|

|

05-06-2021, 07:04 PM

05-06-2021, 07:04 PM

|

#326

|

Join Date: Sep 2010

Location: Hackettstown, NJ

Posts: 165

|

See you tomorrow night at Island. I'll have the 57 there.

__________________

57 Chevy - 210 - 355 SBC-Powerglide-10 Bolt 3:73 Gears - 12.78 best et - 104.78 MPH-street driven

80 Firebird-350 SBC-Turbo 350-10 Bolt 3:42 Gear - 13.69 best et @ 97.52 MPH

96 Buick Roadmaster wagon LT-1 - (DD) for sale

2023 Equinox - wifey's car

22-Ford Maverick-FWD Eco

|

|

|

05-08-2021, 02:31 PM

05-08-2021, 02:31 PM

|

#327

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Great hanging out with you Jerry. You have an incredible wealth of knowledge and experience, so I hope to get to see ya more often. Jerry went runner-up in the gamblers race last night!

I might edit and add stuff to this post later on, but I'll try to get most of it out here now. First thing first, the intake manifold gasket repair held up just fine, no leaks, no loosened bolts, all good. Radiator still has a very slow drip, but Champion is waiting on a hopeful order/shipment from china to ship me out a new one under their lifetime warranty. I'll keep waiting. But the intake is good.

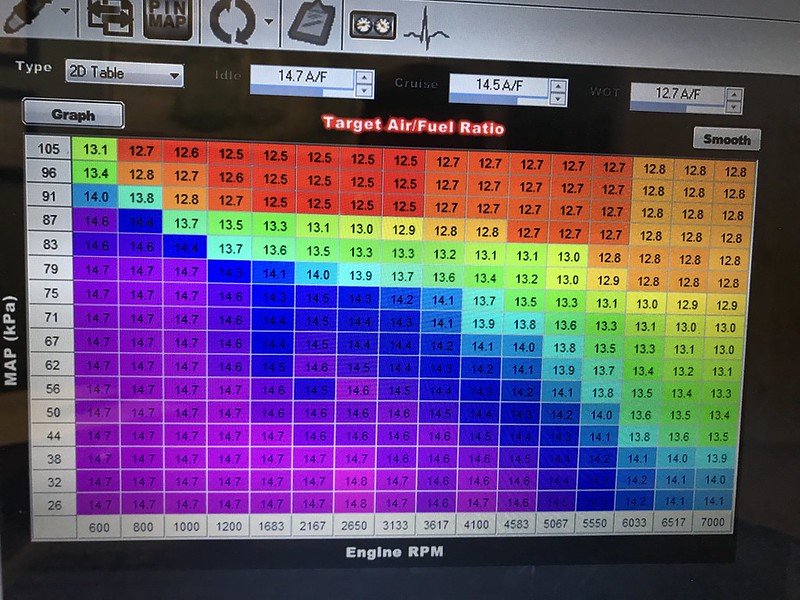

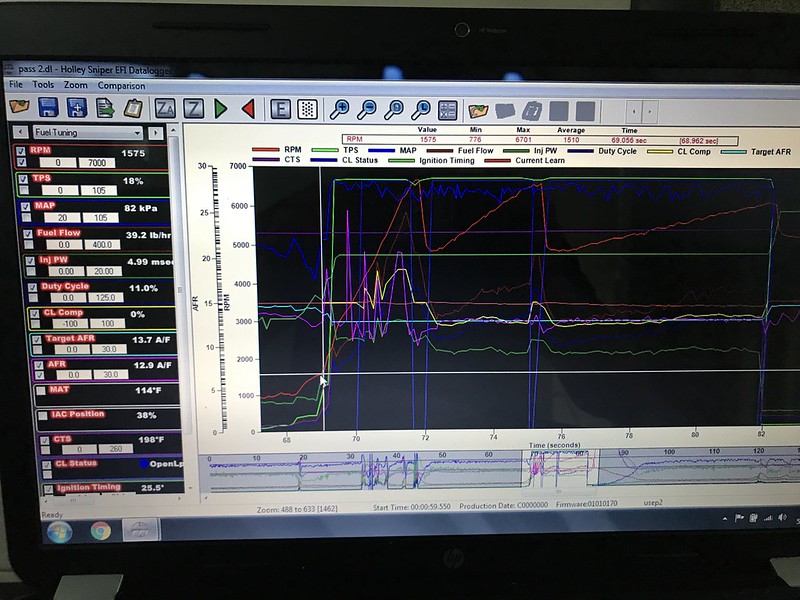

Got 8 runs in. most were garbage due to an issue I am very eager to resolve. Something is happening in Closed loop in ONLY first gear where the CL comp is adding a tremendous amount of fuel and causing the engine to stumble. Pass #2 was good and did not stumble, and after the 6th pass, I said to hell with it and trusted that my base tune was good enough for me to turn off closed loop fuel compensation and just run an open loop (base fuel table) pass. I was still hesitant and expecting it to bog so I was not at full WOT in first gear, but when it took it and didn't misfire, I went WOT and ran a full pass. It actually hit so hard it slightly spun the tires at the launch. Hot lapped it and did the same exact thing just to make sure it wasn't a fluke, and it did the exact same pass, but it spun the tires even more at the launch. So, good news, the base table is great (a little rich) but that means the closed loop compensation is way screwed up and only in first gear. - Details below

** also below, I might be considering getting an inexpensive set of front 90/10 drag struts to bolt on if I am going to be doing a drag race event. Unless I am missing something, Its only two bottom bolts, a top nut, and a brake line bracket to remove the strut. Something I can swap in 15 minutes while putting the drag wheels on or off. Reason I am considering this, is because if I am spinning the tires now at NA power on the open loop launch, there is no way a koni yellow strut will transfer the weight properly to the back on a nitrous launch. Even on the softest and loosest koni strut setting, you have to use 2 hands and your whole body to try to lift the front of the car up at all. With a 90/10 I've seen guys be able to bounce the car like a toy. So I am considering this, and would swap them off for street and autocross use of course.

Did not get any GoPro footage, didn't' have time to play around with it. Some of my dashcam videos are corrupt, so I only have recordings from 4 of the 8 passes, and I did not include any rear-camera video footage. Also, Did not remember to check the DA after the first 3 passes as I was so scatter-brained about what the heck was going on with the 1st gear fueling. The Da started around 800 and was pretty much down to 600 or so by the end of the night. It was humid and rain was expected. I kept the drag radials at 19.5 and 19 psi all night, and the shocks stayed at .05 out of 5 on the front koni struts, and 2.5 out of 5 on the rear koni shocks.

Pass 1: no video

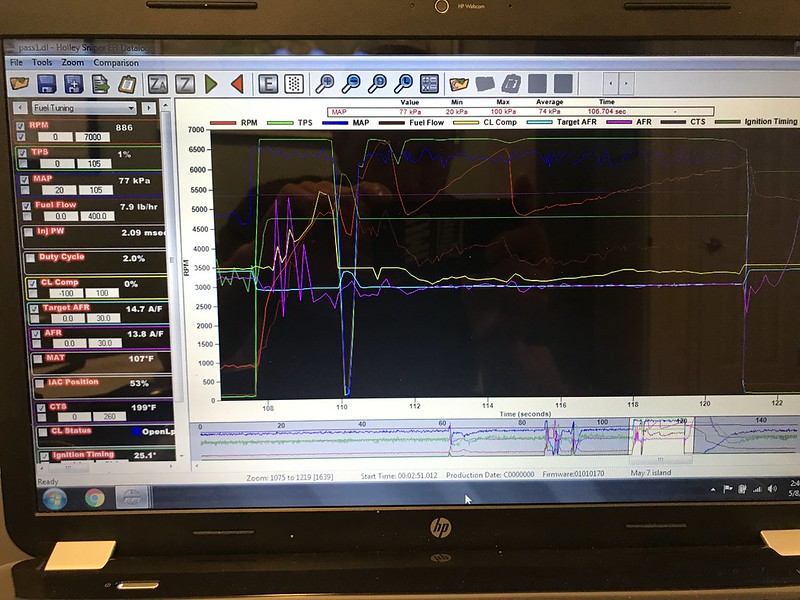

4 second burnout. launch from idle at 878 rpm. converter flashed low at 2543 rpm and then the first bog/misfire of the night happened right around 3,000 rpm. see the jagged pink line in the graph, thats my actual AFR.The pink line should be super super close to the light blue line (target AFR). And the rising yellow line above it is CL comp, which is what the computer is adding to my base table to try to get the AFR to where my target (12.7:1) afr wants to be. CL comp added 56% !!!! before I got out of the throttle, pedaled it, and then revved 1st gear to 6,723, second gear to 6,524 and finished the run at 6,065. This "bog" in first gear has happened earlier this year at TnT . My buddy John was there with me and we looked at the tune file (GCF file) and can not make sense of why it would be adding THAT much fuel).

Pass 2 : no video5 second burnout. footbrake launch at 1,661 and flashed at 2,668 rpm. No bog! Shifted 1st at 6,461 and dropped to 4,803 shifted 2 at 6,532 and dropped to 4,853 and crossed the finish line at 6,128 in 3rd great. An optimal pass. felt good. full pass, no blips, bobbles, or issues. The pink line is very close to the light blue line, AFR was good, nothing weird. the yellow CL comp line had very low single-digit fuel compensation numbers. I was happy, and the 11.94 at 114 seemed promising because thats where this car has been happy before.

Pass 3: video with audio of the bog

https://www.youtube.com/watch?v=ryNndIXpspk

A 6 second burnout, and footbrake launch right at 1,598 rpm. After the converter flashed at 3,050 the CL comp (yellow) camein hard and added an INCREDIBLE amount of fuel... actually up to 76% additional of my base table for a total of 391 lbs/hour of fuel at that point. I shifted during this while getting out of the throttle, pedaled it, and got back into it for the rest of the run, even shifting 2nd very early at 5,691. Getting frustrated after this run. John and I were looking at the base table and CL comp limits and parameters, Nothing is activated that we can see that should require this much fuel compensation to be coming in at these rpms in 1st gear. Even in 2nd and 3rd gear, the table doesnt use this much fuel at these rpms.

Pass 4: video with audio

https://www.youtube.com/watch?v=z7hvy74ORNA

5 second burnout, launch at 1,769 and flash at 2,755 rpm. It actually spun the tires at the hit, you can see the car rotate sideways to the left as the tires are spinning just a touch. Yet, again, a "lean spike" and CL comp comes in hard, ramping up the fuel compensation into the 50%and60% value from my base table. I get off the throttle, back on it, shift and make another confused trot down the dragstrip. The yellow line should not be like that, no way, not at all.

Pass 5: video

https://www.youtube.com/watch?v=o_u0wmqzATA

5.5 second burnout. launch at 1,530 flash at 2,602. stumble, misfire, "overfueling", pedal it, abandoned the run.

Pass 6:

4 second burnout. 1,719 launch and I actually cant tell where the converter flashed on this log. same stumble, bog, CL comp way up, got out of it and abandoned the run.

*** Please don't think that I was just continually running the same tune trying on hopes and dreams that it would resolve itself... I was adding in fuel to the base table in the areas that it was CL comp adding, in hopes that it would be sufficient.* BUT there was no way I was going to add 60% more fuel to those areas. that number does not make sense. Again, I wasn't that dumb to just keep on running the same exact tune. Adjustments were made to the closed loop tunes in between runs.*

.

Got very frustrated, and John and I decided that If I am comfortable with my KNOWN good base table numbers (from al the track stuff last year) I can just make an open loop pass and turn the Closed Loop fuel compensation off, as well as the learn data. So basically, just fueling the engine off of the base table and the base table alone.

Pass 7:

https://www.youtube.com/watch?v=gmRynW_u-kw

(OPEN LOOP) 4.5 second burnout. Footbraked a little low at 1,210 and because of the recent bad launches, my foot was hesitant to go full wot. the light green line on the Datalog shows I was at 80%-84% throttle for all of fist gear, BUT THERE WAS NO STUMBLE OR BOG. I must have been so stunned, that I shifted way early, at 5,530 rpm. I then went to 110% wide open throttle and shifted 2-3 at 5,691 rpm (way early) and finished the run at 6,115 rpm. I was ecstatic, surprised, and impressed. I noticed the AFR numbers were a tad rich while I was making the pass (12.3:1) but I had NO time to make a change, because they were closing the lanes in 2 minutes.

Pass 8; (Open loop) Drove directly back into the staging lanes, and I think I was the very last car down the strip that night. launched at 1,862 rpm and a flash at 2,478 rpms. I was still hesitant to go FULL WOT in all of 1st gear and all of 2nd gear (green line). No bog in 1st gear at all. The base table is good, and open loop is good, no input from CL comp involved. Shifted 6,549 and 6,294 under about 87% throttle and then went WOT in 3rd gear.

Hungout with John a little bit more (he has a 3rd gen silver TA that was racing with me 3 weeks ago. Needs a clutch replacement. His car runs 11.0 and 11.1x Goal is 10.9 next time out. Lives in woodbridge, very cool guy. Put the car back into a known good closed-loop tune and drove home.

TOTALLY CRAZY INSANE LEARN TABLE NUMBERS?!?!

base table of the day:

[

any ideas what in the heck is going on in first gear with that HUGE fuel compensation?

Also, thoughts on a set of 90/10 front struts for drag days?

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 05-08-2021 at 05:40 PM.

|

|

|

05-09-2021, 09:30 AM

05-09-2021, 09:30 AM

|

#328

|

Join Date: Oct 2008

Posts: 586

|

GO to basics. While it will be touch to see now since you drove it, what did the plugs look like? Is 1 cylinder spark/ fuel , ect, not happy? This kit only has 1 O2 sensor? If so switch it to the otherside. This will tell if 1 bank is acting up. You may not feel it.

Other idea, and its semi far out, is exhaust scavenging. You could be scavenging too much and pulling the incoming charge out of the chamber directly into the exhaust resulting in a lean condition. Thus why its is adding fuel.

Is your ECU setup to turn CL off after a given TPS % or is it CL all the time?

You said this was only in first gear?

PS .. this is what happens when you drive by w/o stopping to say Hi. You stay forever 12's.

Last edited by TaKid455; 05-09-2021 at 09:31 AM.

|

|

|

05-09-2021, 01:26 PM

05-09-2021, 01:26 PM

|

#329

|

Join Date: Sep 2008

Location: Hackettstown, NJ

Posts: 1,643

|

That coolant temp sensor you swapped locations isn't just a display, right? It's part of the Sniper EFI? It's real possible that the 'tune' is now off due to it seeing much higher coolant/engine temperatures.

__________________

1998 Z-28 - SLP lid - Ported TB - LS6 Intake - Dynatech SS headers/Catted Y - Magnaflow Exh - 3.42 - Yank SS3600 - UMI weld-in subframe connectors, Adj LCA, Adj PHB, Q1A TA - Bolt-in Relocation Brackets - Strano springs - Koni shocks - 17" C6Z06 wheels - 326HP/335ft-lbs - 12.35 @ 110.41

Quote:

Originally Posted by Blackbirdws6

I can appreciate a dream but this person needed some real friends.

|

Last edited by The_Bishop; 05-09-2021 at 01:26 PM.

|

|

|

05-09-2021, 02:09 PM

05-09-2021, 02:09 PM

|

#330

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Sounds a lot like a dead or dying wideband sensor to me.

Hopefully you have learn function off right?

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

05-09-2021, 07:18 PM

05-09-2021, 07:18 PM

|

#331

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Thank you all for the replies and ideas. Any help is much appreciated.

Larry: yes just one O2 sensor for the holly sniper. Unfortunately my DynoDon's headers only have a bung for the O2 sensor on the drivers side. It is in a good spot, but it is unlikely I will be drilling and welding a bung to the other side. I plan to remove these headers in the winter for a set of bigger long tubes, so I don't want to modify a good set of headers that will soon be for sale. I did not check plugs that night at the track, and as you mentioned, I did drive home after so the plug readings would be skewed.

-the fuel charge scavenging theory is something I have never even thought of. I see what you are saying. That would be WILD if that were happening. Wouldn't it be more pronounced at higher rpms such as at the top of 2nd or 3rd gear though instead of such a short period of time mid-rpm in 1st gear?

- The ECU Closed Loop Parameters can be adjusted by me. They can be left on al the time, off all the time, or pretty much anything in between. there are options for if I want it to deactivate at a certain Throttle position, rpm, etc. However, on my first 6 passes, I simply left Closed Loop (and Learn) on because I feel safer that it will make the right adjustments and save the engine if something went awry in the base tune. AS it turns out, this is exactly the opposite of what happened, and the closed loop feature went wild adding fuel, but if it needed to do it for some unknown reason, it did the right thing. I just then need to find out "what" caused it to add fuel.

- And yes, this has only ever happened in 1st gear and only at the track. Not during street driving, heavy street driving, burnouts, or anywhere else. Only 1st gear at the track. Once during my early April track day, once during the April 18th track day, and then 5 times (out of the 6 closed loop passes) from this weekend. Bizarre

-Ah man, every single time I drive past the shop, I look to see if there is any activity in the parking lot and if So I would instantly take a detour and say hi. But I don't want to be that annoying fella who just stops by randomly and barges in, so usually I just drive past. I can stop by next time!

Bishop: yes, the coolant temp sensor that I relocated is not jsut for data display on the handheld. The sniper uses it for lots of tables. However, prior to heading to the track I went out and bought one of the highly recommended accurate Standard TX3 coolant temp sensors. I wanted my tables and tunes to be just as I have had them for the past 14 months. So I installed the NEW temp sensor in the exact spot on the intake that the holley used to be in. I left the holley one in the passenger side cylinder head so that I did not have to drain coolant. I unplugged the connector from the one in the head and moved it to the new one in the intake. Basically, all temperatures were dead spot on all night at the track. I also don't pull away any ignition timing based on temperature until way higher temps from where it was running on Friday night. I do appreciate your thought process, but I thought of that all ahead of Friday and there should be no correlation between the CTS and this bog issue. Also, remember, this bog happened in early april and mid april when the CTS was untouched.

Matt: So, I am partially thinking it might be oxygen sensor related. I have read countless times about the Holley O2 sensors failing, but the symptoms people describe don't seem to match mine. Lots of topics on this at the Holley forum, and most I have read just have a sensor go pegged dead lean at 35 or something. I don't have that. After those two open loop passes I was confident in the base table and knew that the engine wasn't hurt or anything. Nor the trans. So, to test that idea that an O2 sensor was acting wacky, I loaded up a known good (non-drag race) tune and drove home, eyebaling the AFR readings the whole time. And, the whole time, the afr and o2 sensor did nothing that even suggested it was problematic. I drove 30 minutes, in all 4 gears on the way home, even with some moderate pulls on rt 80 just to run the engine and efi through its paces. Its fine, never bogged, never did any crazy afr readings.

feel free to keep the advice coming. Would love to get this issue resolved really soon, as I am due to bring the car for the roll bar install in a few weeks and would really like to have an 11.7x pass under my belt by then.

__________________

1987 IROC-Z - modified

|

|

|

05-09-2021, 07:56 PM

05-09-2021, 07:56 PM

|

#332

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Another thought, in theory if you were losing fuel pressure it would read lean, and CL would try to dump fueling in there. Or a injector not firing as it should.

And since you had spark plug wires and headers off, def make sure you have all cylinders firing and no exhaust leaks prior to WB.

What percentage do you have CL set to? IMO, if the tune is solid, you should have learning turned off and only allow small percentage CL changes.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

Last edited by LTb1ow; 05-09-2021 at 08:02 PM.

|

|

|

05-10-2021, 09:07 AM

05-10-2021, 09:07 AM

|

#333

|

Join Date: Oct 2008

Posts: 586

|

"Wouldn't it be more pronounced at higher rpms such as at the top of 2nd or 3rd gear though instead of such a short period of time mid-rpm in 1st gear?"

It would be consistent in each gear. RPM may vary but the affect would still present itself.

As stated, something is telling the ECU its lean or has an extreme temp cold or hot. ECT or IAT sensor.

You could have a wonky O2, but one would presume it would be consistent regardless of gear.

Look through your IAT, O2 & ECT data. You are looking for a blip leading up to & including the problematic area as the issue is only occurring for a brief.

|

|

|

05-10-2021, 02:41 PM

05-10-2021, 02:41 PM

|

#334

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

A couple questions.

1. How much fuel did you run in the tank? You're getting what looks like a nice little lean spike on the initial hit which calms down through the run. Did your prior logs show this?

2. Are you logging fuel pressure and system volts? I'd be curious what those values look like through the run.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

05-10-2021, 07:44 PM

05-10-2021, 07:44 PM

|

#335

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Matt:

Yup. I am very meticulous about bolt checks and triple checking that everythign is tightened down after a heat cycle or two. That's kinda built into who I am, and I have a pre-race event check list where I make sure I do my specific bolt checks, headers and exhaust has always been on the list. I agree wit hyou about if I was losing fuel pressure it would read lean. However, al that happens is usually a lean spike and then the CL comp sees this little spike and goes crazy adding tremendous amounts of fuel. There is indeed somethign interesting/confusing I noticed on pass #5, which I will post below, because the AFR was RICH at 10.0 and hte CL comp was going nuts adding fuel anyways. See below. I agree with you about limiting learn and CL comp amounts. I had everythign locked down pretty good last year to where the CL comp could only take away 10% of fuel and could only add 25% fuel across the whoel table on all of my drag-race based tunes. This seemed to work out well. I was told that this is wise, but a smarter decision would be to have the Cl comp be able to add 100% but only take away about 10-20%. Reason being, in case a mechanical problem actually really did happen, the computer could save the engine by adding fuel quicker than I could come off the pedal or turn off the engine. That made sense to me, but it might have opened the floodgates (literally) for the CL comp to start doing whatever it wanted to do, including adding massive amounts of fuel for an unknown reason.

.

Larry: yes, glad I wasn't thinking incorrectly about that aspect of it. So, since I see almost NO Cl comp added at the top of gears 2 and 3, especially while at WOT, I am pretty confident that it is not a fuel system or fuel delivery issue. Some of the guys on the Holley forum are telling me its fuel system related, and I will investigate this aspect as much as I can, but I am still thinking it is tune, ecm, sensor, related. Same thinking as you regarding that O2 sensor being wonky. I would think that in the course of the last 5 weeks of driving the car, 3 drag race days, and whatnot, the O2 symptoms would be more prevalent than just simply acting up at Island dragway in a drag launch. I would see all sorts of wonky readings at various times. basically my learn table would look insane after simply driving the car a distance (like to and from Englishtown a few weeks ago), yet the learn table was super clean and low numbers, low enough that I never even decided to transfer the info to the base table. I am going to do my best to carve out some time to really dig into the datalogs and turn on every available sensor/parameter in each view-page and see if I can find this blip. If it is there, that will be the smoking gun.

Brian:

I had a completely full tank. The Shell gas station just half a mile away from Island Dragway is now open and I fueled up the whole tank with 93. I always make sure I have a full tank or as close to it as possible. I've never been of the thought that I can save a few pounds of weight and run a half tank of fuel. This became apparent to me back in 2017 at the Optima Street-car challenge when I was doing autocross and speed stop laps and my tank was low and for sure it was starving the old engine. I have always seemed to have either a rich or a lean spike at the hit whenever I launch. Since I am always leaving either at idle or a 1500-1800 rpm foot brake, and it is TBI so no injectors per cylinder, it has done both lean and rich spikes. I spend a lot of time refining the base table in this area, and I can only do so to a certain extent, without it getting screwed up during the burnout when it hits those same cells in the base table. Also, sadly, the Sniper software can not log fuel pressure. My mechanical analog gauge can, but that is under the hood. Testing of it over the winter showed it to be at 61-62 psi and the sniper's internal regulator likes fuel pressure at 59.5 psi, but they say give or take a few psi is fine. As for volts, my Holley reads low. It is wired directly to the battery with 10 gauge wire. When the battery reads 12.2 and the car is off, the sniper reads 11.9 or 11.8. On the datalogs, the battery trace is very consistent, yet numerically low at 13.3 volts...but it has been this way for every datalog in the last 14 months. The alternator is a powermaster unit and it is only a few years old. If you guys would like I can enable the battery trace on any datalog and show ya that it only drops by 0.1 and at most 0.2 volts at the hit of the throttle.

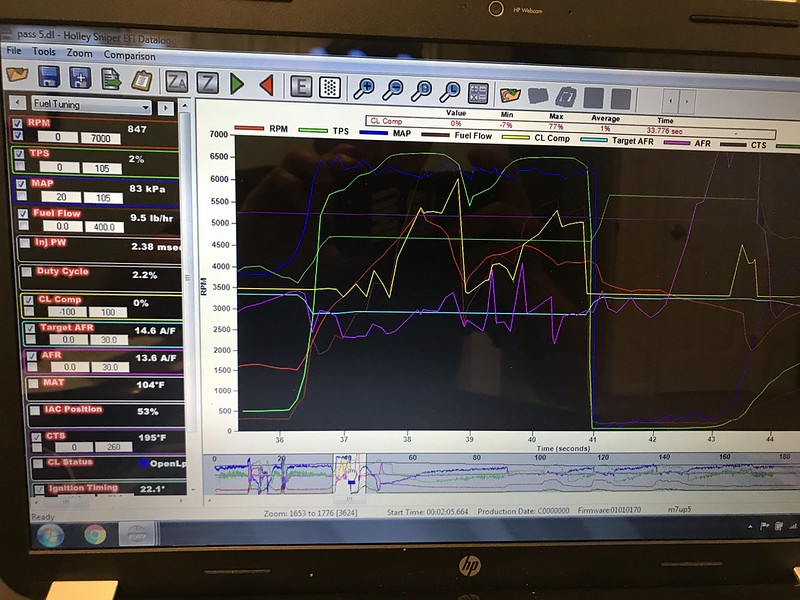

Pass 5:

This would stink if it was a failing injector or the like. Yet, I keep coming back to the clean Open Loop datalogs. But last night I did take notice of something on a closed loop pass, Pass #5, between 36 seconds & 39 seconds, which is when I launch.

What do you make of this situation:

- I had a fully cleared out Learn Table, all 0.0 numbers on there.

- Base tune is very solid and has been used many times prior.

- I footbrake launch from 1530 RPM and AFR goes rich, never does it spike lean.

- It goes immediately into Closed Loop and gets rich to about 10.0 AND then at the same exact time CL Comp comes in ADDING fuel. First at +4% then at +14%.

- AFR somehow gets less rich at 10.7, but the CL Comp is now +23%.

- AFR finally gets to Target AFR, but now the CL Comp is at an insane +57%.

- I feel the engine bogging, and I get out of it just at the same split second that the AFR now finally gets actually lean, at 14.7, and at this moment the CL Comp is +77%.

Why would CL Comp add tons of fuel if it's already reading a rich mixture? If as you said, fuel pressure is not at 60, well maybe that could so it, but is there a chance this is all an intermittent Closed Loop EFI problem and not a mechanical issue? There were no lean spikes until I got off the throttle. That makes no sense whatsoever to me. Anyone?

Datalog Screenshot:

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 05-10-2021 at 07:55 PM.

|

|

|

05-11-2021, 07:11 AM

05-11-2021, 07:11 AM

|

#336

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Check any of the modifier tables, perhaps they are now hitting cells that the new ECT allow?

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

05-17-2021, 07:22 PM

05-17-2021, 07:22 PM

|

#337

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

I can get into more details about the 1st gear bog if anyone would like to discuss that further. Spent lots of time looking at past datalogs and examining the VE table and modifier tables. Also checked as much mechanical stuff as I could (fuel pressure gauge reads 62psi and barely takes a dip when engine is revved, all exhaust bolts tight, all injectors are spraying equally, zip-ties the notoriously unreliable injector connectors to stay locked in, checked a few plugs, etc). Did some test driving, the car acted better, but the true test would come on the track.. which I went to yesterday for my last Drag race day until probably the Fall of 2021. Also in the tune, I took away the ECU's ability to be in closed loop all the time. One of my thoughts with this bog, is that the ECU is spiking rich, lean, rich lean so quickly through 1st gear it cant make up its mind about what to change quick enough. So for the first two passes, I kept the ECU in open loop until 4,000 rpms. For the second two passes, I kept the ECU in open loop for until 4,500 RPMS. The car didn't bog or stumble at all in first gear, but there was usually a very quick spike in the AFR trace. I've been told that on initial "tip in" with no air filter and a TBI, I should expect a spike/blip. So by keeping the ECU in open loop past this point, it avoided making ANY changes, and it really only came in to adjust my CL fuel compensation when I was higher in the rpms in 1st, 2nd, 3rd gear. I'm happy about that.

Also, I decided to buy the most inexpensive front DRAG strut available to see how the car lifted at launch. I bought the Lakewood 90/10 Drag strut. I know there are adjustable struts for big $, but I do not have the budget for those. These lakewood's do come up quick. I filmed a few short videos of them compared to the koni yellows when I did the strut swap. I have yet to edit or upload those videos, but I will do so in the next week. The lakewood 90/10 drag strut is not as "treacherous" on the street as some people have made it seem. The car was a bit floaty on the road, but I also had no front sway bar, skinny front tires, and the 90/10s. The did help the car lift and transfer weight better, but I launch at such a low rpm, that They aren't able to do their best job just yet. more on all that in the future.

Front tires were at 43 psi all day and rear tires were at 19 psi all day. Lakewood non-adjustable 90/10 struts up front and the Koni yellow shocks in the rear were at 4/5 all day which is medium-tight.

-fun note, every car in the lane next to me all 4 passes ran in the 9 second zone, so I felt like a total chump!

Pass 1:

Did a 6 second burnout, and now I am getting used to shifting into 2nd gear during the burnout, before I would just do 1st gear. My buddy John was there and we decided to see if I could get a little more RPM off the launch by not only going heavy on the foot brake, but also using the E-brake. The car began to roll just as I got close to 2,100 rpms and almost rolled the beams, so I just left. Datalog showed I went WOT at 2,228 rpms and the converter flashed at 3,015 rpms. No BOG ! Shifted 1st gear at 6665 and landed in 2nd gear at 4,732. It was right after the shift, when I saw the red light on the dashboard, and realized that I had not fully put het E-brake back down!! What a dope. So I fully released the e-brake, shifted 2-3 at 6,530 and landed at 4,870 rpms. Crossed the line at 6,214 rpms. Entire run was at 34 degrees of timing and target afr was 12.8, DA was 1365, Temp was 71 deg, and Humidity was 42%.

video: https://www.youtube.com/watch?v=eZJG5RGI_sw

Pass 2:

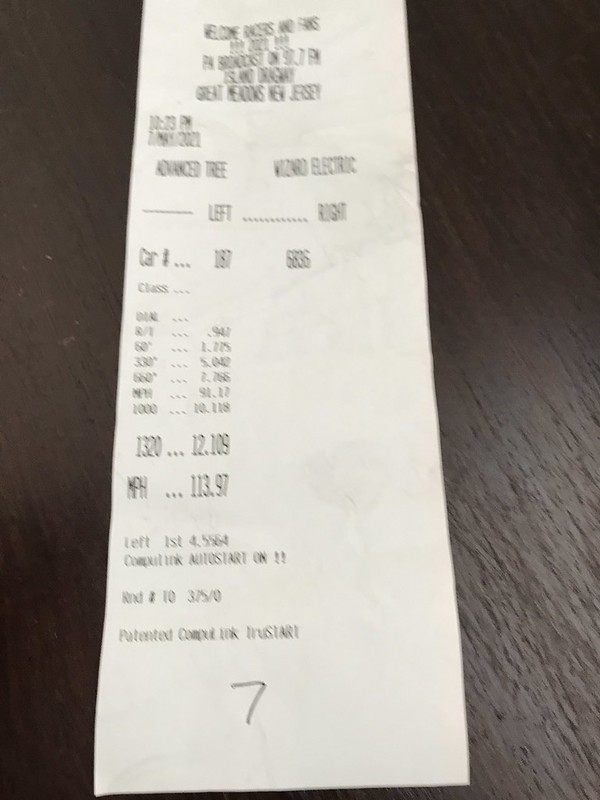

Another 2-gear, 6 second, mid rpm burnout, just enough to get the tires to smoke a puff. Footbrake launch at 1575 using the ebrake, and I put it down fully this time. Converter flashed at 3,018 rpms and I shifted out of first gear at 6684 rpms and landed in 2nd gear at 4870 rpms. Shifted 2-3 at 6596 and landed at 4888 rpms. Crossed the line around 6,100 rpms. Target afr was 12.8, Timing was 34.0 deg, DA was 1286 Temp was now 70 deg, and humidity 44 deg.

video: https://www.youtube.com/watch?v=5D2oIybKBpw

-this video John filmed finally gives me an idea of how the car leaves the line. I can try to view itin slow-motion, but I can't see any tire spin, rear body squat, or anything bad.. it just leaves from such a low rpm that it takes a little effort to get up-and-go...

Pass 3: (quickest pass ever, so far)

Mid rpm 2 gear burnout for 5 seconds. Launched from an idle this time at 933 rpms and the converter flashed at 2950 rpms. Shifted out of first at 6,545 and landed at 4841 in 2nd. Shifted 2-3 at 6593 and landed at 4910. Crossed the finish line at 6,202 rpms. I had bumped the timing up one degree to 35.0 deg, and we also leaned out the target afr a little bit to 13.0. DA was 1174 temp was 68 deg and 48% humidity. In the lane next tome was my friend Kevin who runs high 9's in that awesome Trackhawk.

video:

https://www.youtube.com/watch?v=8M__Jokh5nU

Pass 4:

6 second, mid rpm, 2 gear burnout. Launched basically at idle again since my 60 foot was great last time. Converter flashed a little low this time, at 2812 rpms. 1-2 shift was 6736 landing at 4,876 and the 2-3 shift was 6,552 landing at 4,847 rpms. Finish line rpm was 6,230. Target AFR was 13.0 and ignition timing was 35.0 I did not remember to check weather data before this last pass.

video: https://www.youtube.com/watch?v=1pGTGxinJOE

So overall, man, I was really realllly hoping for a timeslip with an 11.79x et on it at around 117 mph. I am o.k. with the timeslip from pass 3 which was 11.8000 at 116.19 mph. I do think it is possible, but I will have to wait for a while as I switch the car over to autocross and car show mode for the summer months. I am also set to have the roll-bar installed in June.

After getting home, and as always keeping an eye on the high oil pressure, I removed the drag wheels to give them a wash since they will be going away for a few months while I switch to autocross. At this time I noticed a crack in the hub of the drivers side front Jegs SSR wheel. WOW. scary. I removed the passenger wheel and noticed a similar crack. Wow, extra scary. I have never ever, not even once, used an impact gun to tighten these down. I always, always, always use my mechanical torque wrench. I bring them to 90 ft/lbs each, and then bring them to 110 ft/lbs each. How the heck could these have both cracked? I do think they are salvageable, and I am going to research what to do. Cast aluminum, so I am thinking the crack can be opened up to its deepest point, welded with aluminum filler rod, and buzzed down. Thoughts?

Drivers side:

Pass side:

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 05-17-2021 at 09:14 PM.

|

|

|

05-18-2021, 03:36 AM

05-18-2021, 03:36 AM

|

#338

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Wow that's more than a little scary. I assume the hub size isn't too tight on the wheel? Anything on either hub that would somehow cause it to bind a little? I wouldn't attempt to get that fixed personally and contact Jegs to see what they can do for you.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

05-18-2021, 06:53 AM

05-18-2021, 06:53 AM

|

#339

|

Join Date: Nov 2007

Location: Jackson, NJ

Posts: 1,724

|

You can absolutely weld them up, that isn't an issue. I'd see about a warranty with Jegs as well. Glad you noticed them before it turned into a bigger issue

__________________

1983 camaro- Scrap

1988 camaro- Also scrap

'05 Silverado- You guessed it, scrap

1988 TRX 250R- Ported w/ high compression on 110 octane- Out 60' your LT1

Jersey Shore Street Car Takeover (JSSCT) Founder

Quote:

Originally Posted by LS1ow

and once i get PHB, what do i ajust it too?

|

Quote:

Originally Posted by Jersey Mike

Seven.

|

|

|

|

05-18-2021, 09:20 PM

05-18-2021, 09:20 PM

|

#340

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Hubs on the rotors are clean and clear. In fact, from time to time I clean them and then I smear a little coat of silver anti-sieze on the hub part of the rotor hat too, as it helps with removal on some of my other vehicles where the wheels aren't removed all that often.

The hole in the wheel hub has plenty of clearance on the hub and dust cover area too, nothing too tight, but not sloppy loose either. Whenever I install any wheel on any car, I sit down under the wheel opening, roll the wheel into my lap, and use my legs to lift the weight of the wheel into place, and HOLD it there while I hand spin on the lug nuts. I used to use an old school speed-wrench too, and then I would get out the torque wrench. Fr about 20 years now, My process has never been problematic for wheels on any of my vehicles or others, so it is weird that very similar cracks developed on two wheels in a short timeframe. I had both wheels off the car just the day before, while I was installing the Lakewood 90/10 drag struts. Not saying that i examined the backside of them, but I did not see any signs of cracking then.

My rule of thumb for the past 20+ years has been that steel wheels get torqued to 80-100 foot lbs, and aluminum wheels 100-120 foot lbs. My original aluminum iroc wheels, my eagle alloy aluminum ones, my boze forged aluminum ones, and these jugs SSR wheels were all always torqued to this 100-120 spec. Looked at the JEGS SSR wheel tech sheet and they call for an astoundingly LOW 40 foot pounds. I'm sorry, but I could not bring myself to drive the car for a moment if I only torqued my front wheels to 40 foot pounds.

- scroll down to the "instructions tab" on this website and view instructions pdf. https://www.jegs.com/i/JEGS/555/680251/10002/-1

and step #5 says approx 40 foot lbs.

weird

Anyways, I agree with wretched, I think they are fixable. Either by a professional wheel shop or by a good welder who can weld aluminum. Not just fill it, but pre-heat the aluminum wheel, grind open the crack, and structurally repair the crack. I am going to call jegs in a day or so, but I am assuming that since I am not the original purchaser of the wheels, they will just tell me, hey, nothing we can do for ya. I will make the phone call though. I really like the wheels and want to keep them for a few more years until I can get my dream drag race wheel/tire setup. Centerline Convo-Pro skinnies and rears. One day, one day.

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 05-18-2021 at 09:24 PM.

|

|

|

05-19-2021, 07:02 AM

05-19-2021, 07:02 AM

|

#341

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

So are you going to torque them to 40 or something else?

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

05-19-2021, 11:05 AM

05-19-2021, 11:05 AM

|

#342

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

No way would I be comfortable torquing them to only 40 foot pounds. I’ll get em fixed and maybe torque then to 80-90. 40 seems so low. I’m no metallurgist or science guy but I don’t know how 40 would be tight enough on an acorn lug nut on wheels that turn, street drive, and are used as actual wheels

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 05-19-2021 at 11:05 AM.

|

|

|

05-19-2021, 11:13 AM

05-19-2021, 11:13 AM

|

#343

|

|

Meet Coordinator

Join Date: Jan 2008

Location: brick/pt. pleasant beach

Posts: 19,341

|

Are you sure the acorn is seating into the wheel and not bottoming out? I think I remember jegs and summit having issues with Chinese knock-off wheels.... looks like there is damage opposite of the crack, don’t know if it was existing though

|

|

|

05-19-2021, 03:17 PM

05-19-2021, 03:17 PM

|

#344

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Good point. I’m pretty sure that they aren’t bottoming out but I’d really have to check. I know I have always had to use a 1/4” spacer between the rotor and wheel to deliver the clearance from the inner rim-face to the caliper fins. This I researched before buying the wheels and I found this answer on the corvette forums ( I run a C4 HD brake setup) for those who use the JEGS SSR wheel. I tried without the spacer on the first day I had the wheels and they did scuff them caliper. So the 1/4” spacer is mandatory. I’m pretty sure the wheel damage is my doing and it’s off that the same damage is on both front wheels. I will be repairing/saving the wheels but in the interest of preventing this from happening in the future, I’ll check a few things like you guys have suggested. And I’ll call JEGS too

__________________

1987 IROC-Z - modified

|

|

|

05-19-2021, 04:40 PM

05-19-2021, 04:40 PM

|

#345

|

|

Mongo the Meet Coordinator

Join Date: May 2008

Posts: 16,900

|

Personally, if those were my wheels they would be hitting the scrap pile asap.

__________________

Quote:

Originally Posted by KirkEvil

repo bigals turd gen and part it out to a loving home

|

|

|

|

05-19-2021, 07:52 PM

05-19-2021, 07:52 PM

|

#346

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

Understood; both sides of keeping/tossing the wheels. Not going to immediately scrap them, I have several months before drag racing again. They are repairable, and thats probably the route I am going to go. Can't afford more new wheels. Been spending too much money on this car recently and I don't make much money at my new job. Roll bar, struts, Falken tires for all 4 corners, race day costs, will need tires mounted and balanced, and then an alignment. If someone wants to buy me new wheels or give me new wheels, thats another story.

Decided to take a closer look at the wheels today. Noticed something that I never took a close enough look at before. Weird. Some kid of machining that removed some of the metal on the hub face. Noticeable difference in the metal height. Hard to see in the pics. Also I included a photo of the spacer that I use, and the ridge that is in the hub face is not from the spacer. It looks actually machined. Wondering if this ridge/step in the metal face caused the hub to repeatedly get tightened strangely enough to distort the wheel and eventually cause a crack.

Check this out. Different material thickness at the wheel hub face. Less material towards the center opening of the wheel, probably a fed thousandths of an inch. Why would this exist?

__________________

1987 IROC-Z - modified

Last edited by IROCZman15; 05-19-2021 at 07:54 PM.

|

|

|

05-19-2021, 09:22 PM

05-19-2021, 09:22 PM

|

#347

|

|

Lord of the rings / 10 Second Club / Meet Coordinator

Join Date: Aug 2004

Location: Millstone Township, NJ

Posts: 6,361

|

Don't be offended but I'd guess this is just the quality of a cheaper wheel cast and then machined to do it's job. Tolerances won't be perfect. Perhaps the spacers aren't perfectly flat either which could cause uneven stress on the wheel resulting in cracks from you tightening them past recommended. I recall the aluminum wheels in my grandfather's XJS jag being so soft that they would bend if you didn't torque them down right.

In any case, I agree that I'd be concerned with running them with 40 ft lbs on the lugs but going beyond what's recommended could likely lead toward more cracking. Food for thought and recognizing funds aren't there for new wheels. Perhaps fix and sell these and maybe a different set will pop pup that will not be a stretch on the wallet.

__________________

97 T/A Ram Air Convt

97 T/A Ram Air Convt

Forever dyno queen / 777rwhp 662 rwtq @ 17lbs / 10.2 @ 140

'24 Corvette Z06

17 Sierra 2500HD Dmax

81 Turbo TA

|

|

|

05-20-2021, 07:54 PM

05-20-2021, 07:54 PM

|

#348

|

|

10 Second Club / Meet Coordinator

Join Date: Dec 2004

Location: Roxbury, NJ

Posts: 2,116

|

no, not offended at all. I am always in search of tech advice and opinions from those who know mroe than me, so I would not get offended. I tend to write a LOT in my posts but only in an effort to put as much info out there and avoid any back-and-forth questions regarding a topic that I could just simply type out initially.

Yup, I agree, it is probably a combination of cheap cast Jegs wheels, that odd machined grove on the back of the hub, maybe an imperfection that is/was on one of the spacers, and me slightyl overtightening them. I could see it being more prone to damage if I rammed them on with an impact gun on the max setting, but thats not the case.

I had done some re3asearch too, and also a friend mentioned that usually for wheel tightness specs, its not so much the wheel that dictates the torque specs, its the torque rating of the lug stud. usually 12 mm and 1/2 studs are in the 80-120 range depending on which entity you find your info from.

Yup, I am going to keep my options open for a while. I was fortunate enough to pickup a free Miller Tig Welder and a free Linde Mig welder and I just finished installing a 100 amp 220 volt subpanel in the garage. I bought some welding equipment, a mixed gas cylinder and a pure argon cylinder and have just gotten a change to start playing around with those welders. Just fired up the Tig welder for the first time ever just this afternoon after work. Might get some practice in during the next few months and see how I can attack the wheel repair. if it doesn't seem to work, well, then the wheels just were not meant to be. Yea, we could all say that bringing them somewhere is an option too, but if I just caved in and brought my car to a repair place every time it needed something, well I would not enjoy this hobby very much at all. I'll see. Not overly concerned at this point really.

__________________

1987 IROC-Z - modified

|

|

|

05-21-2021, 07:01 AM

05-21-2021, 07:01 AM

|

#349

|

Join Date: Nov 2007

Location: Jackson, NJ

Posts: 1,724

|

Have you ever Tig welded before?

Regardless I think you can handle the repair with a little practice before hand.

__________________

1983 camaro- Scrap

1988 camaro- Also scrap

'05 Silverado- You guessed it, scrap

1988 TRX 250R- Ported w/ high compression on 110 octane- Out 60' your LT1

Jersey Shore Street Car Takeover (JSSCT) Founder

Quote:

Originally Posted by LS1ow

and once i get PHB, what do i ajust it too?

|

Quote:

Originally Posted by Jersey Mike

Seven.

|

|

|

|

05-21-2021, 07:14 AM

05-21-2021, 07:14 AM

|

#350

|

Join Date: Oct 2008

Posts: 586

|

Kenvil welding down the road from you can fix these.

Before you fix these yourself, practice not only Tig welding but also the fun of welding cast aluminum. It is doable but a dirty casting can make the job 'fun'.

Dirty meaning used / run through mud & physically dirty when made or porous. Also a beginner's tip when welding thick aluminum, its a big ice cube & will suck up heat leaving you with a nice cold booger weld. Adjust your settings accordingly.

Last edited by TaKid455; 05-21-2021 at 07:18 AM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|

|