|

View Poll Results: WHats your favorite type of welding?

|

|

Arc (stick)

|

|

4 |

13.79% |

|

MIG

|

|

13 |

44.83% |

|

TIG

|

|

9 |

31.03% |

|

Gas

|

|

1 |

3.45% |

|

Forge

|

|

1 |

3.45% |

|

Other type

|

|

1 |

3.45% |

|

10-19-2007, 10:30 PM

10-19-2007, 10:30 PM

|

#1

|

Join Date: Jul 2007

Location: Middlesex, NJ

Posts: 462

|

Whats your favorite type of welding?

Although im still a beginner, im really getting into welding lately and i talk to alot of people about it and its interesting to here peoples preferences. Now ofcourse some type of welding machines are better for some jobs while not for the others but any welders got there favorites and im sure theres plenty on this board.

Its tough for me to pick one but if i had to pick out what i have used so far it would have to be Arc welding. Its a little more difficult then most other types but once you get it down its fun. My favorite rod is the 7018

I love explosion welding as well but i dont think im gonna be doing that anytime soon haha

__________________

Harry (Proud member of NJFB) www.myspace.com/newjerseyfbodies

1986 FireBird LG4 www.myspace.com/newjerseyfbodies

1986 FireBird LG4

-FlowMaster 3inch American Thunder -Edelbrock Elite Series Intake -WS6 Style Functional Ram Air Hood -B&M Shift Kit -American Racing Outlaw II Alloys -Fuzion HRI Tires

8/26/07 Just reached 160K and running great!

1/15/09 Just reached 180K and still running great!

Last edited by Predator86; 10-19-2007 at 10:34 PM.

|

|

|

10-19-2007, 10:47 PM

10-19-2007, 10:47 PM

|

#2

|

Join Date: Feb 2007

Location: Wantage, NJ

Posts: 693

|

I'm a new welder, too. When I decided it was time to step up and buy a welder back in March, I decided to go mig. I'm running a Hobart that's capable of up to 1/4" steel on house current without the bottle. I'm using the flux core right now; as I'm still learning I haven't thrown the bottle into the equation yet.

I like my mig because it's easy as heel. Adjust the settings for the proper width of metal, then point and shoot. Clean up the slag with a flap disc and call it done. And I didn't have to install a 220 box to run it. Just gotta be careful when welding sheetmetal, but that's a learning process.

So far, I've built a front bumper and rear tire carrier for my Jeep. It doesn't look great, but it sure is strong! Good times!

|

|

|

10-20-2007, 12:05 AM

10-20-2007, 12:05 AM

|

#3

|

|

Banned Camp Director Emeritus

Join Date: Aug 2004

Location: Somerset County

Posts: 8,395

|

I voted for TIG. I could have voted for MIG because it is very easy and very practical, but I have more fun with TIG welding. one of these years I'll buy a TIG rig....one of these years....

edit

I really dislike arc welding. its not nearly as accurate as mig/tig.

__________________

Quote:

Originally Posted by baddest434

and 1 more smart ass answer by you and i'm going to reach into this monitor and grab you by the throat

|

Last edited by Ian; 10-20-2007 at 12:32 PM.

|

|

|

10-20-2007, 01:34 AM

10-20-2007, 01:34 AM

|

#4

|

|

14 Second Club

Join Date: Feb 2007

Location: New Milford

Posts: 650

|

arc welding is like blowing snot compared to any other type of welding. hence its use on non precision industrial things (fixing bulldozers, etc)

__________________

FAA Airframe and Powerplant Mechanic - Republic Airlines

-1980 Trans Am ZZ383 stroker

-2012 Ford Focus 5spd

-1989 Harley Softail Custom

-2000 Trans Am, M6, WS6 *SOLD* *RIP*

|

|

|

10-20-2007, 08:55 AM

10-20-2007, 08:55 AM

|

#5

|

|

13 Second Club

Join Date: Feb 2007

Posts: 875

|

stick welding is getting to be a lost art. anyone who says its not precise or ugly has no clue what theyre talking about. im a pipefitter, certified in stick and heli-arc (tig). i can pass any bend test or x-ray you throw at me. if you think stick welding is ugly, ill show you what i can do, and youll be damned if you can tell the differance between a good, quality stick welder and mig.

__________________

yes, my hog is bigger then yours

|

|

|

10-20-2007, 09:27 AM

10-20-2007, 09:27 AM

|

#6

|

Join Date: Jan 2007

Posts: 5,623

|

I had to say forge cause I've always wanted to learn how to make swords

__________________

2000 Tahoe Z71 5.7

1982 Z28 Pacecar 305

1999 S10

|

|

|

10-20-2007, 12:32 PM

10-20-2007, 12:32 PM

|

#7

|

|

Banned Camp Director Emeritus

Join Date: Aug 2004

Location: Somerset County

Posts: 8,395

|

Quote:

Originally Posted by EchoMirage

stick welding is getting to be a lost art. anyone who says its not precise or ugly has no clue what theyre talking about. im a pipefitter, certified in stick and heli-arc (tig). i can pass any bend test or x-ray you throw at me. if you think stick welding is ugly, ill show you what i can do, and youll be damned if you can tell the differance between a good, quality stick welder and mig.

|

let me clarify. stick welding is not precise enough for the automotive field. I also think its unfair to say that those who knock stick welding "dont have a clue". for welding pipes and large pieces of metal, its great. but for sheet metal, aluminum and roll cage tubing, its not really an option.

I personally have no intentions of welding up household or industrial plumbing, so that type of welding is useless to me.

__________________

Quote:

Originally Posted by baddest434

and 1 more smart ass answer by you and i'm going to reach into this monitor and grab you by the throat

|

|

|

|

10-20-2007, 01:13 PM

10-20-2007, 01:13 PM

|

#8

|

|

Ayatollah of Rock N Rolla / Admin

Join Date: Mar 2006

Location: Parts Unknown

Posts: 12,573

|

Quote:

Originally Posted by Ian

I voted for TIG. I could have voted for MIG because it is very easy and very practical, but I have more fun with TIG welding. one of these years I'll buy a TIG rig....one of these years....

edit

I really dislike arc welding. its not nearly as accurate as mig/tig. |

Agreed.

Although I voted for MIG since it's cheaper for hacks like me.

|

|

|

10-20-2007, 02:31 PM

10-20-2007, 02:31 PM

|

#9

|

Join Date: Jul 2007

Location: Middlesex, NJ

Posts: 462

|

Quote:

Originally Posted by EchoMirage

stick welding is getting to be a lost art. anyone who says its not precise or ugly has no clue what theyre talking about. im a pipefitter, certified in stick and heli-arc (tig). i can pass any bend test or x-ray you throw at me. if you think stick welding is ugly, ill show you what i can do, and youll be damned if you can tell the differance between a good, quality stick welder and mig.

|

I totally agree with you. Pretty much anyone can pick up a mig and go to town but it takes a true artist to master the stick. But once you got it down ya cant even tell the difference...ive seen some of the most clean and beautiful welds come from them and still be strong as hell.

And its true they dont really use it in the automotive fields but u can if know how. Another reason mig is so popular with the auto-mechanics is because of the assembly line process, hell of alot quicker then the stick.

__________________

Harry (Proud member of NJFB) www.myspace.com/newjerseyfbodies

1986 FireBird LG4 www.myspace.com/newjerseyfbodies

1986 FireBird LG4

-FlowMaster 3inch American Thunder -Edelbrock Elite Series Intake -WS6 Style Functional Ram Air Hood -B&M Shift Kit -American Racing Outlaw II Alloys -Fuzion HRI Tires

8/26/07 Just reached 160K and running great!

1/15/09 Just reached 180K and still running great!

|

|

|

10-20-2007, 03:42 PM

10-20-2007, 03:42 PM

|

#10

|

|

11 Second Club

Join Date: Feb 2006

Posts: 932

|

I've seen people with stick welders, make them look as good as a TIG weld. Now on the other hand, I've seen people with TIG welders look like they just picked up a MIG for the frist time, screwing arround with it. If you can stick weld, you can do any other kind of welding there is..

__________________

2004 GTO GMM shifter Spohn stuff, tint and my love......

1988 Camaro Vert -Sold

Last edited by Kat; 10-20-2007 at 03:42 PM.

|

|

|

10-20-2007, 05:10 PM

10-20-2007, 05:10 PM

|

#11

|

|

13 Second Club

Join Date: Feb 2007

Posts: 875

|

Quote:

Originally Posted by Kat

I've seen people with stick welders, make them look as good as a TIG weld. Now on the other hand, I've seen people with TIG welders look like they just picked up a MIG for the frist time, screwing arround with it. If you can stick weld, you can do any other kind of welding there is..

|

agreed, but just because you might be a good stick welder, doesnt mean you can be a good TIGer. ive seen first hand, people who can stick weld decently well, pick up a tig machine and look like bird **** on pipe. to become a pipefitter, you have to go to school for FIVE YEARS....90% of which is welding. TIG is a total art. any retard can mig weld. stick takes alot of time and practice.......but TIG....either you go it, or you dont. 2 handed welding, walking the cup, controlling your heat/gas/cup size......its not for everyone.

__________________

yes, my hog is bigger then yours

|

|

|

10-20-2007, 06:45 PM

10-20-2007, 06:45 PM

|

#12

|

|

11 Second Club

Join Date: Nov 2005

Location: Gloucester

Posts: 863

|

Quote:

Originally Posted by EchoMirage

agreed, but just because you might be a good stick welder, doesnt mean you can be a good TIGer. ive seen first hand, people who can stick weld decently well, pick up a tig machine and look like bird **** on pipe. to become a pipefitter, you have to go to school for FIVE YEARS....90% of which is welding. TIG is a total art. any retard can mig weld. stick takes alot of time and practice.......but TIG....either you go it, or you dont. 2 handed welding, walking the cup, controlling your heat/gas/cup size......its not for everyone.

|

I agree as to tig being an art... I am also a welder and I would have to say that tig is definitely not for everyone because you have to be in full control of all your limbs lol or it will just look like snot.... But, I would have to say that stick is definitely a challenge for the newcomer lol especially just trying to start an arc...

Oh yea, I also love to use the spool gun for aluminum because it is just plain FUN!!

__________________

|

|

|

10-20-2007, 09:53 PM

10-20-2007, 09:53 PM

|

#13

|

|

Token v6 Guy

Join Date: Sep 2004

Location: No longer neon land :(

Posts: 5,703

|

no idea.... i don't weld

__________________

2013 Dodge Challenger SRT8 - 12.079 at 116.45

2010 Ford Taurus SHO - stage 4+ tune and an intake - no times yet

|

|

|

10-21-2007, 03:55 AM

10-21-2007, 03:55 AM

|

#14

|

Join Date: Jul 2007

Location: Middlesex, NJ

Posts: 462

|

Quote:

Originally Posted by Slow 88

But, I would have to say that stick is definitely a challenge for the newcomer lol especially just trying to start an arc

|

o man that can be true lol...that was the first type i learned....ive used many 4 letter words while i was getting the rod stuck to the metal

now i never do

__________________

Harry (Proud member of NJFB) www.myspace.com/newjerseyfbodies

1986 FireBird LG4 www.myspace.com/newjerseyfbodies

1986 FireBird LG4

-FlowMaster 3inch American Thunder -Edelbrock Elite Series Intake -WS6 Style Functional Ram Air Hood -B&M Shift Kit -American Racing Outlaw II Alloys -Fuzion HRI Tires

8/26/07 Just reached 160K and running great!

1/15/09 Just reached 180K and still running great!

|

|

|

10-21-2007, 09:11 AM

10-21-2007, 09:11 AM

|

#15

|

|

11 Second Club

Join Date: Feb 2006

Posts: 932

|

Quote:

Originally Posted by EchoMirage

agreed, but just because you might be a good stick welder, doesnt mean you can be a good TIGer. ive seen first hand, people who can stick weld decently well, pick up a tig machine and look like bird **** on pipe. to become a pipefitter, you have to go to school for FIVE YEARS....90% of which is welding. TIG is a total art. any retard can mig weld. stick takes alot of time and practice.......but TIG....either you go it, or you dont. 2 handed welding, walking the cup, controlling your heat/gas/cup size......its not for everyone.

|

Ture that! I've been lucky enouh to work with people that are good at those three types of welding.

Tell me about schhol and OJT. Ive been going to school lately for NDT. I still have another year left before I'm done. At least once the course is done I'll be a level II inspector.. lol

__________________

2004 GTO GMM shifter Spohn stuff, tint and my love......

1988 Camaro Vert -Sold

|

|

|

10-21-2007, 10:38 AM

10-21-2007, 10:38 AM

|

#16

|

|

Banned Camp Director Emeritus

Join Date: Aug 2004

Location: Somerset County

Posts: 8,395

|

Quote:

Originally Posted by EchoMirage

agreed, but just because you might be a good stick welder, doesnt mean you can be a good TIGer. ive seen first hand, people who can stick weld decently well, pick up a tig machine and look like bird **** on pipe. to become a pipefitter, you have to go to school for FIVE YEARS....90% of which is welding. TIG is a total art. any retard can mig weld. stick takes alot of time and practice.......but TIG....either you go it, or you dont. 2 handed welding, walking the cup, controlling your heat/gas/cup size......its not for everyone.

|

I agree 100%. MIG is very easy. stick is pretty hard. I'm not gonna lie, I suck at stick welding. TIG is really hard, but I seem to be decent at it.

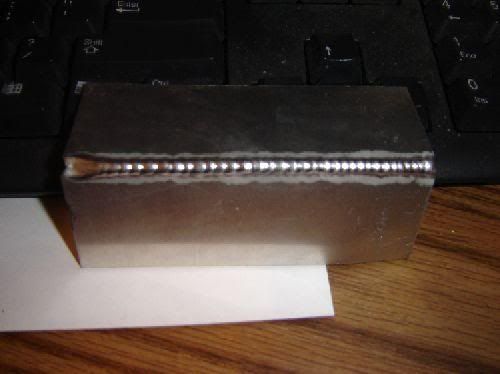

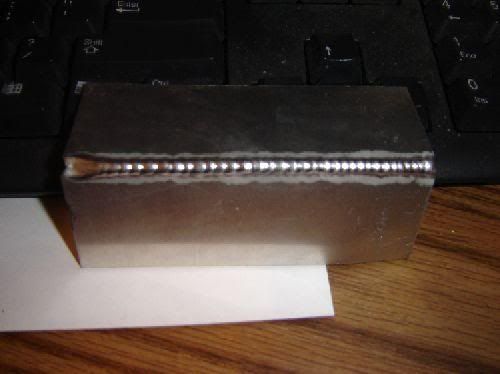

I did this while at school. not my best work, but certainly not my worst!

__________________

Quote:

Originally Posted by baddest434

and 1 more smart ass answer by you and i'm going to reach into this monitor and grab you by the throat

|

|

|

|

10-21-2007, 11:29 AM

10-21-2007, 11:29 AM

|

#17

|

|

11 Second Club

Join Date: Nov 2005

Location: Gloucester

Posts: 863

|

Quote:

Originally Posted by Ian

I agree 100%. MIG is very easy. stick is pretty hard. I'm not gonna lie, I suck at stick welding. TIG is really hard, but I seem to be decent at it.

I did this while at school. not my best work, but certainly not my worst!

|

Looks good, but it looks like you have to ease up a little on the peddle so you don't wash out the corner still the bead looks pretty consistant..

__________________

|

|

|

10-21-2007, 02:51 PM

10-21-2007, 02:51 PM

|

#18

|

|

Banned Camp Director Emeritus

Join Date: Aug 2004

Location: Somerset County

Posts: 8,395

|

yeah, like I said its not my best one, but I have no idea what happened to all my really nice ones. I haven't TIGed in about 3 years so if I were to try that today I'd be a little out of touch

welding aluminum isnt too easy.

__________________

Quote:

Originally Posted by baddest434

and 1 more smart ass answer by you and i'm going to reach into this monitor and grab you by the throat

|

|

|

|

10-21-2007, 07:25 PM

10-21-2007, 07:25 PM

|

#19

|

|

11 Second Club

Join Date: Nov 2005

Location: Gloucester

Posts: 863

|

Quote:

Originally Posted by Ian

yeah, like I said its not my best one, but I have no idea what happened to all my really nice ones. I haven't TIGed in about 3 years so if I were to try that today I'd be a little out of touch

welding aluminum isnt too easy. |

I wasn't making fun of your work....As a matter of fact I complimented it...Trust me I weld day in and day out and there is times when I have to weld cracked oil pans or intakes and if you don't clean it really well you'll be cussing in no time!!

__________________

|

|

|

10-21-2007, 10:35 PM

10-21-2007, 10:35 PM

|

#20

|

|

Banned Camp Director Emeritus

Join Date: Aug 2004

Location: Somerset County

Posts: 8,395

|

I know you werent making fun of it, I just said that so other who have never tiged aluminum would realize its not nearly as easy as welding steel. besides, out of everyone here, you one of the few people qualified to make fun of it

__________________

Quote:

Originally Posted by baddest434

and 1 more smart ass answer by you and i'm going to reach into this monitor and grab you by the throat

|

|

|

|

10-22-2007, 10:25 AM

10-22-2007, 10:25 AM

|

#21

|

|

King of Free

Join Date: Sep 2005

Posts: 1,750

|

the kind that don't break : )

__________________

2001 Trans Am M6 WS6 Black on Black...on Black

PaceSetter LT's, TSP catted Y,Borla catback, SLP lid

!CAGS, Eibach pro-kit, Bilstein shocks, 5% tint all around

|

|

|

10-24-2007, 11:17 AM

10-24-2007, 11:17 AM

|

#22

|

Join Date: Jul 2007

Location: Middlesex, NJ

Posts: 462

|

Quote:

Originally Posted by ryanfx

the kind that don't break : )

|

thats what all of the good welders look for....but really a weld is stronger than the metal around it....so in most cases the weld dosent fail but the surrounding metal does

__________________

Harry (Proud member of NJFB) www.myspace.com/newjerseyfbodies

1986 FireBird LG4 www.myspace.com/newjerseyfbodies

1986 FireBird LG4

-FlowMaster 3inch American Thunder -Edelbrock Elite Series Intake -WS6 Style Functional Ram Air Hood -B&M Shift Kit -American Racing Outlaw II Alloys -Fuzion HRI Tires

8/26/07 Just reached 160K and running great!

1/15/09 Just reached 180K and still running great!

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

|

|

|