a lot of research on the jetting two years ago when I first installed the system. Over this past summer, I re-evaluated the numbers and made some slight adjustments. I went to Bruce's and bought a few more at that time.

Aside from looking at the pre-determined charts on some of the reputable nitrous vendor's websites, I also used the robbie-the-robot internet calculator. http://www.robietherobot.com/nitrousjetcalculator.htm

The fuel pressure is 65 almost all the time, and looks like it drops a few psi to maybe 60 psi during the run (as seen in the above go-pro videos). I hadn't found a jetting chart for a single stage single jet plate with 60 psi of fuel so I had to make my own numbers.

This is my quick reference chart, but I also have one that is more expansive

All that being said, I am not sure that the jetting is really the issue, as you will see in my TnT writeup soon, I kept those same exact jets in, and went extremely lean instead at the track! wild

__________________

1987 IROC-Z - modified

|

|

|

10-03-2023, 11:38 AM

10-03-2023, 11:38 AM

|

#609

|

Join Date: Jul 2011

Location: harmony, nj (phillipsburg)

Posts: 517

|

this is the chart i use and its pretty accurate based on my logs, so with higher than 55psi fuel pressure i would be using a .027 fuel/.062nitrous for a 150, and so on. the robbietherobot calculator did not work for me

__________________

1994 Firebird Formula - Injuneer's car - NEW PB 9.90 @131

2021 Charger Scat

Wrench/driver 94 Camaro Ellwein 385/D1SC/CPT 4l60e/9" slow pile

Last edited by townsend; 10-03-2023 at 11:39 AM.

|

|

|

10-03-2023, 09:42 PM

10-03-2023, 09:42 PM

|

#610

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

Quote:

Originally Posted by townsend

this is the chart i use and its pretty accurate based on my logs, so with higher than 55psi fuel pressure i would be using a .027 fuel/.062nitrous for a 150, and so on. the robbietherobot calculator did not work for me

|

Thanks for your reply. I do appreciate the tech help and knowledge.

I like the numbers on that chart, it probably would have been dead on for me on the dyno. One day soon I will have to dig into the math and datalogs between the dyno session and the track datalogs from last weekend. One went crazy rich, and the other went super lean; with the same jetting.

This is the chart I used most of last year, and for a while I had good success. Using the 150 jetting (but it used to be a .058 and a .030) running pretty clean 10.80 and 10.90 passes. Even when I couldn't get the "175" (.063 and .032 or .033), I would go back ad put the 150 jets back in and go back to running 10.80s. Somewhere after that period in time, something went arwy and became inconsistent.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 10-03-2023 at 09:43 PM.

|

|

|

10-04-2023, 09:13 PM

10-04-2023, 09:13 PM

|

#611

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

A few of my buddies were going to the Friday night Test-n-Tune at island on Sept 22, so I jumped in on it. However, I had to thrash beforehand to swap the Boze wheels out for the drag wheels, and also swapped out the Koni yellow front struts for the lakewood 90/10 drag struts. I pulled off the front swaybar while I was underneath there too. I did not have time to swap the rear Koni shocks, and this actually was going to serve as an experiment like Townsend suggested a few months ago, that perhaps I could make my Koni's work better than the non-adjustable lakewood drag shocks. I had not been to the dragstrip since May 28 and I also wanted to see how my dyno results might come into play.

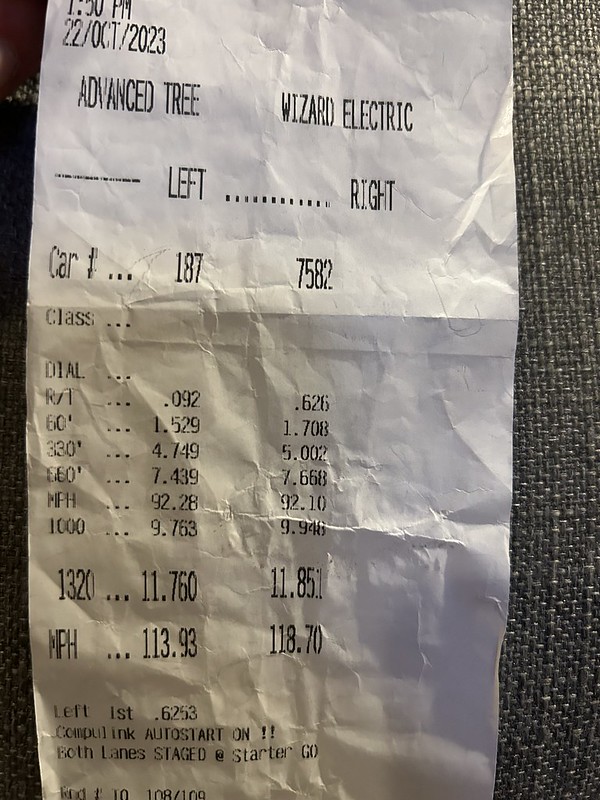

Pass 1:

I was curious to see if the small "gain" in hp that we saw on the dyno when going from 35 deg timing to 37 deg timing would play out. I tried to datalog from the laptop via the usb cable, but I guess I never hit the clipboard button to start logging, so there is no datalog. It was a simple all-motor, 37 deg timing pass. Footbraked to about 2000, went a fast 1.48 sixty-foot, I was clean on the shifts, it just felt like it lost power up top and therefore lost 4 mph (113mph) down from the usual 117 mph. So, either I won't be doing that 37 deg again, or if I do, maybe it would only be with racegas additive in there. The car has always seemed happiest at 34-36 deg WOT anyways, so this was just a test because of what was learned on the dyno.

video:

https://www.youtube.com/watch?v=nc5HFMj3Pnc

timeslip:

no datalog

Pass 2:

Had the 150 shot jets in there. These had just made everything go really rich on the dyno, but in my street/strip use, they have not ever done that, so I needed to re-try them after the dyno. Tried to datalog to the SD card, and that turned out bad, so there won't be any more of that. I need to find a reliable way to mount the laptop in the car and keep the usb cable connected to laptop during its mph pass down the strip. I hate having it fly all around the floorbaord, but that seems like the only way I will get useful datalogs with data points I can read. velcro and some clips maybe?

Anyways, launched from about 2200 and it went hard to the sixty, with a 1.44. I still always feel that slight amount of tire rotation/slip, more about that later on. The car pulled good through the 330 but then the jetting went lean and we were off the spray before the 1/8 mile. I rode out the rest of the pass but now my head starts spinning because its running way lean, not rich!

video:

you can hear it eat itself up right after the 15 second mark. also, that BMW running 9's was fast !

https://www.youtube.com/watch?v=Au2P_AN1cDQ

timeslip:

useless datalog:

Pass 3:

They were calling that the lanes were closing soon so I checked a plug but didn't have time to change the fuel jet (that one takes a while as its in a real hard spot). What I should have done, was just swap out the nitrous jet for a smaller one, since that only takes a minute to change. I did swap back to a 150 shot street-use tune file that I had saved. Anyways, The laptop recorded a nice datalog with datapoints I can use. launched from 2207 rpms, but rolled into the throttle a little slow. So the nitrous didnt come on until later (when TPS was 80% the rpms were at 4900). it still went another 1.44 sixty foot, but I still feel that slight tire slip at the hit though. It still went lean after the 1-2 shift which was 6491 dropping to 5280. With the nitrous off, I pedaled the throttle and let it gather itself up, then early shifted 2-3 (at 6054 dropping to 5305) and finished the rest of the pass on motor ending up at 5906 rpms.

video:

https://www.youtube.com/watch?v=UIKRIeu3uA4

timeslip:

datalog:

[/url]

the tire markings:

After that third pass, while packing up, we all couldn't help but notice the markings on the drag radials. I was surprised, because this can't be from a low tire pressure situation. I have previously gone as low as 16.4 psi on other dragstrip days with good numbers in the sixty foot, yet have never seen these show up. Today, every pass I had the tires exactly the same, at 18.6 psi. From previous test days, I usually don't have a good launch if I am higher than 19.5 or so. Thoughts? Part of me is wondering if the tires are hooking, but I might have an issue with the rim/barrel of the wheel spinning in the tire? Next time I am going to paint-mark them and find out for sure. But, for a good long while now, I've felt that small "slip" at the launch and nobody sees the tire do it, so perhaps its the wheel/tire bead? Not sure.

John's first hit with his new setup.

https://www.youtube.com/watch?v=SUK3lhXJF3Q

__________________

1987 IROC-Z - modified

|

|

|

10-06-2023, 10:33 AM

10-06-2023, 10:33 AM

|

#612

|

Join Date: Jul 2011

Location: harmony, nj (phillipsburg)

Posts: 517

|

mine look like that from when they hook hard on the hit. go up in tire pressure a little. radials like more. i usually start at 18.5 and make a pass, if it feels weird go up to 19. if you crush a radial like that it will wad up then boing and spin a little. 60ft looks like its going the right way. i actually raised my lca up 1 hole on the lca brackets to try to take some of that anti-squat away. you could have em spinning inside, so yeah id chalk them too (ive been meaning to do that as well).

based on the wrinkle its hitting the tire pretty hard and forcing it down. you didnt see this with the lakewoods?

__________________

1994 Firebird Formula - Injuneer's car - NEW PB 9.90 @131

2021 Charger Scat

Wrench/driver 94 Camaro Ellwein 385/D1SC/CPT 4l60e/9" slow pile

Last edited by townsend; 10-06-2023 at 10:35 AM.

|

|

|

10-25-2023, 08:53 AM

10-25-2023, 08:53 AM

|

#613

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

I don't remember seeing it happen with the lakewoods but it could still have been happening.

We had to take a rain-date for the dragstrip group rental that was going to be Friday oct 20th, but I still wanted to get some passes on the car that weekend. The track rental is now this coming Friday, so I hopefully can change and adjust whatever I need to in the next two days.

Sunday was a Mopar event that got combined with a Ford event but there was also limited Test and Tune, so I figured I would get 3-4 passes.

Left the Konis on the car and kept the Lakewood rear shocks in the box again. Air bags were set at 6psi (drivers) and 18 psi (pass). Both rear tires were set at 18.6 for the first pass, and both Koni shocks were at setting 2 out of 5. I am experimenting with putting weight in the trunk area also, and it seems to be helping, so thats why my toolbox is in some videos in the trunk.

Pass 1:

All motor pass, and I wanted to experiment and see if I took my WOT timing from 34 deg and dropped it down to 33 deg once I went past the powerband. Did a 4 second burnout. Footbraked to 2910 where it started to creep, and then it flashed to 4610 on the launch. I shifted 1-2 (early) at 5593 and I took second at 6088 and then finish line was 6081 rpms. I was watching gauges too much and later realized i wasn't full WOT the entirety 3rd gear which is the whole back-half of the track, but nonetheless, it was a decent and typical pass for all motor.

Timeslip: (left lane)

Datalog:

All motor launch:

Videos:

https://www.youtube.com/watch?v=MDgAE2ZINH4

https://www.youtube.com/watch?v=SpTPRWjOVWI

Pass 2:

Kept shocks the same and airbags, lowered tire pressure from 18.6 to 18.0 in the back. The nitrous jets are now different in order to try to compensate for the massive extra amount of fuel that this thing somehow needs. It keeps running lean on nitrous, so I have to keep upping fuel in jets and Cl comp. Nitrous jet for my 150 shot is .059 and fuel jet is now a .030 (up from an .030). I have the timing being pulled to 28 degrees on the 150 shotand it has been happy there before. Race gas octane booster added to fuel tank.

Went into the right hand lane. 5 second burnout, footbrake to 2464 rpms and when I launched, it flashed to 5419 rpms. It definitely launched hard and I shifted at 5975 rpms into second and second into 3rd at 6230 rpms. Once I got into 3rd gear it pulled for a bit but then the nitrous went lean again, despite an additional 20% fuel added by CLcomp. It clicked the nitrous off and I finished the run all motor, to go a 10.91; and I actually shifted into 4th gear overdrive to take the load off the motor. So this car goes pig rich in 3rd gear fueling with nitrous on the dyno, but goes dangerously lean on nitrous on the track. wild. The 60 foot and early track was really good though.

Timeslip:

Datalog:

Videos:

https://www.youtube.com/watch?v=7zR-3hbwtEM

https://www.youtube.com/watch?v=V-s5TN0qb3g

https://www.youtube.com/watch?v=i7emRXJZ6nk

Pass3:

Didnt change anything with the tires or shocks or anything. Even went into the same (right) lane. I opened up the Clcomp limits on the higher rpms to be 30%+- instead of 20%+- hoping that would be enough cushion; it wasn't!

Rolled into the throttle a little slower and launched from a lower rpm, 1378. It spun right when the nitrous came on and turned the car a bit to the right, so I had to get out of the throttle and correct it. Shifted out of 1st ger a bit too high at 6589 rpms and then shifted out of 2nd at 6133 rpms. The nitrous went lean again in 3rd gear and thats how my day ended.

Timeslip:

Datalog:

Video: (my buddy John in the left lane)

https://www.youtube.com/watch?v=Ws6t40PiZhw

https://www.youtube.com/watch?v=Mq6Ir0od3t0

So, testing my theory that that slight amount of slip I often feel on the initial launch might be caused by the rim spinning on the tire bead, I decided to mark the tires. The all motor hit (with a 1.52 sixtyfoot) showed a slight move of the paint marks but I didnt get a photo of this. However after the second launch (with a 1.43 sixty foot) I did noticed this amount of movement. Not that its a ton of movement, but now I know why i had to have them re-balanced and I gotta keep this in mind when launching harder.

Drivers side before and after:

[/url]

Pass side before and after:

[/url]

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 10-26-2023 at 09:42 AM.

|

|

|

10-26-2023, 08:20 AM

10-26-2023, 08:20 AM

|

#614

|

Join Date: Sep 2008

Location: Hackettstown, NJ

Posts: 1,647

|

Maybe I missed it, but do you have a way to log fuel pressure? The fuel trim going lean on the track while being fine on the dyno might be either fuel slosh starving the pump, or maybe the added load of actually pushing the car down the track is overwhelming the fuel system's ability to feed the motor/nitrous demand.

Edit: Was just browsing through your videos, and saw the video with the fuel pressure gauge during a nitrous pull and noticed that the fuel pressure doesn't stay consistent. The initial drop is when the nitrous activated, I'm assuming, but the fuel pressure doesn't stay steady - it's pulses during the short pull. I'd say you might have a fuel delivery problem; if it has a hard time staying steady during a short dyno pull it might be starving out during a much longer WOT-at-the-track run.

__________________

1998 Z-28 - SLP lid - Ported TB - LS6 Intake - Dynatech SS headers/Catted Y - Magnaflow Exh - 3.42 - Yank SS3600 - UMI weld-in subframe connectors, Adj LCA, Adj PHB, Q1A TA - Bolt-in Relocation Brackets - Strano springs - Koni shocks - 17" C6Z06 wheels - 326HP/335ft-lbs - 12.35 @ 110.41

Quote:

Originally Posted by Blackbirdws6

I can appreciate a dream but this person needed some real friends.

|

Last edited by The_Bishop; 10-26-2023 at 08:29 AM.

|

|

|

11-03-2023, 10:09 PM

11-03-2023, 10:09 PM

|

#615

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

The Bishop: I read your reply a week ago and should have wrote back earlier. I remember thinking something like that back when I was doing more autocross, so for the past 4 years or so I always race with a full tank of fuel to prevent any slosh or starving the pump. But also , I am with you about the possibility of g-forces working against the direction of fuel flow forward. Glad you brought it back into the thoughts for me to test out.

I made some great headway with sorting this out, I knew something had to be in the datalogs. If anyone remembers, for at least a year I was having all sorts of wacky/useless datalogs or missing and corrupted files. I feel that that slowed me down, and turned me in the wrong direction. I was following the AFR numbers that I was seeing on the gauges, but anyways here we are. I noticed that on the recent datalogs that I now can save and review successfully, there was a "Rich Cutoff" parameter that is built into the nitrous log-viewing screens. Despite the areas where the AFR numbers would go sky-high lean, this is when the "rich cut-off" would trigger and shut the nitrous off. I also took note of what townsend and Thirdgen.org member skinny have mentioned.

Turns out it is simply just overfueling because of mismatched jetting. I tested a chart that townsend sent me and changed my "150 shot" from a .059 nitrous with a.030 fuel, to be a .059 nitrous with a .027 fuel jet and it got way better. Next pass I went with a .062 nitrous and .027 fuel. Got better again. Next pass I was better yet and it was a .064 nitrous and .027 fuel. The mph kept improving, back to where it used to be over a year ago.

This all still sounds confusing to me, but the theory behind what I understand this issue to be, is that the fueling was indeed rich, but to the point where the oxygen sensors can not read correctly because of excess unburnt fuel and oxygen in the downstream exhaust. I wasn't aware of this until post #493 here : https://www.thirdgen.org/forums/tech...nstall-10.html . I guess I still don't yet get it completely, but at the track rental my new jetting gained me back good timeslips.

__________________

1987 IROC-Z - modified

|

|

|

11-03-2023, 11:38 PM

11-03-2023, 11:38 PM

|

#616

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

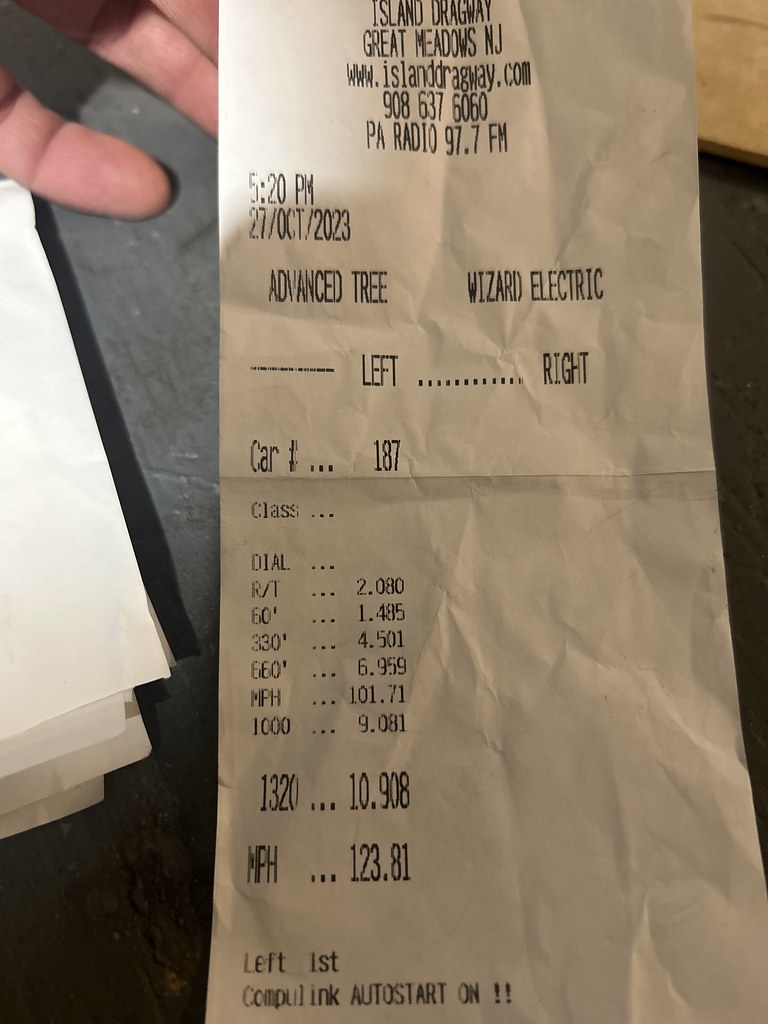

Writing this recap of the track rental session from last Friday, October 27th at Island Dragway.

The weather was way warmer than normal, so the DA was mostly in the 1600-2000 range. We got started way way late but I made 3 all motor passes. Nothing exciting, but on the 4th pass I wanted to test out what would happen if I just got the car into 3rd gear at the 8th mile and sprayed the 150 shot jets (0.59 and .030). It showed high afr numbers like usual, but was not making any mph, but was not problematic to shut off the nitrous. Pulled a plug afterward and it was unhappy rich. For continuous checking throughout the day I pulled plug #7 which is the same one we were pulling while on the dyno.

https://www.youtube.com/watch?v=ezSmhOMEltI

For Pass #5 I changed the jets to a .062 and a .027 and hit the button right off the launch. It finally felt strong, and the 8th mph was back to being above 100 mph finally. It went 11.19 with a bad sixty foot and over-revving both shifts. but.. my mph was finally back above 120 mph and the engine didnt feel like it was eating itself up either. Even last sunday at the TnT when the car went 10.910, it was only at 117 mph and it felt ugly. Now, the mph and power has a proper feel to it.

https://www.youtube.com/watch?v=dUewZOuFGTk

Pulled a plug again and couldn't get a good read on it. Kept jets the same, because it is what the 150 shot jetting is actually supposed to be in the new chart.

Sidenote - I had a heck of a time getting the car to do a proper burnout most of the day. I mean, normally I do pretty much the same routine and it works most of the time. But on the rental day, the car just didn't want to make wheel-speed and wanted to dart to the right a few times. I corrected this around pass 5 or 6 but I had to lay into the throttle a lot more than I usually have to at the burnout box.

Went a 1.48 in the sixty, but hit the limiter on the shift. Made a full clean pass and it was a 11.05 at 122 mph. Still showing datalog closed loop wanting to remove a lot of fuel. Checked a plug once again but it seemed ok.

https://www.youtube.com/watch?v=amXVu12NYq4

This was the launch photo Jerry took during for Pass 6:

Pass 7:

Same jetting as pass 5 and 6. Car went 1.46 in the sixty foot and pulled good up to the top of 2nd gear. And then despite a high afr, the rich cutoff activated again and I finished the pass on motor.

https://www.youtube.com/watch?v=TMLQ1tWAcWs

Pass 8: Changed the jetting to be .064 and .027 . I hit the button late, and despite the power pulling strong, I saw the nitrous bottle pressure gauge drop heavily durign teh run so I knew that the bottle was basically done. This bottle only had 8 pounds in starting on pass 4. The car went 11.25 at 119 mph.

https://www.youtube.com/watch?v=8t4UbPSa7P4

Pass 9, I swapped the bottle and now using the .064 and .027 combo the car made a good clean pass. It went 6.95 at 101mph to the 8th and 10.90 at 123 mph. Afr numbers on the gauges during the run were nice and in the 12s and the plug checked out great.

https://www.youtube.com/watch?v=J1WxCAafZX0

I had to get going home but I wanted one more crack at maybe a 10.70 pass with a bigger nitrous shot, so I quickly dropped in the .070 and .030 jet because I was greedy. It ran , but it wasn't overly happy, so it only went an 11.03 but at 124 mph. It actually was on the top-end rev-limiter again just within reach the finish line, so that slowed me down.

https://www.youtube.com/watch?v=L--5WElt_ug

So, despite me not getting any personal bests, I was pumped up to know that I seem to be heading back into the right direction with mph and et. over a year of nonsense, but finally seeing numbers that are relatable. I am hoping for one more track day of the year, but if not, I know I have a good starting point next year.

On a relate note, I took some photos of the rear wheels/tires after the event, and its apparent that I do have a good bit of wheel movement in the tire bead on both sides.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 11-03-2023 at 11:52 PM.

|

|

|

11-06-2023, 10:00 AM

11-06-2023, 10:00 AM

|

#617

|

Join Date: Jul 2011

Location: harmony, nj (phillipsburg)

Posts: 517

|

happy that you are making forward progress man!

__________________

1994 Firebird Formula - Injuneer's car - NEW PB 9.90 @131

2021 Charger Scat

Wrench/driver 94 Camaro Ellwein 385/D1SC/CPT 4l60e/9" slow pile

|

|

|

11-06-2023, 12:20 PM

11-06-2023, 12:20 PM

|

#618

|

|

The Mayor / 2009 Member of the Year / Moderator

Join Date: Jan 2005

Location: Northwest

Posts: 8,866

|

Quote:

Originally Posted by townsend

happy that you are making forward progress man!

|

Both the wheels in the tires and in his progress down the track.

__________________

1995 Z28 Convertible A4 13.78 @ 100 (CAI, high flow cat, catback, 160 thermo, hypertech, Strano springs, Koni yellows, sway bars, 3 pt. UMI SFC)

2018 Sea Doo GTX - 3 cylinders and das boooooost

Quote:

Originally Posted by BonzoHansen

Is English your 2nd language? Did you graduate high school? Your posts make my head hurt.

|

Team FARM Team FARM

|

|

|

11-06-2023, 12:23 PM

11-06-2023, 12:23 PM

|

#619

|

Join Date: Jul 2011

Location: harmony, nj (phillipsburg)

Posts: 517

|

Quote:

Originally Posted by Anti_Rice_Guy

Both the wheels in the tires and in his progress down the track.  |

he could have my luck

__________________

1994 Firebird Formula - Injuneer's car - NEW PB 9.90 @131

2021 Charger Scat

Wrench/driver 94 Camaro Ellwein 385/D1SC/CPT 4l60e/9" slow pile

|

|

|

11-22-2023, 10:49 PM

11-22-2023, 10:49 PM

|

#620

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

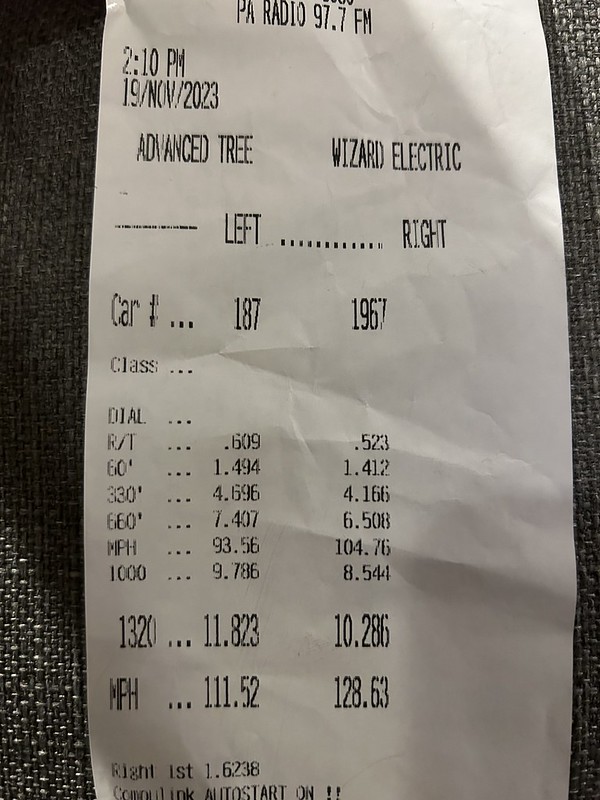

I wanted to get one more day at the dragstrip before the end of 2023, so I went to the Test and Tune on Sunday. Only had about 7 pounds of nitrous in the bottle remaining.

Pass 1:

All motor with 34 deg of timing up to 5800 rpms, and past that its at 33 deg of timing. Rear tires are at 17.0 psi. Foot-braked to 1821 rpms, launched and it flashed to about 5000. Shifted 1-2 at 6401 rpms and 2-3 shift was at 6450 rpms. Across the finish line at 5966 rpms but the back half of the track I was only about 75% throttle as I heard some kind of metal clinking noise under the car. Not sure what it was still.

Timeslip:

Datalog:

Video:

https://www.youtube.com/watch?v=X5A9bdpGIK0

Pass 2:

150 shot of nitrous with jetting at .027 fuel and .063 nitrous and timing set at 28 degrees fixed. Rear tires set at 16.6 psi. Air bags were 6 psi drivers side and 18 psi passenger side. Foot-braked to 2029 and the converter flashed to 5415 rpms. There seemed to be a bit of quick tire spin, but I drove through it. Shifted 1-2 at 6490 rpms, the 2-3 shift at 6364 rpms, and then I decided to activate the torque converter lockup while in 3rd gear, at 6161 rpms and it bought it don to 6004 rpms . The nitrous clicked off just right before the finish line because it was reaching its high-rpm safety limit and I went through the traps at 6317 rpms.

Timeslip:

Video:

https://www.youtube.com/watch?v=mwJwUyDsBlw

Pass 2 launch video:

https://www.youtube.com/watch?v=OSdfnm1DTMg

Pass 3:

Brought up the nitrous to a 165-ish hp shot using a .030 fuel and a .070 nitrous jet. bottle pressure at 950 and ignition timing set to a fixed 27 deg when nitrous is on. Footbraked to 1645 rpms and when I launched, the tires spun bad enough hat I pedaled it. Shifted 1-2 at 6573 rpms (pedaled it here too) and 2-3 at 6487 rpms. I activated lockup again in 3rd gear at 6181 rpms nad it dropped rpms to be 5868. Went through the finish line at 6478 rpms.

Timeslip:

Datalog

Video:

https://www.youtube.com/watch?v=TUKpRZPvxxo

Pass 4:

Brought tire pressure back up to 17.0. Also decided to progressively ramp in the nitrous on the hit, over a 1.2 second ramp. used the same jetting numbers as previous pass, but moved the ignition timing to 29 degrees instead of 27 deg. Brought he rear passenger airbag up to 20 psi. I must not have fully clicked the "start datalog" button on the laptop, and I didn't notice this until on the return road after the pass. I know that I tried to foot-brake higher than usual, and the car began to creep past the beams, so I just decided to let it go. Tires didn't spin but it felt a little sluggish. Right around the 8th mile it ran out of steam , and I think it was simply that the nitrous bottle volume was too depleted.

Timeslip:

Video:

https://www.youtube.com/watch?v=EqoZ__jyCQ8

Pass 4 launch video:

https://www.youtube.com/watch?v=HRR3SCLmSsA

I might need to go with more air int he rear passenger airbag. Or maybe finally upgrade the oem rear swaybar to something better, but nothing too intense.

[/url]

__________________

1987 IROC-Z - modified

|

|

|

11-23-2023, 04:52 PM

11-23-2023, 04:52 PM

|

#621

|

Join Date: Sep 2008

Location: Hackettstown, NJ

Posts: 1,647

|

Glad to see you're making progress!

__________________

1998 Z-28 - SLP lid - Ported TB - LS6 Intake - Dynatech SS headers/Catted Y - Magnaflow Exh - 3.42 - Yank SS3600 - UMI weld-in subframe connectors, Adj LCA, Adj PHB, Q1A TA - Bolt-in Relocation Brackets - Strano springs - Koni shocks - 17" C6Z06 wheels - 326HP/335ft-lbs - 12.35 @ 110.41

Quote:

Originally Posted by Blackbirdws6

I can appreciate a dream but this person needed some real friends.

|

|

|

|

02-21-2024, 09:57 PM

02-21-2024, 09:57 PM

|

#622

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

It has been a while, but I drove the car a bit into December, and it has sat untouched until a week ago. I have a list of projects to tackle on it in the coming weeks, and one of them is to finally do something better/different with my crankcase pressure and annoying oil leaks.

For the past 4 years that this engine has been in the car, it has somehow survived on the terrible setup of having a breather in the passenger side valve cover and an elbow with a 3/8" I.D. hose coming out of the drivers side valve cover and necking down to a tiny 3/16" I.D. vacuum port built into the sniper throttle body. Time to be done with that.

Current:

Best solution would be a mechanical belt driven vacuum pump and all that goes with it, but I don't have the $1300 for that plus then I would want to redo alternator, power steering pump and brackets, which is far beyond budget. Research showed that electric vacuum pumps can be hit-or-miss and a wide range of success-fullness on street/strip cars, but I am going that route. I am going to use a catch can also, and hope to keep the price tag for the entirety of the project around $250. I currently already bought the catch can $105 and an ebay Ford pump $62 and some cheap 1 way check valves, so I think its realistic. This also doesn't have to be the best configuration possible either, thats not my goal; it just has to do better than my existing setup.

Here's the plan that I hop to make work for my car.

- baffles in both valve covers (done)

- both valve covers to get a rubber or rubberized plastic 90* elbow that fits in the 1.22" valve cover hole

- a rubber line off each valve cover (3/8" diameter or 1/2" diameter hose) angled slightly uphill to a Tee-Y

- a 1-way check valve in the 1/2" rubber line after the T and the next 5 feet of line will travel downhill

- Racetronix sealed catch-tank #CT1L8GS. Plug up breather in cap. Use stainless-steel thick wool as media

- the other ports int eh tank will be plugged and sealed tight, except a 1/2" port with a hose to the air pump. tank to be located in

the drivers side front corner of engine bay.

- will need to adapt 1/2" hose to 5/8" I.D. hose for Ford Pump XR32-9A486-AA, CX-1718_

this pump will be powered by a relay and tied to my ignition fuse block. The Ford pumps have been known to

pull a steady 4 or 5 inches of vacuum and some people have had great luck with them. I think I have to solder

some wires inside of it and take out the foam guts too. If these pumps fail, they dont lock-up which means

the wheel can spool and keep venting crankcase pressure until I notice the issue. pump to be mounted either directly

underneath catchcan, by front turn signal of drivers side or passenger side . not sure yet.

- exit hose (5/8" I.D.) will come off of the pump and point to a safe spot under the center of the car in case of

massive oil discharge.

A few quick questions:

- does the height of the components really matter that much. I could see it being more of a factor if it was a vented breather style can or a catchcan only, but should I be worried about any of this uphill/downhill nonsense if I have an electric motor pulling vacuum on it?

- Longer runs of hose is better right, allows hot oil mist to cool to oil droplets in the hose along a long distance? In total it looks like about 5.5 feet of distance from pass valve cover to travel to the location where I want the catch tank.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 02-21-2024 at 10:03 PM.

|

|

|

02-22-2024, 11:02 AM

02-22-2024, 11:02 AM

|

#623

|

Join Date: Jul 2011

Location: harmony, nj (phillipsburg)

Posts: 517

|

Quote:

Originally Posted by IROCZman15

It has been a while, but I drove the car a bit into December, and it has sat untouched until a week ago. I have a list of projects to tackle on it in the coming weeks, and one of them is to finally do something better/different with my crankcase pressure and annoying oil leaks.

For the past 4 years that this engine has been in the car, it has somehow survived on the terrible setup of having a breather in the passenger side valve cover and an elbow with a 3/8" I.D. hose coming out of the drivers side valve cover and necking down to a tiny 3/16" I.D. vacuum port built into the sniper throttle body. Time to be done with that.

Current:

Best solution would be a mechanical belt driven vacuum pump and all that goes with it, but I don't have the $1300 for that plus then I would want to redo alternator, power steering pump and brackets, which is far beyond budget. Research showed that electric vacuum pumps can be hit-or-miss and a wide range of success-fullness on street/strip cars, but I am going that route. I am going to use a catch can also, and hope to keep the price tag for the entirety of the project around $250. I currently already bought the catch can $105 and an ebay Ford pump $62 and some cheap 1 way check valves, so I think its realistic. This also doesn't have to be the best configuration possible either, thats not my goal; it just has to do better than my existing setup.

Here's the plan that I hop to make work for my car.

- baffles in both valve covers (done)

- both valve covers to get a rubber or rubberized plastic 90* elbow that fits in the 1.22" valve cover hole

- a rubber line off each valve cover (3/8" diameter or 1/2" diameter hose) angled slightly uphill to a Tee-Y

- a 1-way check valve in the 1/2" rubber line after the T and the next 5 feet of line will travel downhill

- Racetronix sealed catch-tank #CT1L8GS. Plug up breather in cap. Use stainless-steel thick wool as media

- the other ports int eh tank will be plugged and sealed tight, except a 1/2" port with a hose to the air pump. tank to be located in

the drivers side front corner of engine bay.

- will need to adapt 1/2" hose to 5/8" I.D. hose for Ford Pump XR32-9A486-AA, CX-1718_

this pump will be powered by a relay and tied to my ignition fuse block. The Ford pumps have been known to

pull a steady 4 or 5 inches of vacuum and some people have had great luck with them. I think I have to solder

some wires inside of it and take out the foam guts too. If these pumps fail, they dont lock-up which means

the wheel can spool and keep venting crankcase pressure until I notice the issue. pump to be mounted either directly

underneath catchcan, by front turn signal of drivers side or passenger side . not sure yet.

- exit hose (5/8" I.D.) will come off of the pump and point to a safe spot under the center of the car in case of

massive oil discharge.

A few quick questions:

- does the height of the components really matter that much. I could see it being more of a factor if it was a vented breather style can or a catchcan only, but should I be worried about any of this uphill/downhill nonsense if I have an electric motor pulling vacuum on it?

- Longer runs of hose is better right, allows hot oil mist to cool to oil droplets in the hose along a long distance? In total it looks like about 5.5 feet of distance from pass valve cover to travel to the location where I want the catch tank.

|

leave the pcv hose intact to the sniper, leave it that way for street or add or drill another bigger port in the intake for vacuum (spacer under sniper with a larger vac port). dont worry about uphill downhill etc.

run the e vac pump only at the track spraying nitrous. thats probably when most of your leaks are occuring. my motor is tight with pcv/street driving/catch can, but when spraying it pushes oil. im going the e-vac pump for track use only. they dont really survive in continuous use on the street. so mine is being set up to be easily swapped from street with pcv/can to track with can/e-vac pump

__________________

1994 Firebird Formula - Injuneer's car - NEW PB 9.90 @131

2021 Charger Scat

Wrench/driver 94 Camaro Ellwein 385/D1SC/CPT 4l60e/9" slow pile

Last edited by townsend; 02-22-2024 at 11:04 AM.

|

|

|

02-23-2024, 09:14 PM

02-23-2024, 09:14 PM

|

#624

|

Join Date: Sep 2008

Location: Howell,NJ

Posts: 537

|

I run the gm electric pump on my car, I had to increase voltage to 24 volts in order to pull 7hg in the crankcase. I don't know about the ford pumps but if you need more hg a $20 amazon volt booster will get you there. You don't need both valve cover hoses it's not going to pull anymore volume. I would shorten the hoses also, that's a lot of straw to suck through. I run a pressure switch to turn my pump on only under boost from the turbo. For naturally aspirated you could use a vacuum switch to turn on pump. Just my 2 cents.

__________________

94 CAMARO

TURBO 3.5 LITER

12.573 @ 107.29 1/4 MILE

8.021 @ 86.38 1/8 MILE

BEST 60' 1.781

Last edited by 3.4 grape of wrath; 02-23-2024 at 09:17 PM.

|

|

|

02-26-2024, 09:26 PM

02-26-2024, 09:26 PM

|

#625

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,118

|

I agree about doing the pump primarily at the track like you suggest. I remember reading a good bit of info on that topic via other threads on the holley sniper forums. It intrigues me, so I think once I get this new setup functioning, I will keep a removable pre-assembled pcv and hose to plumb it back to the sniper tbi. Last time the intake was off I debated drilling a port in the backside of it; I will probably end up doing this int he future. With the nitrous plate in there I might only add one other 1/2" spacer, but that could be an option too.

That voltage booster also sounds like a future add on and I especially like the idea of a vacuum switch too. The reason I was going to pull from both valve covers, is because the pcv elbow and attached 3/8" hose is still a pretty small orifice, so it might help a little to pull from both. I can always do some tests and then cap off one side as another test too right?

- Just noticed that it looks like you have almost the exact same catch tank as I am about to use. Any issues with it, do you use a drain on the bottom or have any media inside of it> I'm guessing you pulled out that brass filter inside the cap and put a npt pipe plug in its place for a sealed system?

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 02-26-2024 at 09:31 PM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|

|